Connecting structure and method for prefabricated reinforced concrete beam and prefabricated reinforced concrete column

A technology for reinforced concrete columns and reinforced concrete beams, which is applied to truss structures, columns, joists, etc., can solve the problems of long construction period, damage, and complicated construction procedures, so as to simplify installation procedures, ensure construction quality, and shorten construction. The effect of the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

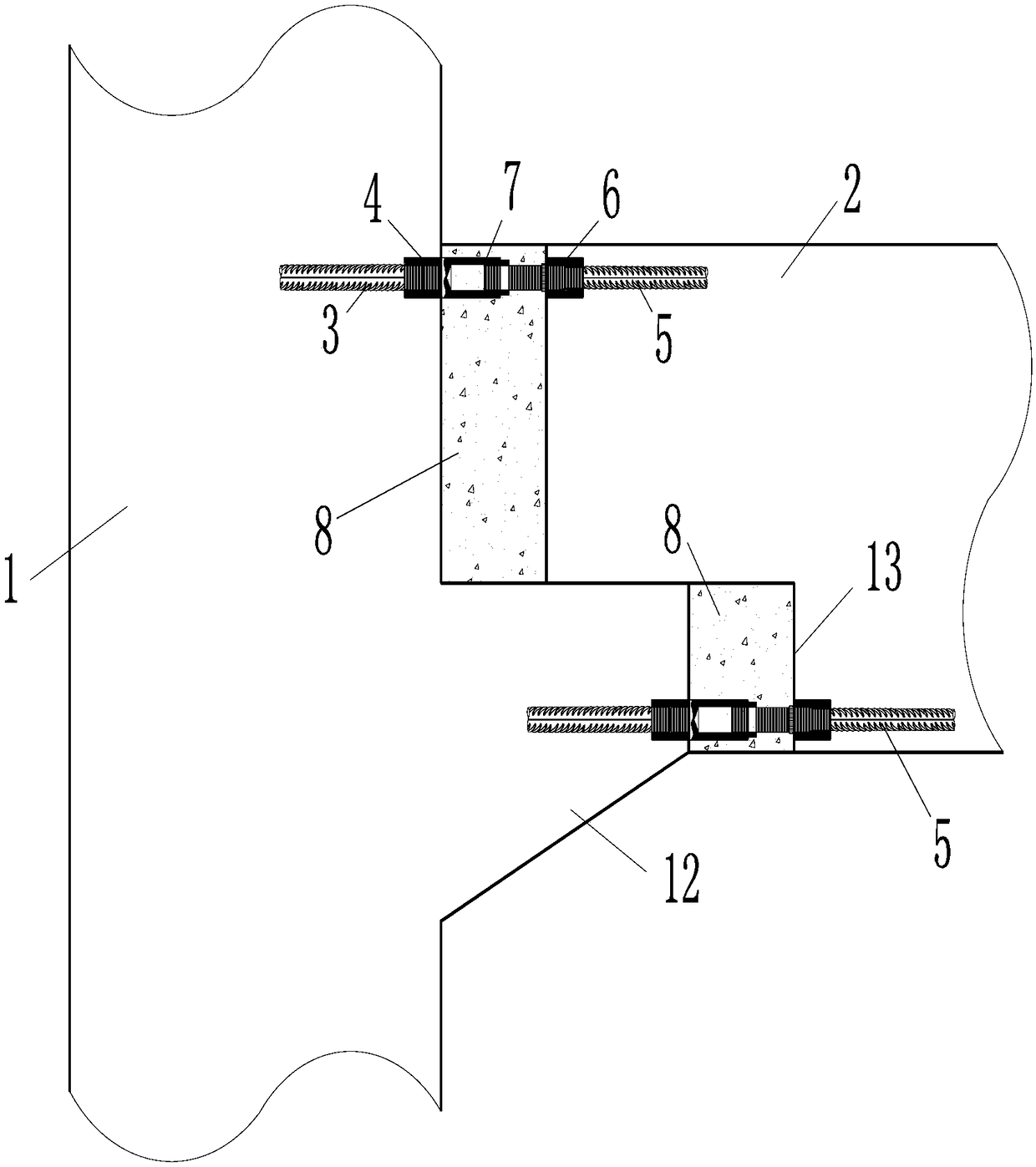

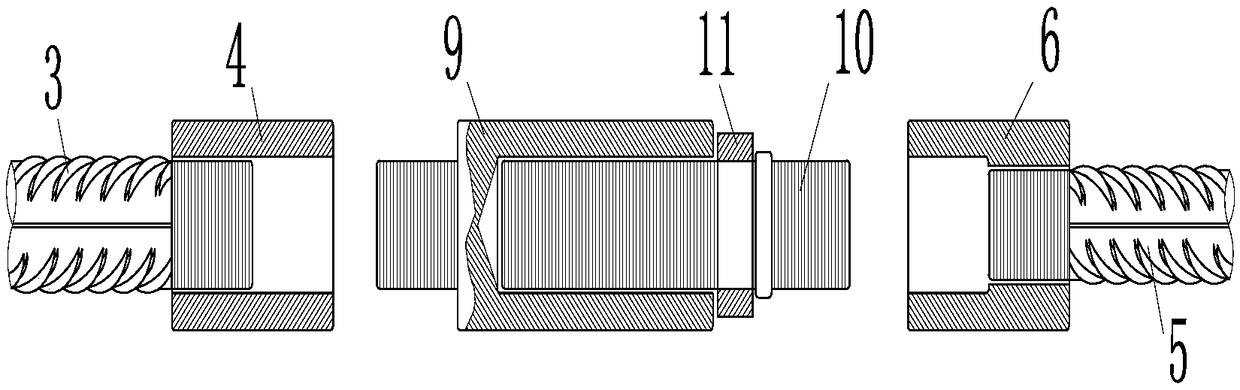

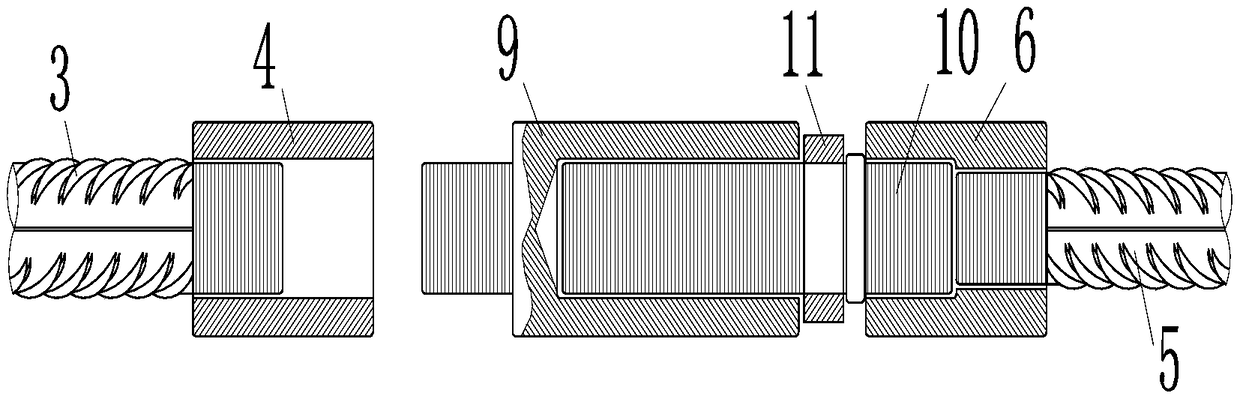

[0024] like figure 1 As shown, the connection structure of prefabricated reinforced concrete beams and columns provided by the present invention is mainly composed of prefabricated reinforced concrete columns 1, prefabricated reinforced concrete beams 2, pre-embedded anchor bars 3, straight thread standard sleeves 4, beam inner longitudinal reinforcements 5, straight Composed of positive and negative threads with different diameter sleeves 6, adjustable connectors 7 and secondary grouting material connection section 8; pre-embedded anchor bars 3 are connected with straight thread standard sleeves 4 and embedded in prefabricated reinforced concrete columns together 1, the longitudinal reinforcement 5 in the beam is connected with the straight thread positive and negative wire different diameter sleeve 6 and is embedded in the reinforced concrete beam 2 together; the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com