Enveloping prestressing force fastening type steel tube concrete column and reinforcement method

A technology for CFST column and CFST, which is applied to columns, piers, pillars, etc., can solve problems such as difficult construction, inability to transmit shear force, no positive pressure, etc. Stress Simple Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

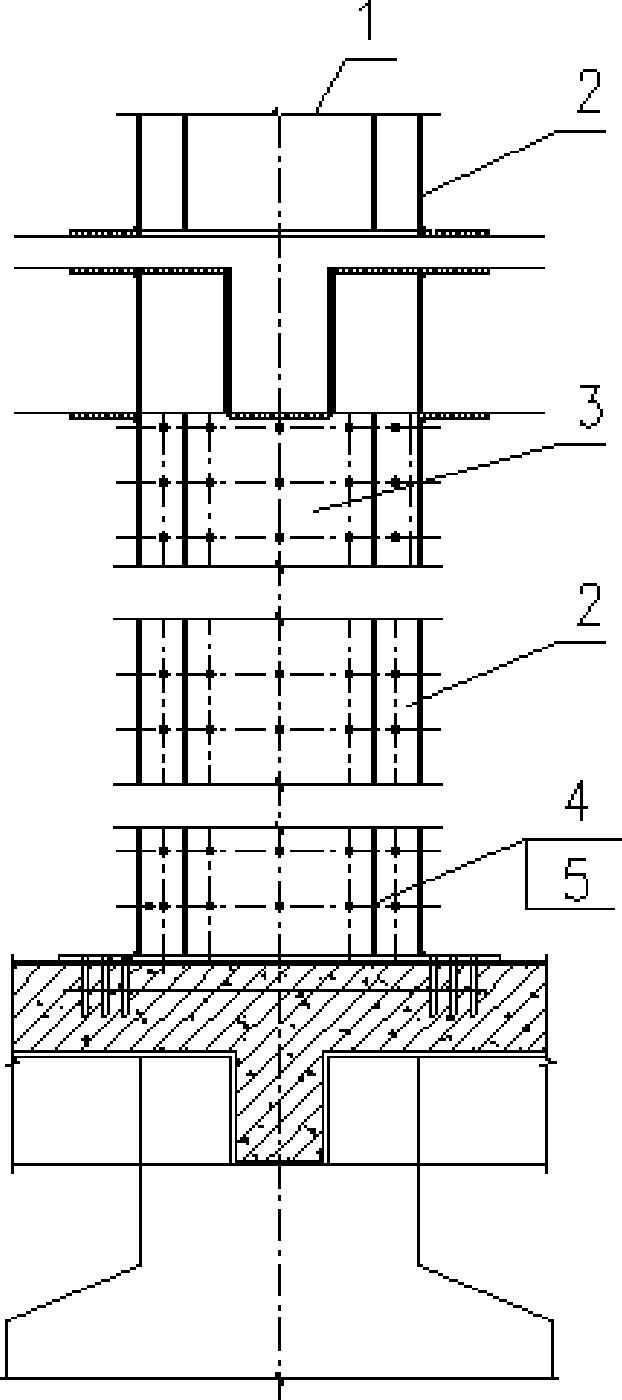

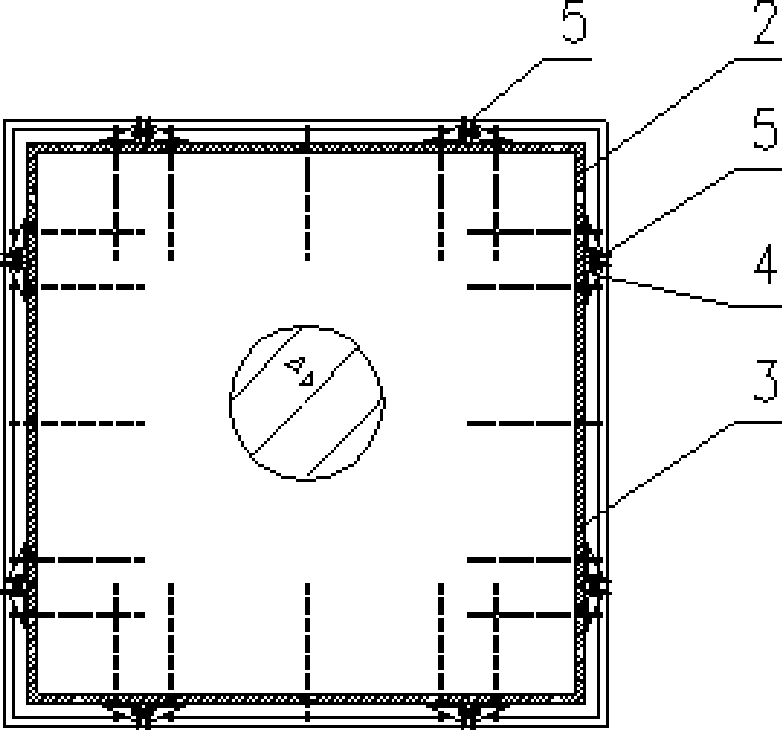

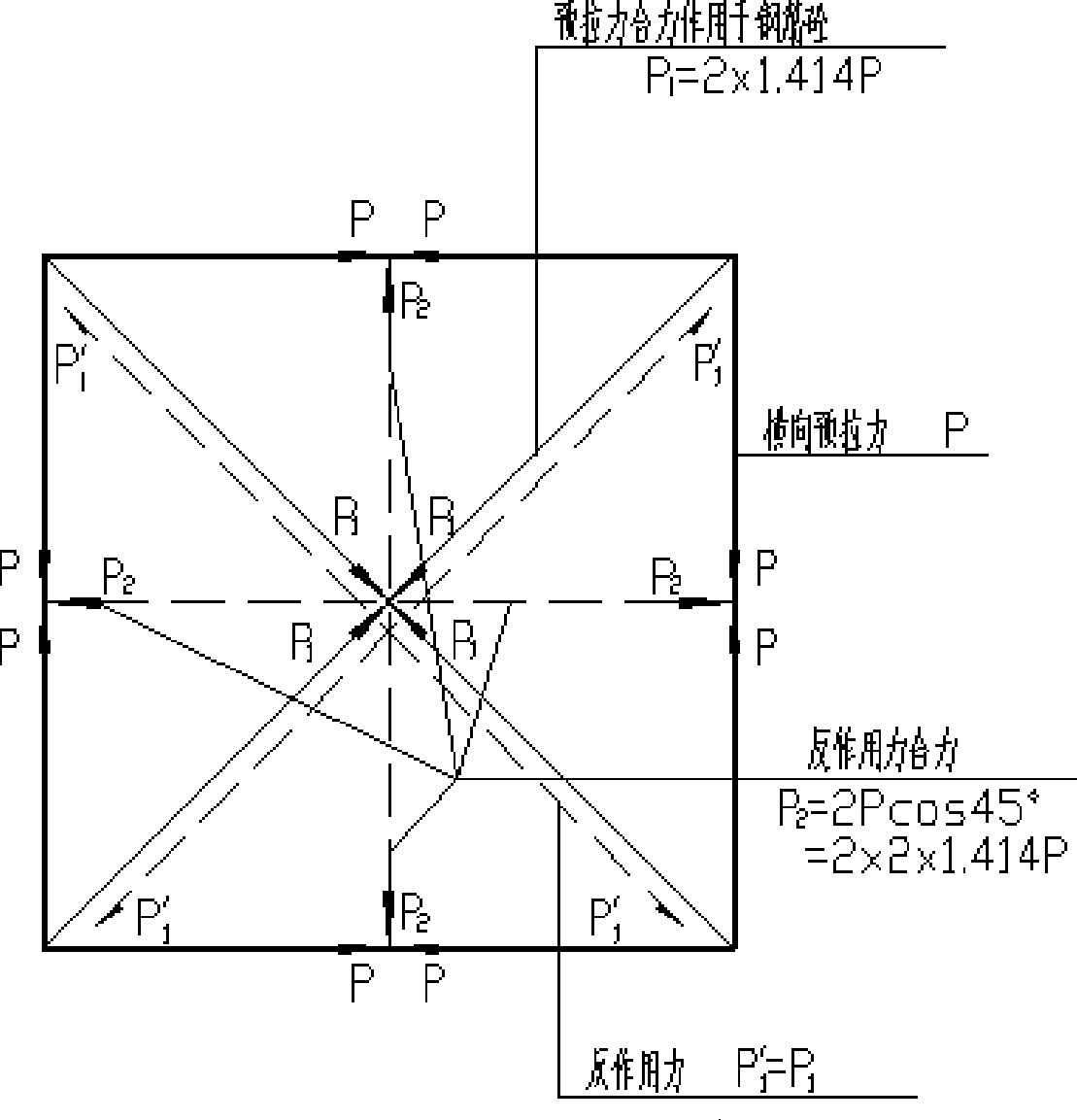

[0023] Embodiment 1 of the present invention: outsourcing prestressed fastening type steel tube concrete rectangular column. as attached figure 1 , 2 As shown, first, the outer surface of the rectangular reinforced concrete column 1 is inspected and repaired, the surface is polished, cleaned and leveled, and holes are drilled and steel bars are planted on the reinforced concrete column 1 according to the design requirements; the diameter of the implanted steel bars is 16-25mm. The implantation depth is 160-250mm, the steel bar head is exposed to the surface of the reinforced concrete column 1 by 30-40mm, and 8 fastening steel plates are respectively opened for the position of the planting bar. The hole diameter should be larger than the diameter of the planting bar to facilitate the adjustment of the position of the steel plate. 8 fastening steel plates (four angle steel plates 2 at the four corners of the reinforced concrete column 1 and four rectangular steel plates 3 in th...

Embodiment 2

[0024] Embodiment 2 of the present invention: outsourcing prestressed fastening type steel tube concrete cylinder. as attached Figure 4 , 5 As shown, firstly, the outer surface of the circular reinforced concrete column 1 is inspected and repaired, the surface is polished, cleaned and leveled; holes are drilled and steel bars are planted on the reinforced concrete column 1 according to the design requirements; the diameter of the implanted steel bars is 16-25mm , the implantation depth is 160-250mm, the steel head is exposed to the surface of the reinforced concrete column 1 by 30-40mm, and 4 pieces (D≤800mm) or 8 pieces (D>800mm) of arc-shaped cross-section steel plates 6 are provided for the position of the reinforcement respectively. (the steel plate 6 of arc-shaped section is 1 / 4 arc-shaped or 1 / 8 arc-shaped section) perforate, aperture should be greater than planting bar diameter, in order to adjust the position of steel plate. 4 or 8 arc-shaped cross-section steel pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com