Prefabricated hollow steel-reinforced concrete column and splicing structure and splicing method thereof

A concrete column and concrete technology, applied in the direction of columns, piers, pillars, etc., can solve the problems of construction speed and resource consumption, and achieve the production environment and labor protection facilities, protection of safety and health, and good applicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in further detail below in conjunction with accompanying drawing:

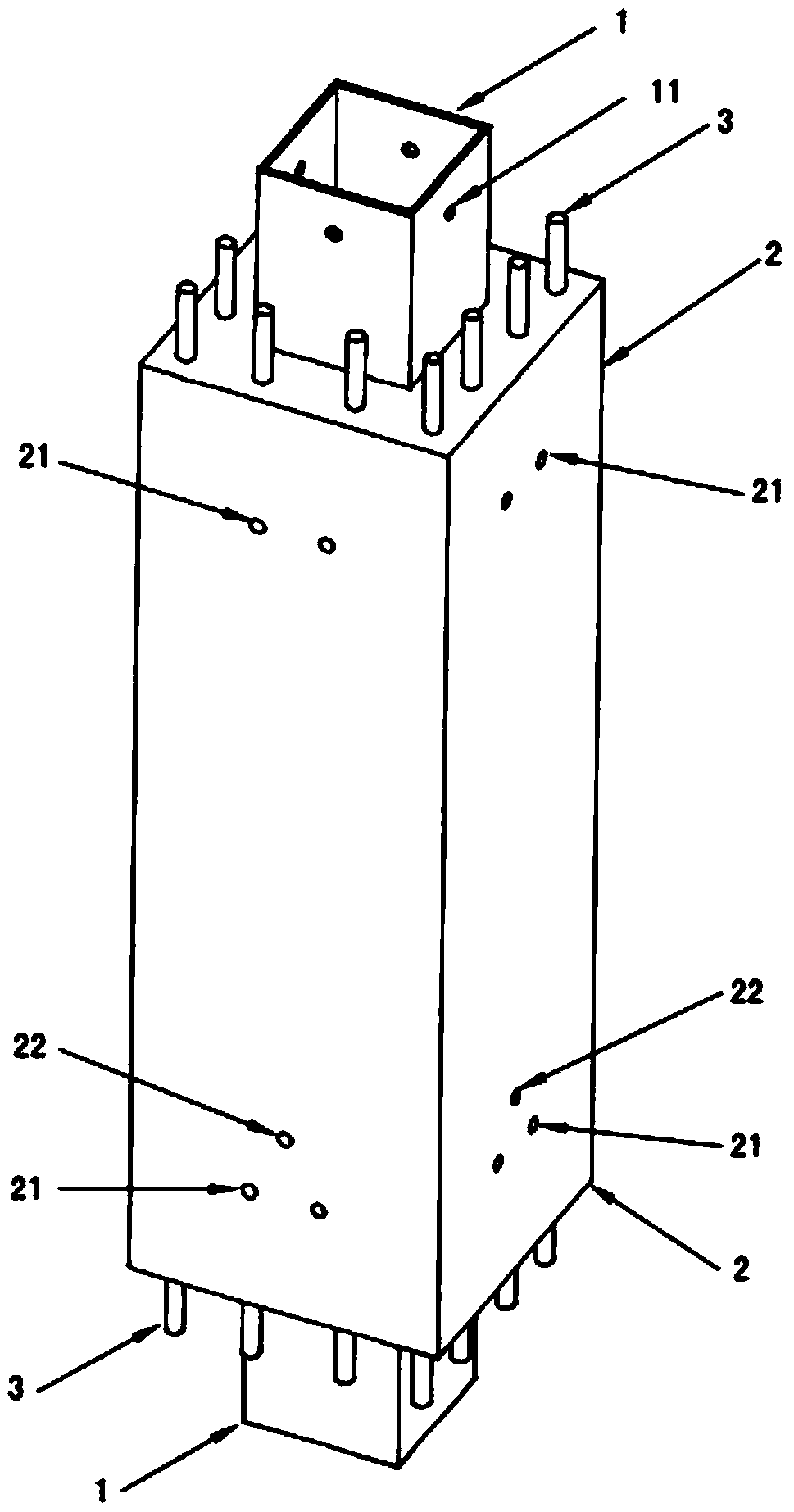

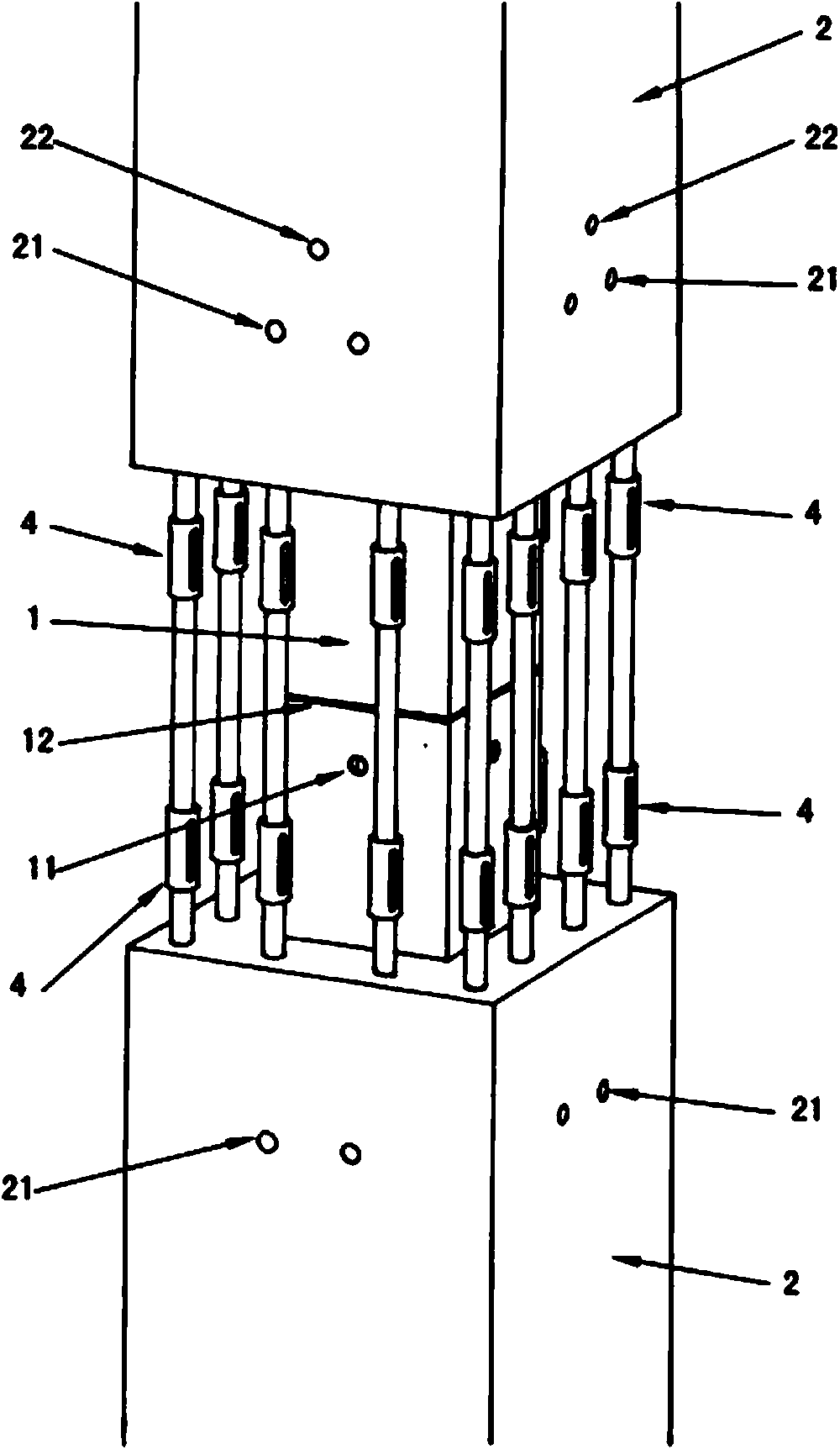

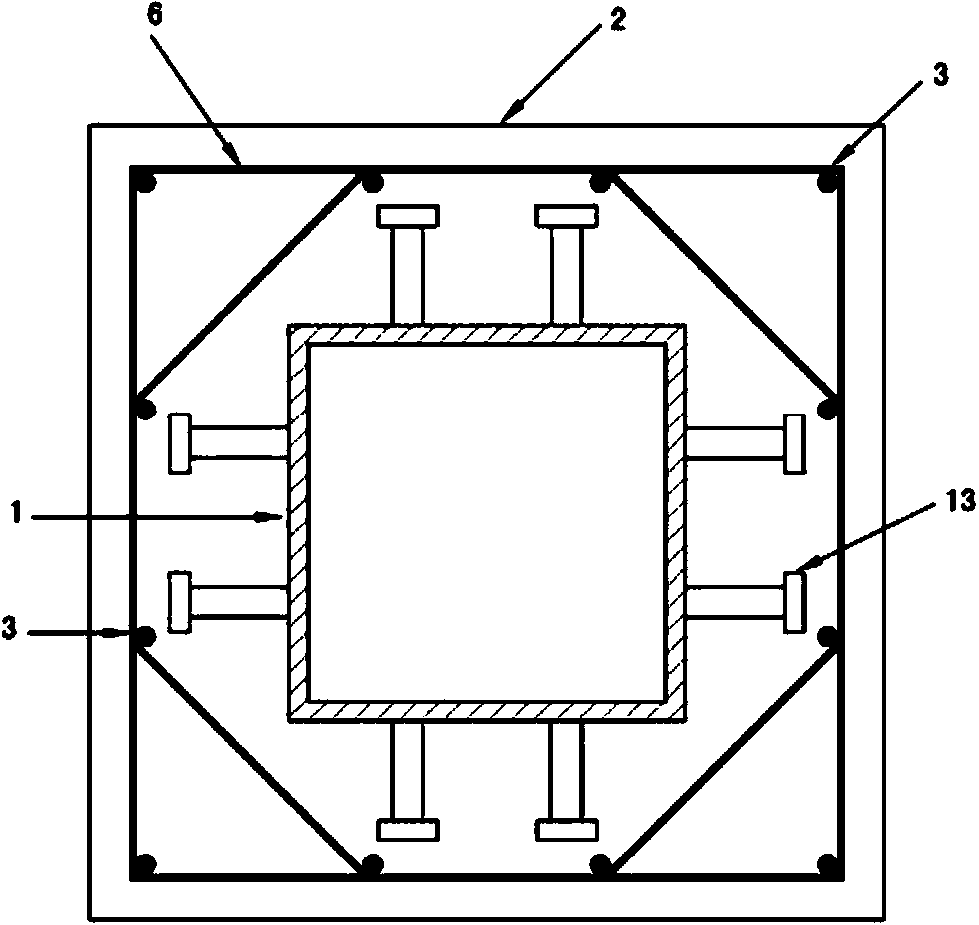

[0037] refer to figure 1 and image 3 , the prefabricated hollow steel concrete column of the present invention comprises a central steel pipe 1, concrete 2, several longitudinal reinforcement bars 3 and stirrups 6 bound on the longitudinal reinforcement bars 3; the longitudinal reinforcement bars 3 are evenly arranged around the central steel pipe 1 The stirrups 6 are evenly bound vertically on the longitudinal reinforcement 3, the central steel pipe 1, the longitudinal reinforcement 3 and the stirrup 6 are all wrapped in the concrete 2, the two ends of the central steel pipe 1 and the longitudinal reinforcement 3 are both Extending out of the upper and lower ends of the concrete 2, the length of the central steel pipe 1 protruding from the end face of the concrete 2 is greater than the length of the longitudinal steel bar 3 protruding from the end face of the concre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com