Novel method for quickly assembling low-cost energy-saving house with prefabricated pole, beam, plate

A technology for energy-saving houses and prefabricated columns, which can be applied to buildings, building structures, etc., can solve the problems of reducing the living area, long construction period, and windows that cannot be too large, so as to reduce the cross-sectional area and weight, and reduce the amount of manual labor. , The effect of energy saving of external wall area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

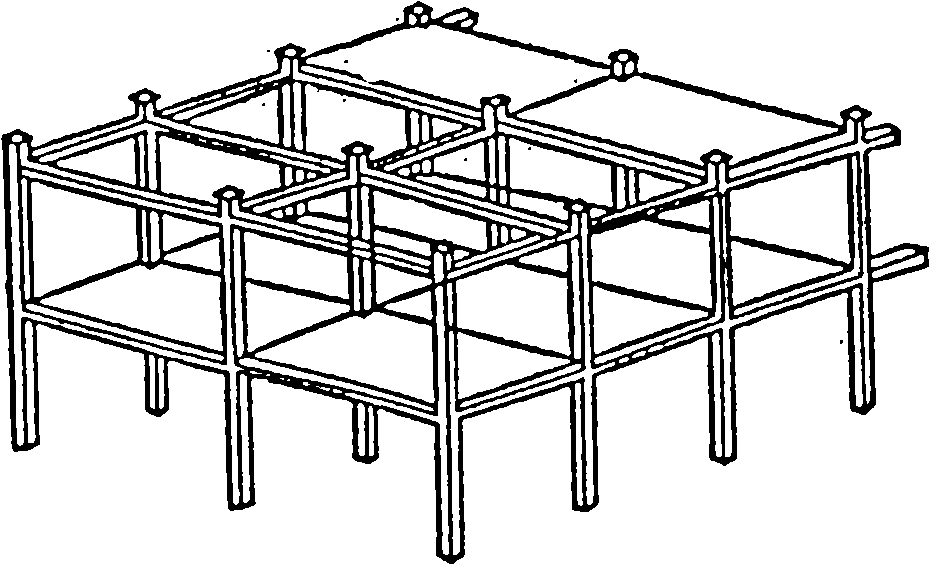

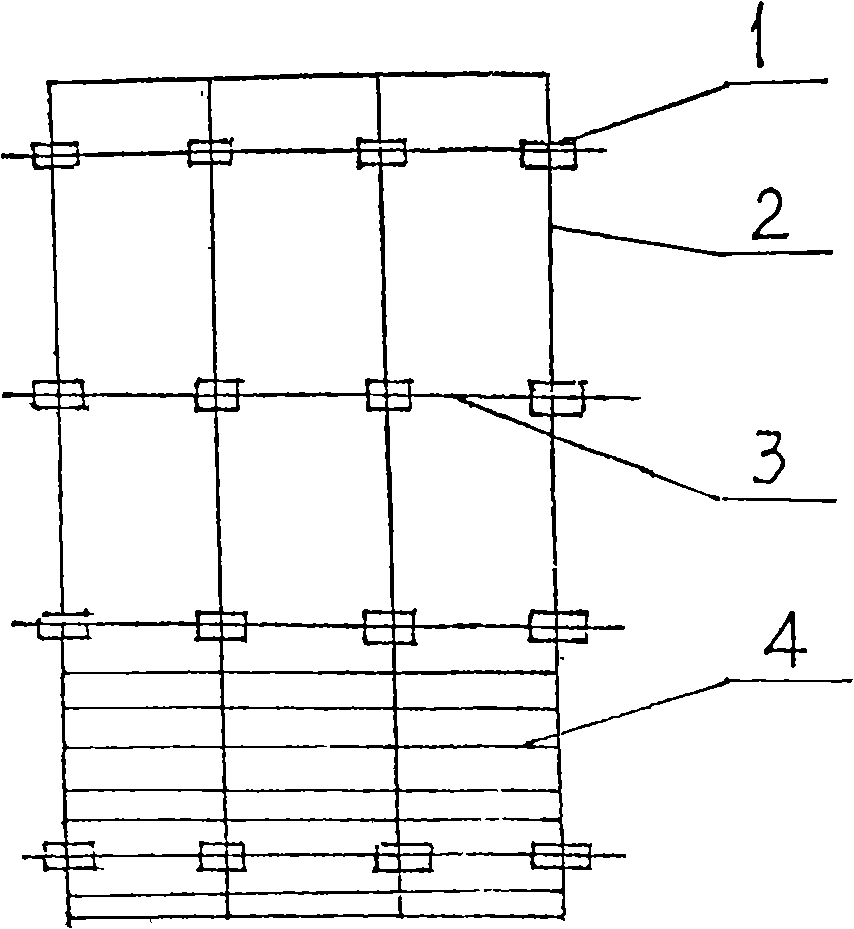

[0025] See Figure 1-Figure 7 The centrifugal cast reinforced concrete hollow rectangular column of the present invention will be mainly used as a building column in the future, but some small columns can also be used as hollow columns for weight loss. The building columns bear their own weight in the column-beam frame light wall panel house and are transmitted by the beam connection The total weight of all houses is the most important house component and can be poured by a horizontal centrifuge. The centrifuge referred to in the present invention is essentially a high-speed rotating rotating drum and its mechanical equipment. The molds for prefabricated beams and columns are installed in the rotating drum to rotate at high speed, and concrete is poured into the mould. The mould is equipped with steel bars or angle steels and channel steels. , I-beam and other steel. For mechanical equipment, please refer to the equipment of the electric pole prefabrication plant. It is similar to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com