Soldering preparation method for stainless steel laminate type inspirator

A stainless steel layer and injector technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of plastic deformation of the circulation channel, and reduce the possibility of plastic deformation and the possibility of plastic deformation of the circulation channel. the effect of short welding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

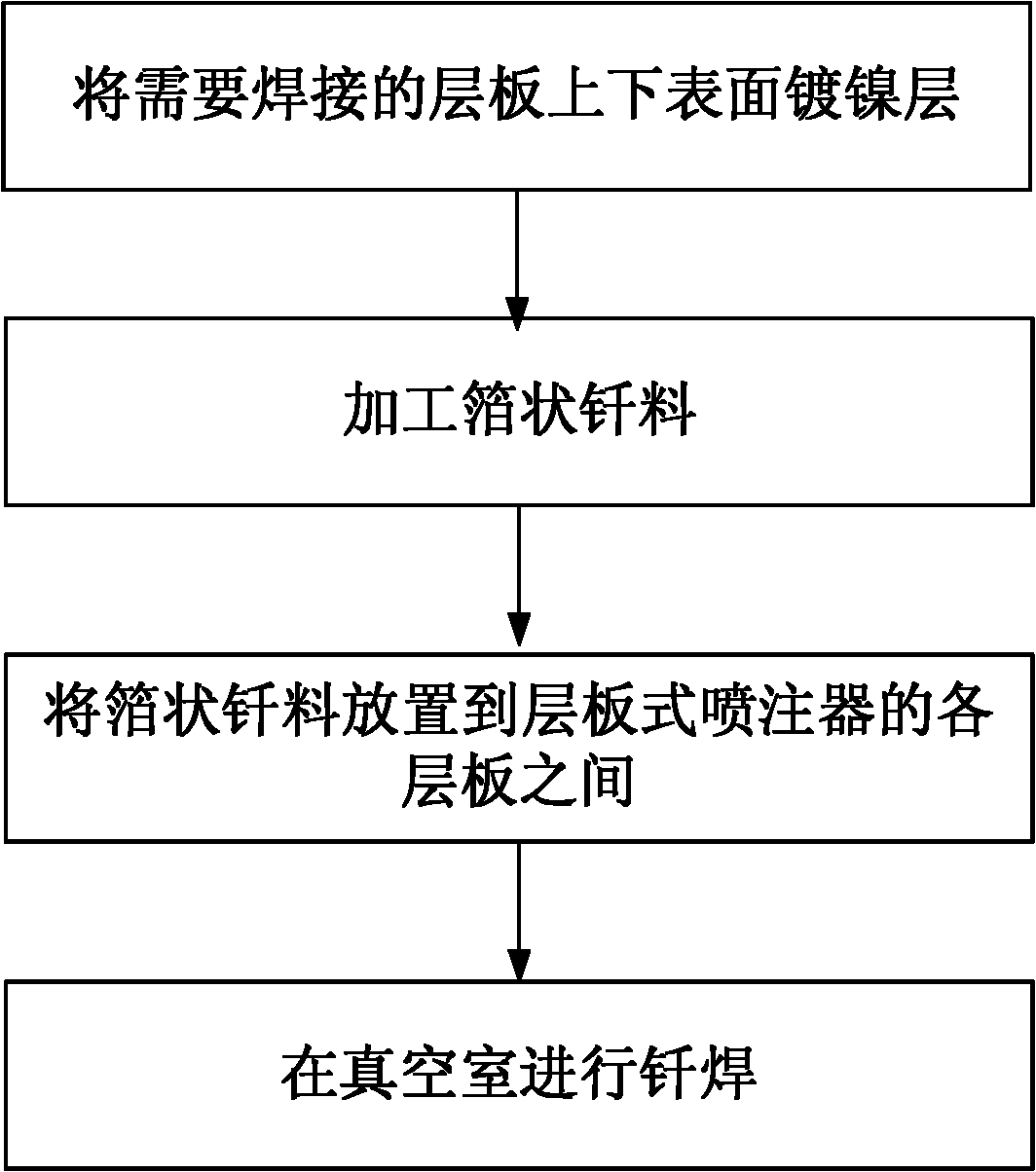

[0037] A brazing preparation method of a stainless steel laminate injector provided by the invention, such as figure 1 As shown, it specifically includes the following steps:

[0038] Step 1: Plating a nickel layer of 0.01 to 0.02 mm on the upper and lower surfaces of the laminates to be welded for each layer of the laminate injector to be brazed, respectively, using an electroplating process.

[0039] Step 2: Process the 0.03-0.06mm thick foil-shaped solder according to the shape between the two adjacent layers in the laminate injector to obtain n-1 layers of foil-shaped solder, where n is to be brazed The number of layers of the laminate structure of the laminate injector. The composition of the foil-shaped brazing filler metal is as follows: 20-30% copper, 0.1-5% manganese, 0.1-3% nickel, and the rest is silver.

[0040] Step 3: Place n-1 pieces of foil-shaped solder between the n laminate parts of the laminate injector, and assemble the laminate injector according to the...

Embodiment 1

[0050] Example 1: Brazing stainless steel laminate injector with Ag-20Cu-0.1Mn-0.1Ni solder

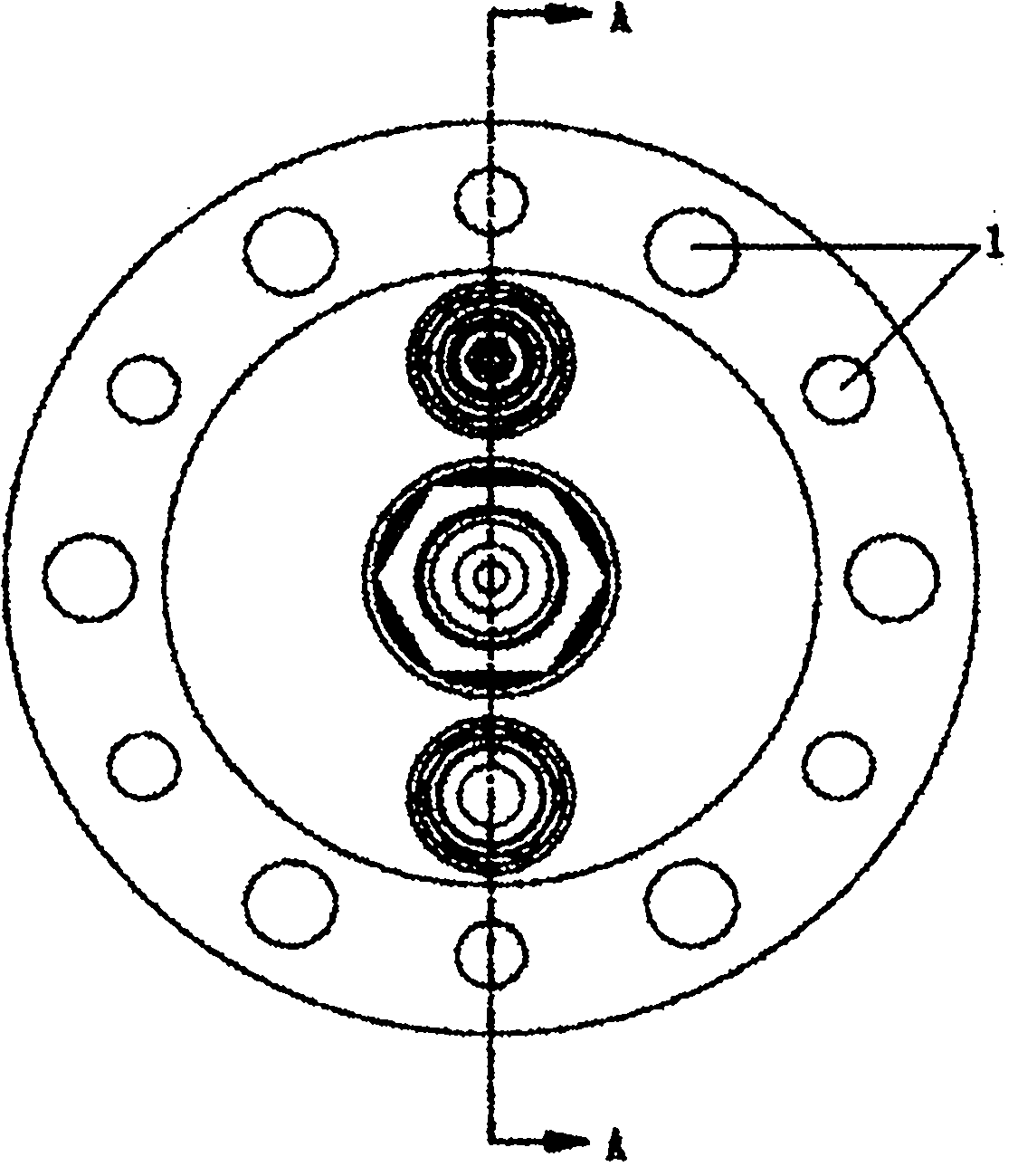

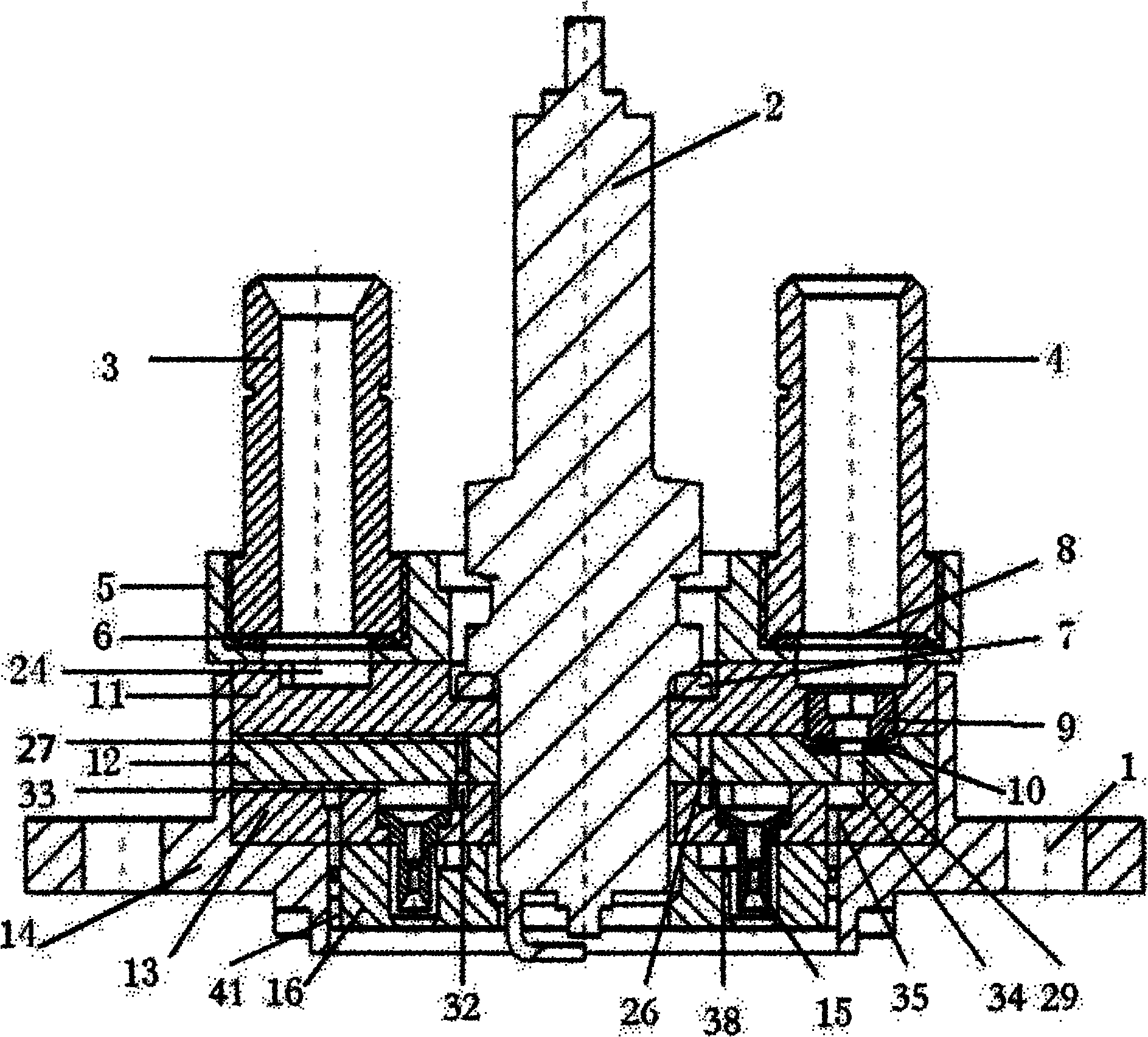

[0051] When applying the brazing preparation method of the stainless steel laminate injector provided by the invention to the brazing preparation of the gas-oxygen / methane small-thrust engine laminate injector (having a five-layer laminate structure), it specifically includes the following steps :

[0052] Step 1: For the fuel plate, oxidant plate, top plate, splitter plate A and splitter plate B of the gas-oxygen / methane small-thrust engine laminate injector, the surfaces to be welded are plated with a nickel layer of 0.01mm on the surface by electroplating.

[0053] Step 2: Process the 0.03mm thick foil-shaped brazing filler metal according to the shape between the top layer plate, splitter plate A, splitter plate B, fuel plate and oxidizer plate of the laminate injector, and obtain 4 Block foil solder. The composition of the foil-like solder is as follows: 20% copper, 0.1% mang...

Embodiment 2

[0057] Example 2: Using Ag-28Cu-0.1Mn-0.1Ni brazing material to braze the stainless steel laminate injector

[0058] When applying the brazing preparation method of the stainless steel laminate injector provided by the present invention to brazing the oxygen / methane small-thrust engine laminate injector (having a five-layer laminate structure), it specifically includes the following steps :

[0059] Step 1: Plating a nickel layer of 0.02 mm on the surfaces of the five stainless steel laminates to be welded by electroplating.

[0060] Step 2: Process the 0.03mm foil-shaped solder into the desired pattern according to the assembled position to obtain four layers of foil-shaped solder. The composition of the foil-shaped solder is 28% copper and 0.1% copper by weight. Manganese, 0.1% nickel, the remainder silver;

[0061] Step 3: Place the foil-like solder between the fuel plate, oxidant plate, top plate, splitter plate A and splitter plate B of the gas-oxygen / methane small-th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com