Steel joint precast and assembled reinforced concrete frame structure

A reinforced concrete and prefabricated assembly technology, which is applied in building structure and construction, can solve the problems of inconvenient installation, low seismic performance, and difficulty in replacing components after disasters, and achieve convenient installation, simplified installation operation, good ductility and seismic energy consumption effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

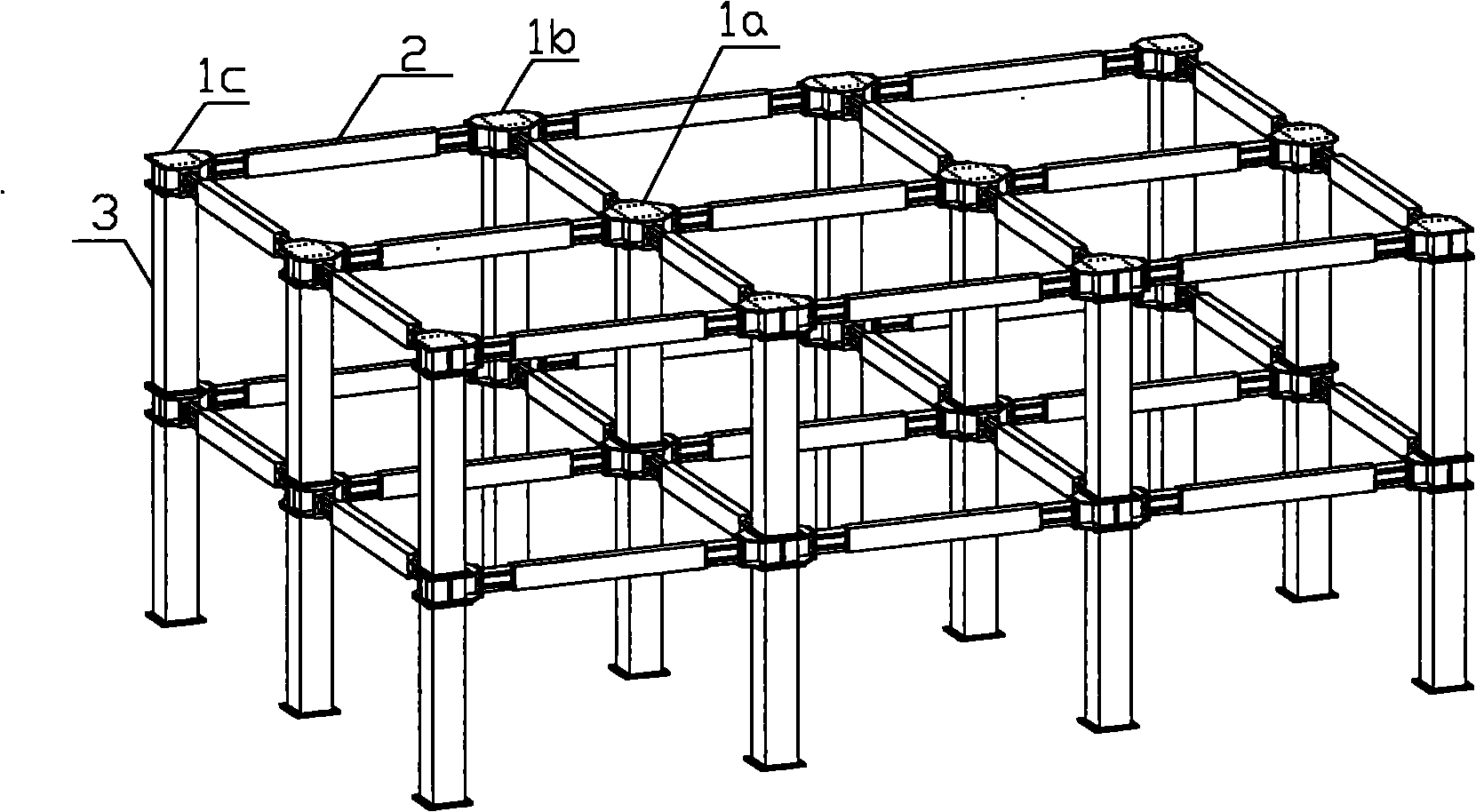

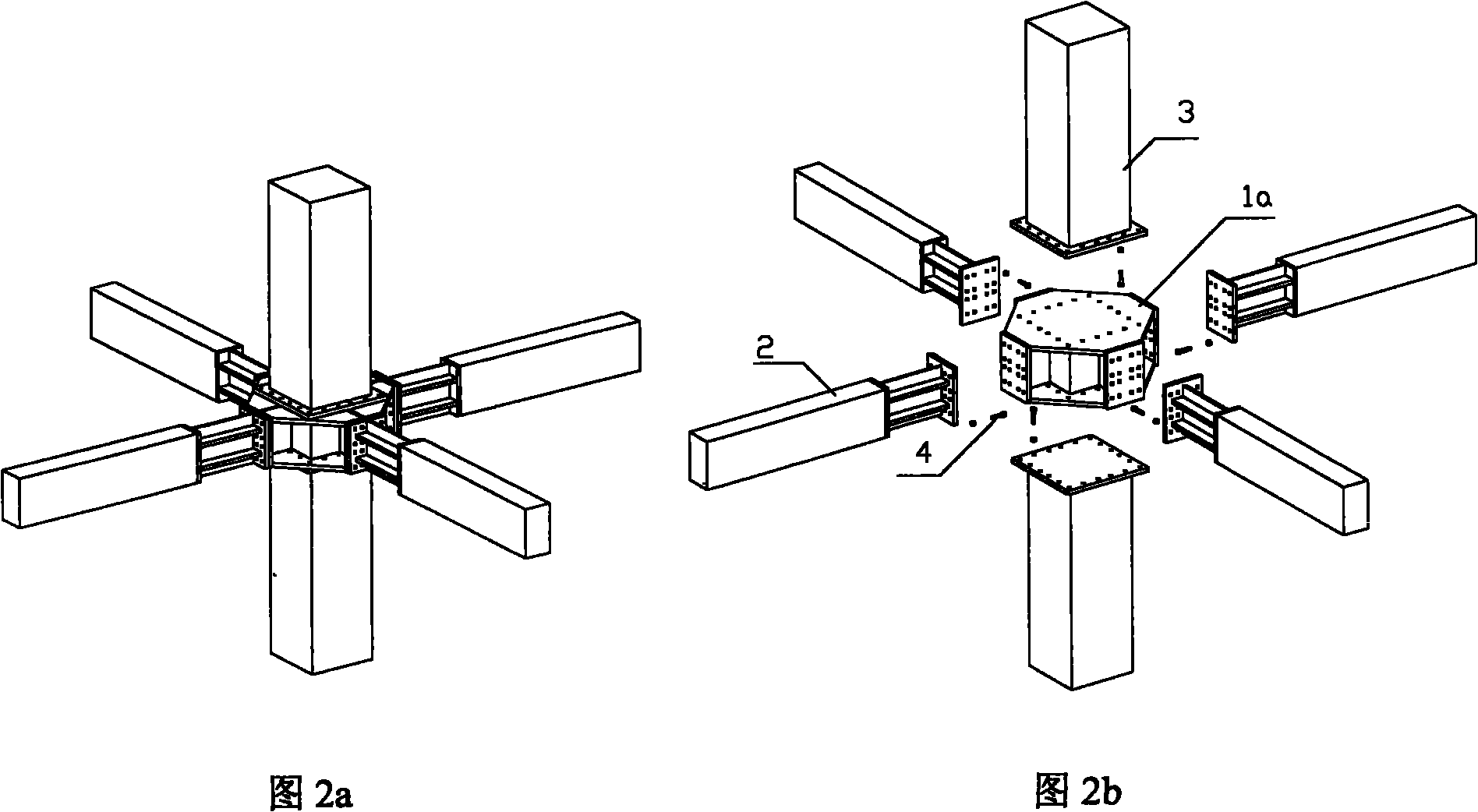

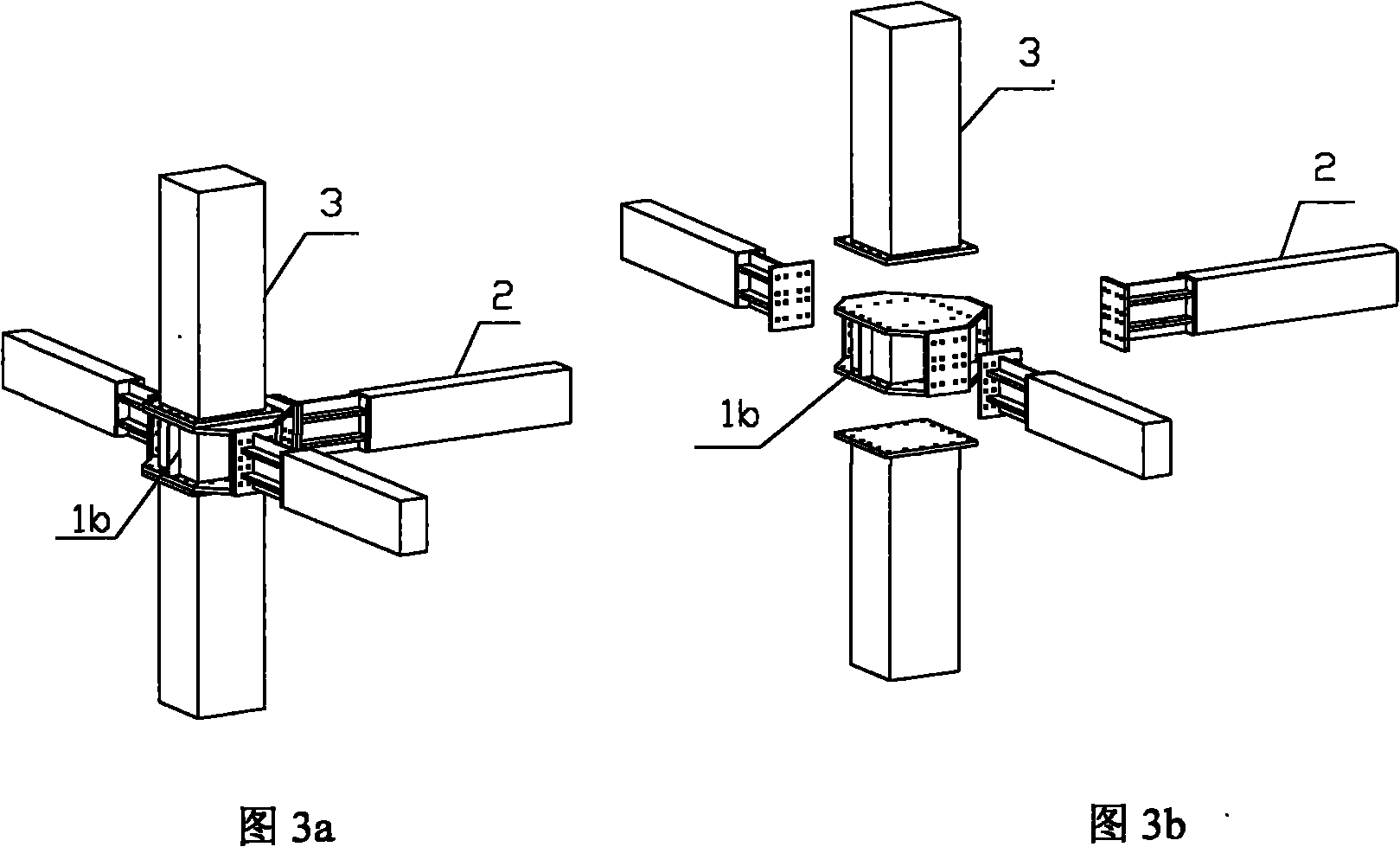

[0028] The invention utilizes a clear node concept to construct prefabricated column and beam connections centered on independent steel nodes, and uses steel nodes with higher rigidity and ductility as node load-bearing members to realize rapid and seismic connection of columns and beams, and post-earthquake The repair of locally damaged components is more flexible and convenient, and a new type of prefabricated reinforced concrete frame structure with steel nodes is formed.

[0029] The prefabricated reinforced concrete frame structure with steel nodes includes: prefabricated beam members 2, prefabricated column members 3 and steel nodes. The steel nodes include a first steel node 1a, a second steel node 1b and a third steel node 1c.

[0030] The first steel node 1a includes a steel plate box body 5, and an annular horizontal reinforcing rib 6 and a vertical reinforcing rib plate 7 are arranged in the steel plate box body 5, and upper bearings are respectively arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com