Method for reinforcing concrete column by utilizing PVC-FRP (Poly Vinyl Chloride-Fiberglass Reinforced Plastic) pipe

A PVC-FRP, concrete column technology, applied in columns, piers, pillars, etc., can solve the problems of low utilization rate of FRP, large amount of steel, poor structural durability, etc., and achieve broad application prospects and development space, ductility and durability. Good performance, good overall performance of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

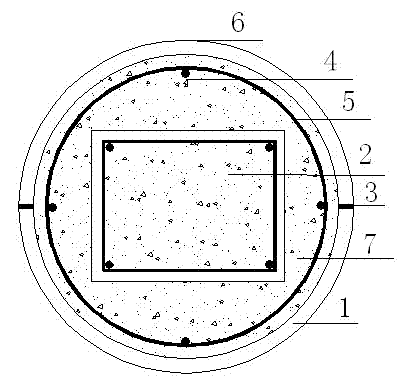

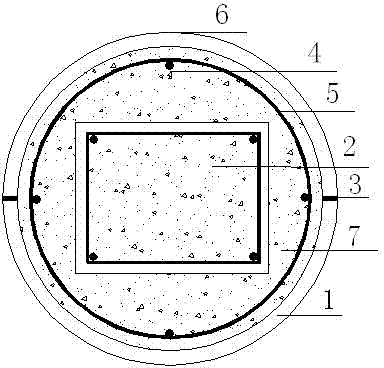

[0021] (1) Treat the original concrete column 2, remove the protective layer of the original concrete column 2, and remove the floating dust on the surface of the concrete column; in order to enhance the cohesion and integrity between the post-cast concrete and the original concrete column, ensure that they work together , the surface of the original concrete should be as rough as possible; and the strength grade of the post-cast concrete is greater than the strength grade of the original concrete column.

[0022] (2) According to the requirements of bearing capacity, calculate the amount of reinforcement required for the concrete column with reference to the relevant design codes in my country, arrange longitudinal reinforcement 4 and transverse stirrup 5 around the original concrete column 2, and bind the reinforcement cage.

[0023] (3) According to the requirements of the bearing capacity, select a PVC pipe 1 with a suitable cross-sectional size (the internal pressure of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com