Welding device for ball type welding flux

A welding device and soldering technology, which is applied in the direction of welding equipment, auxiliary devices, tin feeding devices, etc., can solve the problems of short heating time, insufficient solder melting, inconvenient maintenance and debugging, etc., so as to prevent the decline of welding quality and avoid the deviation of solder amount , to avoid the effect of replacement debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

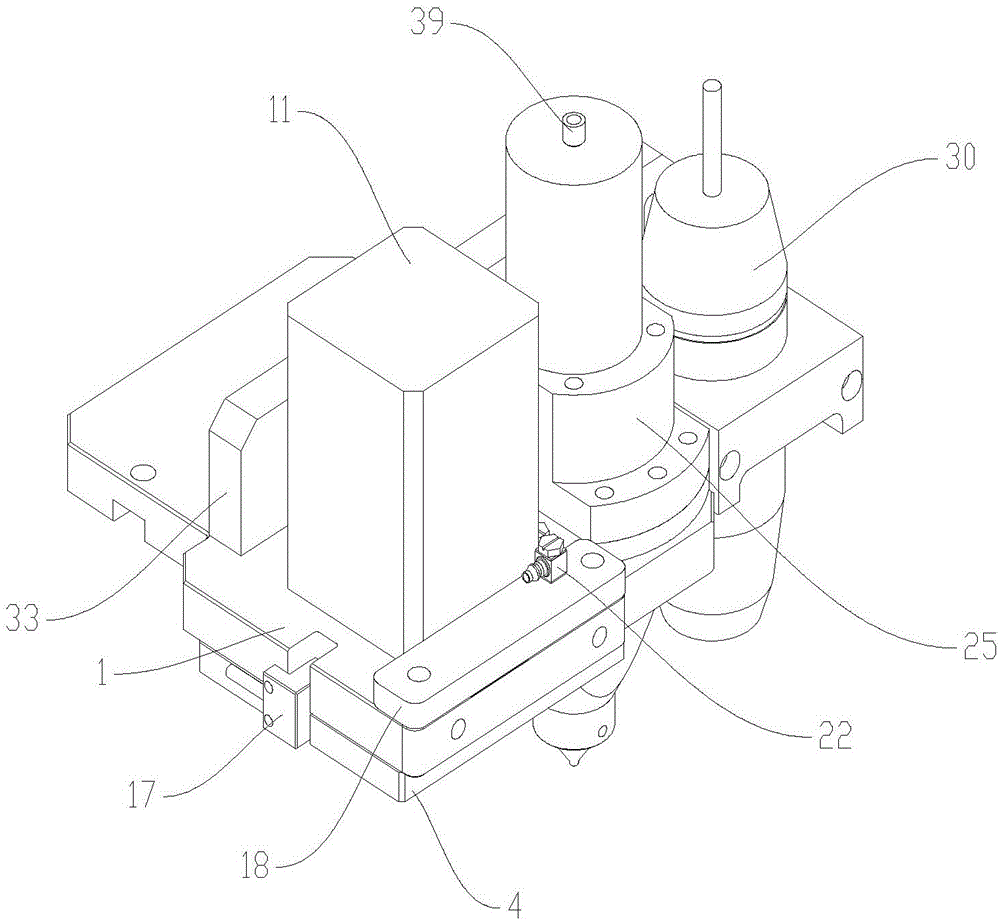

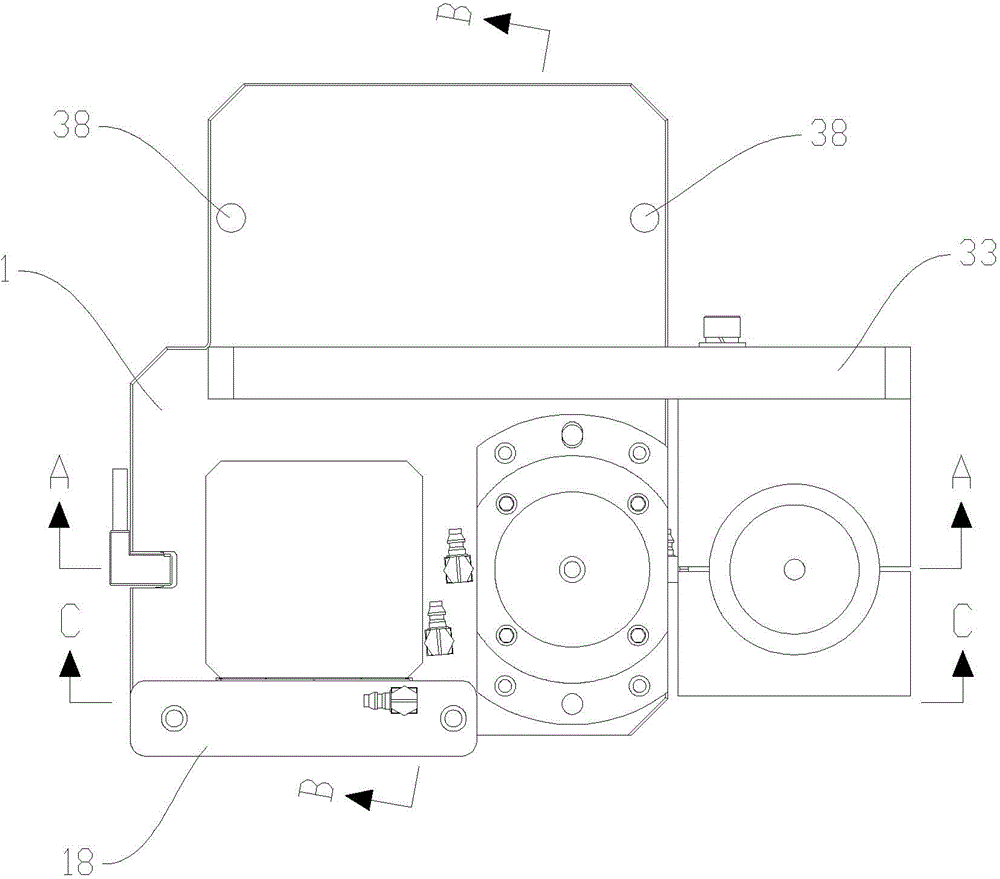

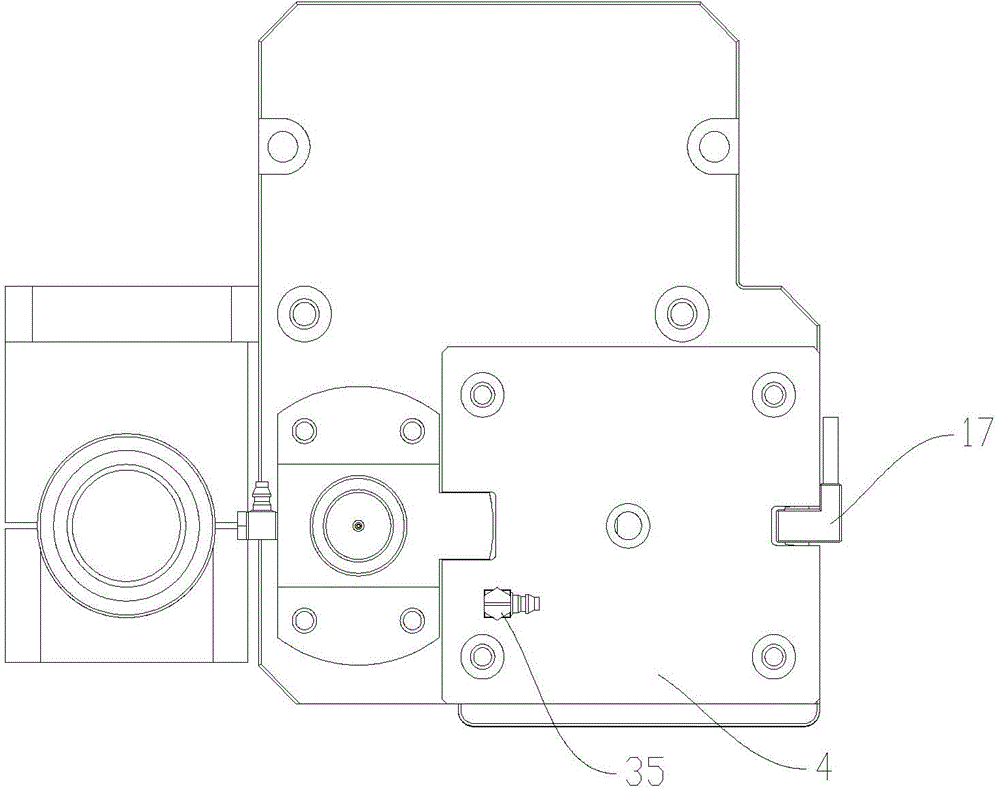

[0065] The embodiment of the present invention discloses a welding device for ball solder. The welding device for ball solder includes: a silo part, a transmission part, a solder detection part, a welding part and a bottom plate; wherein the silo part is used for storing balls Solder; the transmission part is connected with the silo part, and is used to take ball solder from the silo part and transmit it to the solder detection part and the welding part; the solder detection part is used to detect whether there is ball solder transmitted by the transmission part; the welding part is used to receive The transfer section transfers ball-like solder and performs soldering operations.

[0066] figure 1 It is a structural schematic diagram of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com