Ribbed concrete column with built-in high-strength or super-strength concrete core column

A technology of ultra-high-strength concrete and reinforced concrete, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of large cross-section size and difficult construction of joints, and achieve the effects of saving steel, easy guarantee of project quality, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

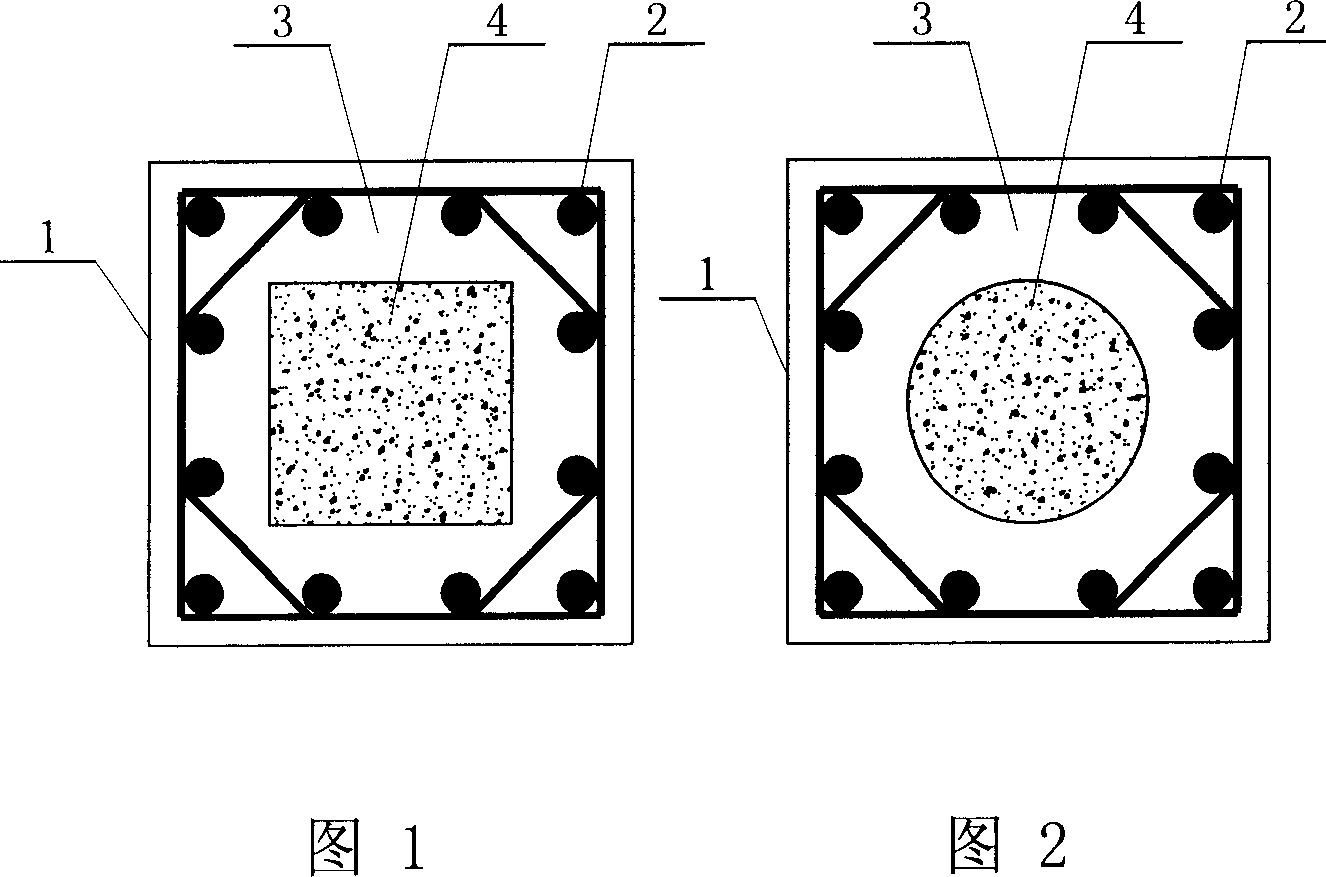

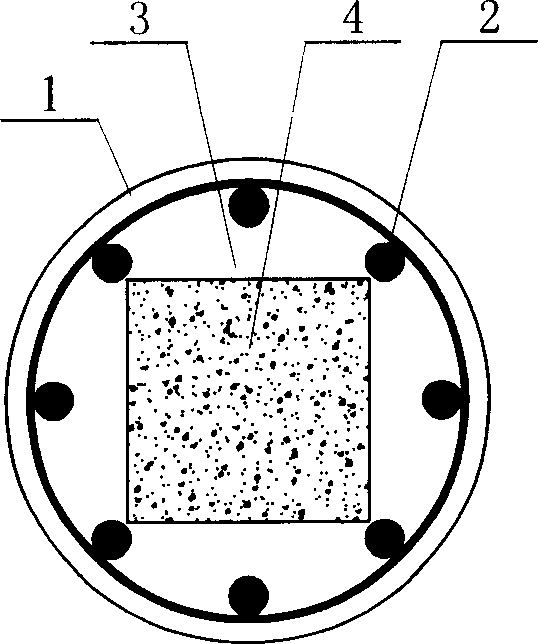

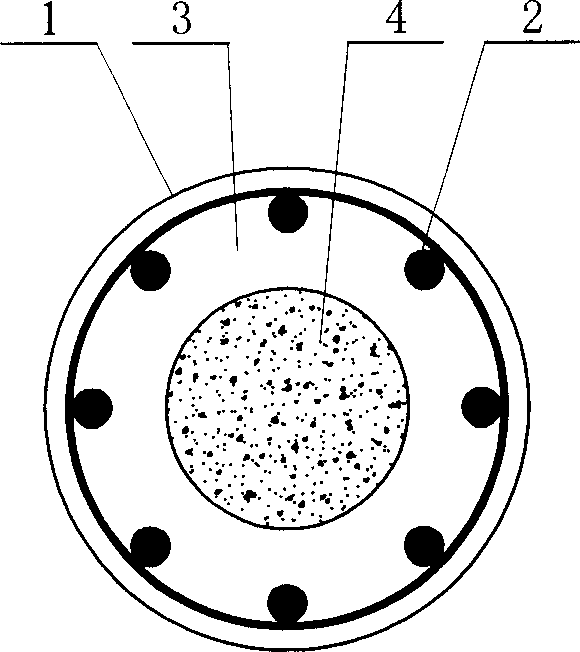

[0007] Specific embodiment 1: This embodiment consists of a peripheral ordinary reinforced concrete column 1, which is composed of steel bars 2 and concrete 3. A high-strength or ultra-high-strength concrete core column 4 in the longitudinal direction of the reinforced concrete column 1 .

[0008] The function of the built-in high-strength or ultra-high-strength concrete core column 4 is mainly to bear the axial pressure, and the function of the peripheral reinforced concrete column 1 is mainly to bear the bending moment.

specific Embodiment approach 2

[0009] Specific Embodiment 2: This embodiment will be described in conjunction with FIG. 1 . In this embodiment, the outer cross-section of the column is a rectangular reinforced concrete column 1 and the core cavity of the rectangular outer ordinary reinforced concrete column 1 is built with a high-strength or ultra-high-strength concrete with a rectangular cross-section that runs through the length direction of the outer ordinary reinforced concrete column 1. Stem 4 is made.

specific Embodiment approach 3

[0010] Specific Embodiment Three: This embodiment will be described in conjunction with FIG. 2 . In this embodiment, the outer cross section of the column is a rectangular outer ordinary reinforced concrete column 1 and the core cavity of the rectangular outer outer ordinary reinforced concrete column 1 is built with a high-strength or The core column 4 is made of ultra-high strength concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com