Aluminate cement-based jet mortar and preparation method thereof

A technology of aluminate cement and Portland cement, which is applied in the field of mining, can solve the problems that the rapid setting performance of spray mortar cannot meet the construction requirements, and is easy to shrink and crack, and achieves fast setting and hardening speed, high early strength and low production cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of aluminate cement-based spray mortar of the present invention comprises the following steps:

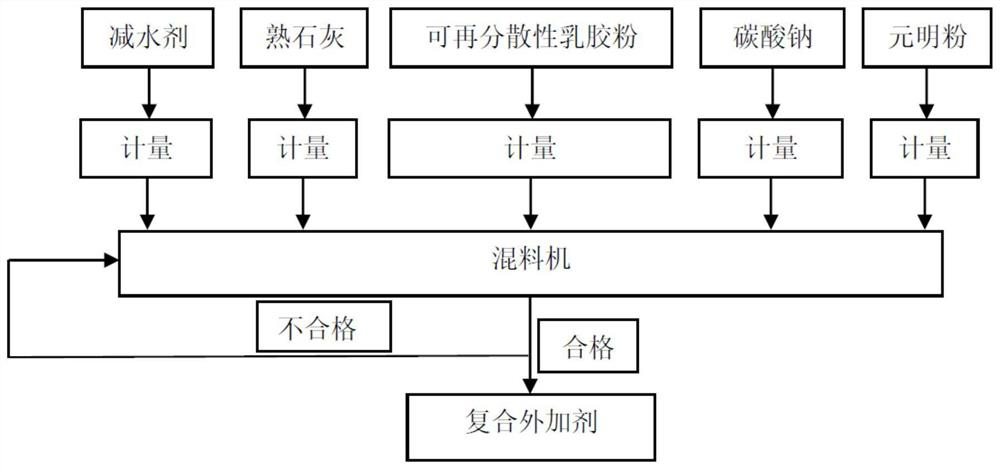

[0043] In the first step, add water reducer, slaked lime, sodium carbonate, sodium sulfate, and redispersible latex powder into the mixer in proportion and mix evenly, and set the setting time according to the national standard GB 8076-2008 "Concrete Admixture" After testing, the composite admixture is obtained after passing the test. The preparation process is as follows: figure 1 shown;

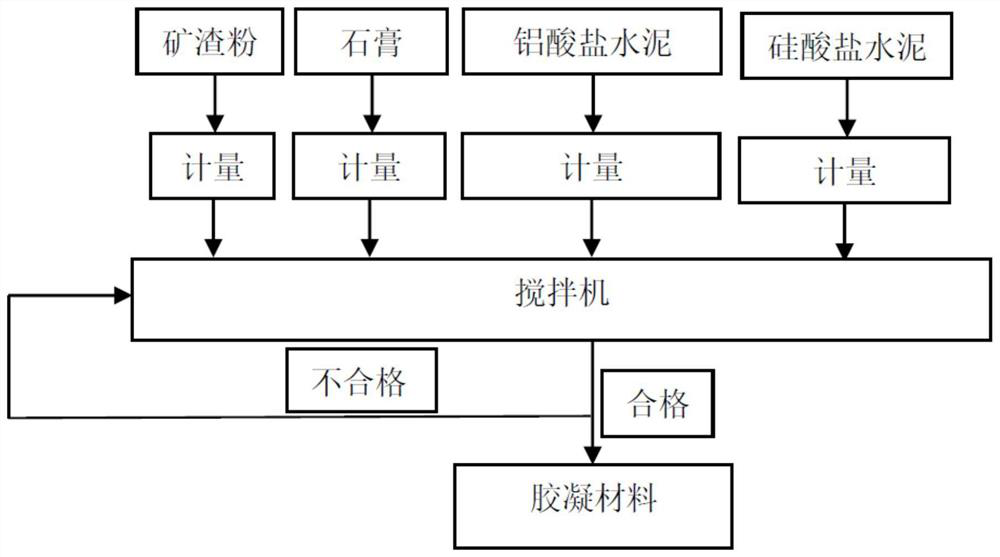

[0044] In the second step, add aluminate cement, Portland cement, slag powder, and gypsum into the mixer in proportion, and stir until uniform. Refer to the national standard GB 8076-2008 "Concrete Admixtures" to test the setting time and compressive strength , after passing the test, the gelled material is obtained. The preparation process is as follows: figure 2 shown;

[0045] In the third step, the composite admixture obtained in the first step, the cementitio...

Embodiment 1

[0047] The aluminate cement-based spray mortar of this embodiment is prepared as follows:

[0048] In the first step, add 3000g of water reducer, 2000g of slaked lime, 2000g of sodium carbonate, 2000g of sodium bicarbonate, and 1000g of redispersible latex powder into the mixer and mix evenly. Refer to the national standard GB

[0049] 8076-2008 "Concrete Admixture" is tested, and the composite admixture is obtained after passing the test;

[0050] In the second step, mix 3000g of aluminate cement, 3000g of Portland cement, 2000g of slag powder, and 2000g of gypsum in a mixer until they are evenly mixed. Test with reference to the national standard GB 8076-2008 "Concrete Admixture", and pass the test Get gelling material;

[0051] In the third step, the composite admixture obtained in the first step, the cementitious material obtained in the second step, sand and water are proportioned in parts by weight: cementitious material: composite admixture: sand: water=1: 0.045∶2.5∶0...

Embodiment 2

[0053] The aluminate cement-based spray mortar of this embodiment is prepared as follows:

[0054] In the first step, add 2500g of water reducer, 3000g of slaked lime, 1000g of sodium carbonate, 3000g of sodium bicarbonate, and 500g of redispersible latex powder into the mixer and mix evenly. Refer to the national standard GB 8076-2008 "Concrete Admixture" Testing is carried out, and the composite admixture is obtained after passing the testing;

[0055] In the second step, mix 2000g of aluminate cement, 4000g of Portland cement, 1000g of slag powder, and 3000g of gypsum in a mixer until they are evenly mixed. Test with reference to the national standard GB 8076-2008 "Concrete Admixture" and pass the test Get gelling material;

[0056] In the third step, the composite admixture obtained in the first step, the cementitious material obtained in the second step, sand and water are proportioned in parts by weight: cementitious material: composite admixture: sand: water=1: 0.04∶1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com