Quick-setting early-strength grouting material

A technology of grouting materials and raw materials, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems such as difficult control of setting time, achieve the goal of improving resistance to groundwater erosion, reducing production costs, and reducing the amount of addition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

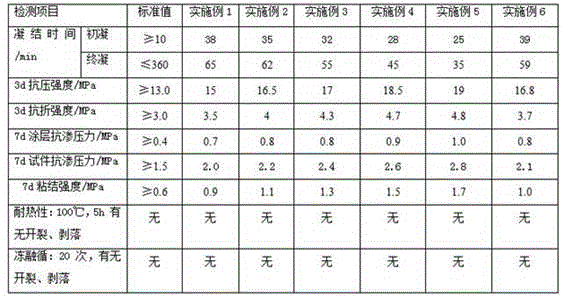

Examples

Embodiment 1

[0021] A fast-setting early-strength grouting material, comprising the following raw materials in parts by weight: 75 parts of Portland cement clinker; 10 parts of slag; 5 parts of sulphoaluminate cement; 1 part of silica fume; 0.5 parts of bentonite; 0.05 parts of base cellulose ether; 0.25 parts of water reducing agent; 0.005 parts of lithium carbonate; 0.05 parts of defoamer.

Embodiment 2

[0023] A fast-setting early-strength grouting material, comprising the following raw materials in parts by weight: 78 parts of Portland cement clinker; 8 parts of slag; 8 parts of sulphoaluminate cement; 2 parts of silica fume; 1 part of bentonite; 0.1 part of base cellulose ether; 0.3 part of water reducing agent; 0.01 part of lithium carbonate; 0.15 part of defoamer.

[0024] In this embodiment, the specific surface area of the slag is 400 kg / m3; the sulphoaluminate cement is sulphoaluminate cement with a strength grade of 42.5.

Embodiment 3

[0026] A fast-setting early-strength grouting material, comprising the following raw materials in parts by weight: 80 parts of Portland cement clinker; 6 parts of slag; 10 parts of sulphoaluminate cement; 3 parts of silica fume; 2 parts of bentonite; 0.15 parts of base cellulose ether; 0.35 parts of water reducing agent; 0.03 parts of lithium carbonate; 0.2 parts of defoamer.

[0027] In this embodiment, the specific surface area of slag is 800kg / m3; the sulphoaluminate cement is the sulphoaluminate cement whose strength grade is 52.5; the specific surface area of silica fume is 30000cm 2 / g; bentonite is sodium-based bentonite, its water absorption rate is greater than 300%, and the sieve residue of 80μm is less than 8%; the viscosity of hydroxyethyl cellulose ether is 50000mPa·s; The water rate is 25%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com