Wax finishing emulsion and preparation method thereof

A preparation method and technology of wax emulsion, which is applied in the field of leather processing, can solve the problems of poor treatment effect and inability to form multi-color effect, and achieve the effect of low cost, less raw material usage and good emulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

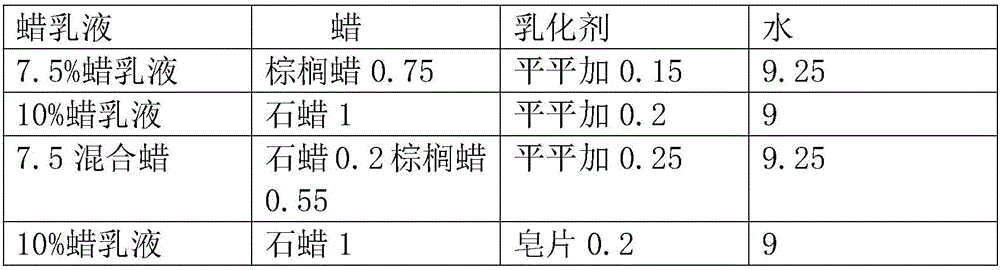

[0016] A wax emulsion for painting, the wax content in the wax emulsion is 7.5% (percentage by weight); in parts by weight, the wax emulsion is prepared from 0.75 parts of palm wax, 0.15 parts of Pingpingjia, and 9.25 parts of boiling water (100 ° C);

[0017] The preparation method is: add 0.75 parts of palm wax into the container and heat it to 60°C to melt it. When the wax is heated to smoke, add 0.15 parts of Pingping plus emulsifier, stop heating after the emulsifier is dissolved, drop into boiling water, and then Heating to boiling and filtering to obtain a wax emulsion, the filtering method is an existing conventional filtering method.

[0018] Poorly emulsified wax does not disperse in cold water and sinks to the bottom of the water. On the contrary, it disperses in flocculent form and emulsifies well.

Embodiment 2

[0020] A wax emulsion for painting, the wax content in the wax emulsion is 10% (percentage by weight); in parts by weight, the wax emulsion is prepared from 1 part of paraffin wax, 0.2 part of flat wax, and 9 parts of boiling water (100 ° C);

[0021] The preparation method is: add 1 part of paraffin wax into the container and heat it to 63°C to melt it. When the wax is heated to smoke, add 0.2 part of Pingping plus emulsifier, stop heating after the emulsifier dissolves, drop into boiling water, and then heat To boiling, the wax emulsion was obtained by filtration.

Embodiment 3

[0023] A wax emulsion for painting, the wax content in the wax emulsion is 7.5% (percentage by weight); by weight, the wax emulsion is composed of 0.2 part of paraffin wax, 0.55 part of palm wax, 0.25 part of Pingpingjia, 9.25 parts of boiling water (100 ℃) formulated;

[0024] The preparation method is: add 0.2 parts of paraffin wax and 0.55 parts of palm wax into the container and heat it to 57°C to melt it. When the wax is heated to smoke, add 0.25 parts of Pingping plus emulsifier, stop heating after the emulsifier is dissolved, and drop in 9. After 25 parts of boiling water, heat to boiling and filter to obtain wax emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com