Method and structure for reinforcing concrete post using angle steel

A technology for reinforced concrete columns and concrete columns, applied in the directions of columns, pier columns, pillars, etc., can solve the problem of the angle steel and the concrete column not being tightly attached, and achieve the effect of reducing costs and improving strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the invention:

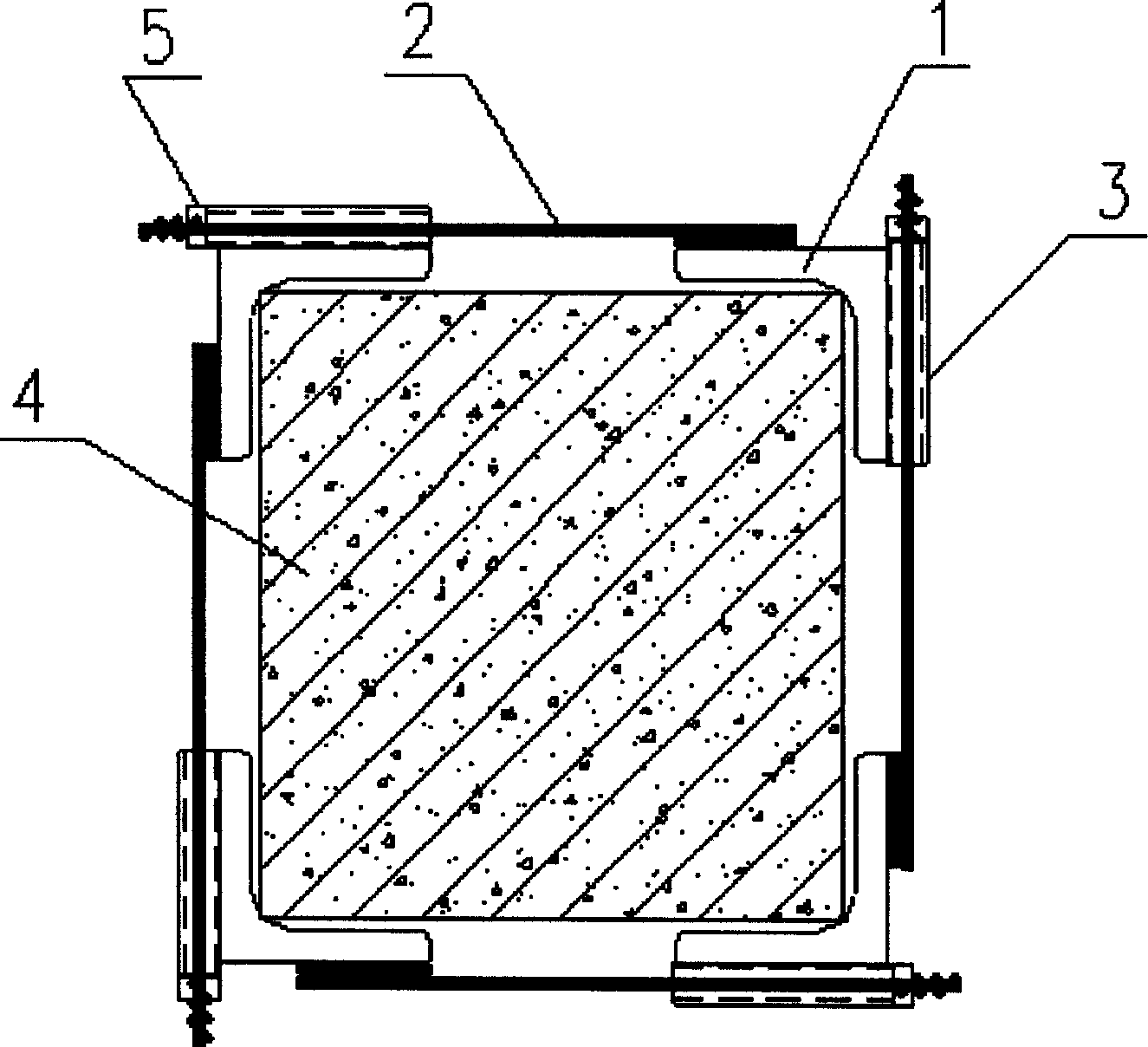

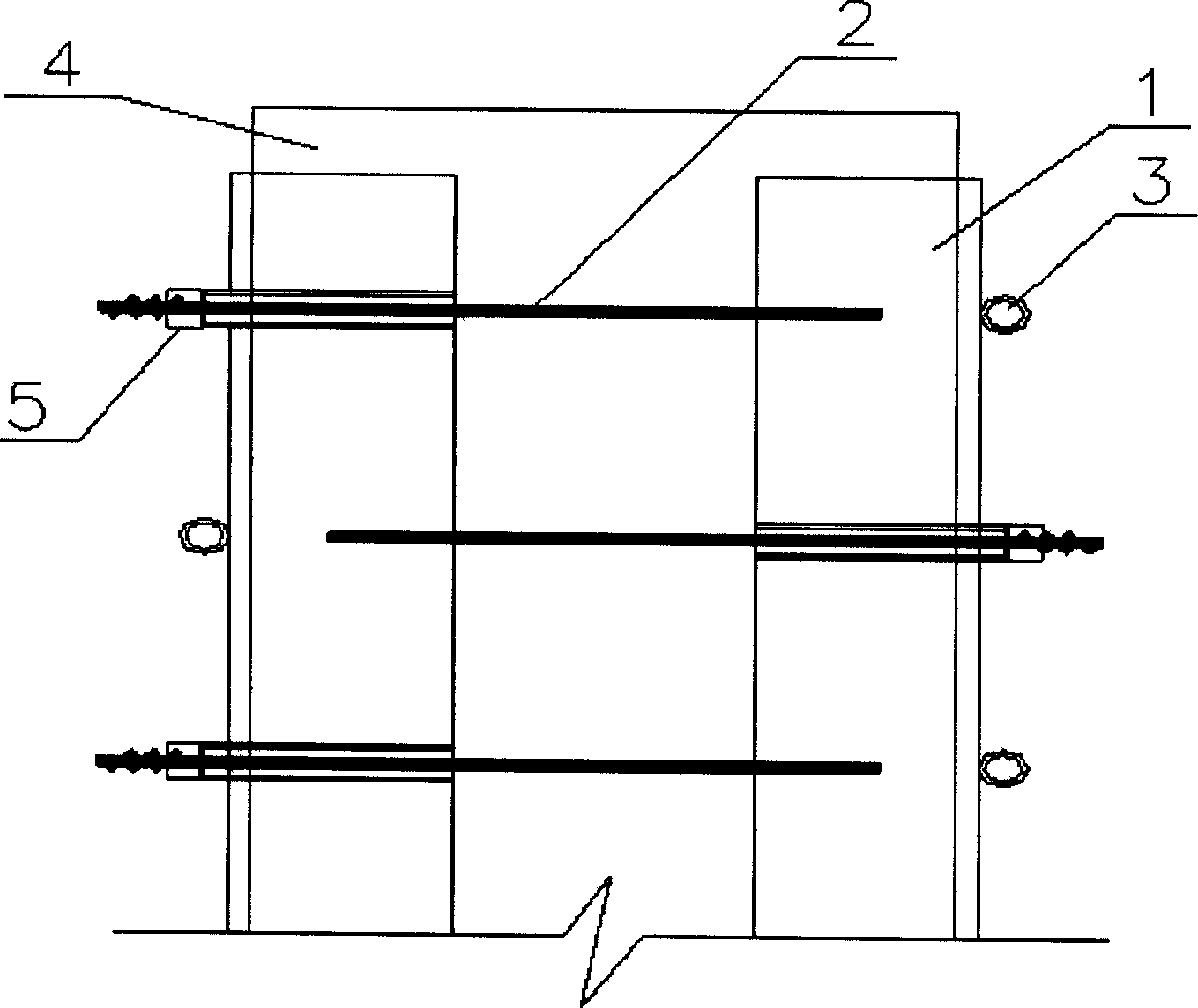

[0015] First, according to the geometric parameters of the reinforced concrete column 4 and the strength requirements of the load, the specifications and lengths of the angle steel 1, the steel bolt 2, the steel pipe 3 and the nut 5 are designed and determined, and the layout and distance of the upper and lower adjacent steel hoops are determined. On each leg of the angle steel 1, reinforcement bolts 2 and steel pipes 3 are arranged at intervals, so as to form vertically adjacent reinforcement hoops in a staggered arrangement.

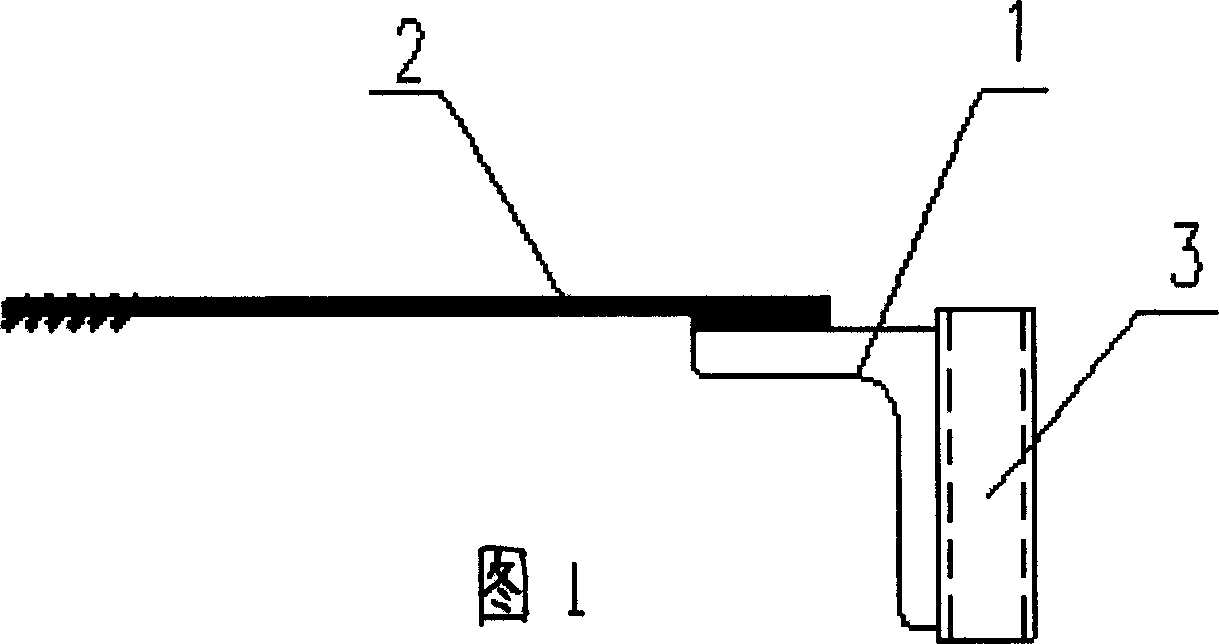

[0016] Secondly, make the angle steel assembly, that is, weld the reinforcement bolt 2 on the outer surface of one limb of the angle steel 1, and weld the steel pipe 3 on the outer surface of the other limb, so that the arrangement of the reinforcement bolt 2 and the steel pipe 3 in the length direction of the angle steel 1 is arranged at intervals, That is, the order of arrangement on one limb of the angle steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com