Aluminum powder-containing flux-cored silver brazing filler metal for brazing hard alloy and preparation method

A technology of hard alloy and silver solder, which is applied in the direction of welding/cutting medium/material, welding equipment, welding medium, etc., can solve the problems of affecting production and manufacturing efficiency, short service life, non-wear-resistant brazing seam, etc., and achieve improvement Wetting and spreading properties, suppression of high temperature turbulent flow, and effect of lowering brazing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

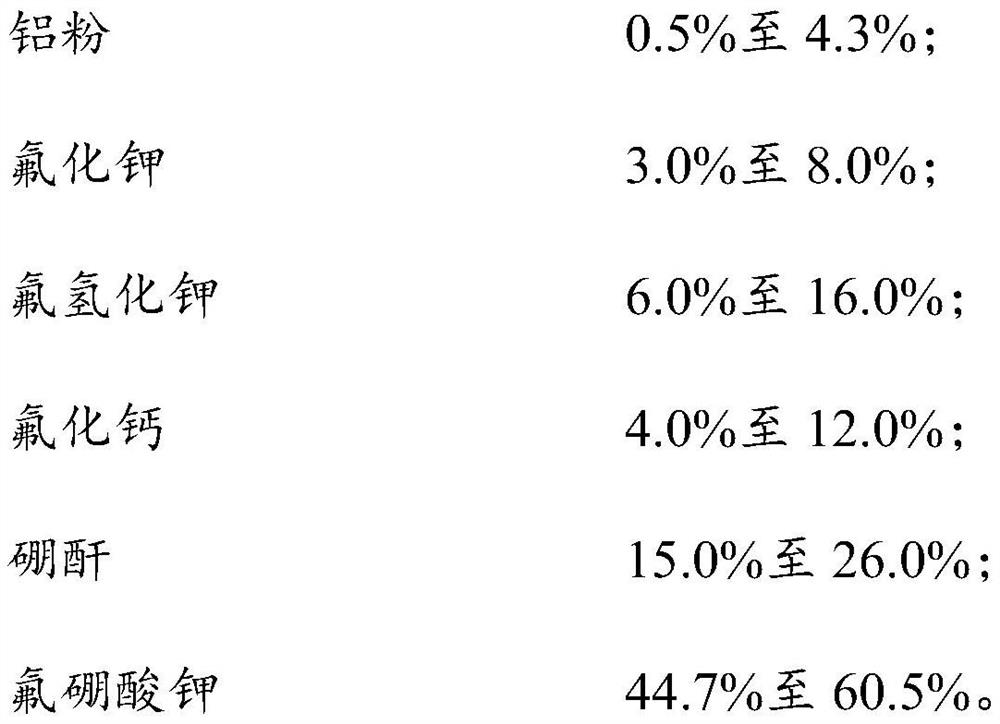

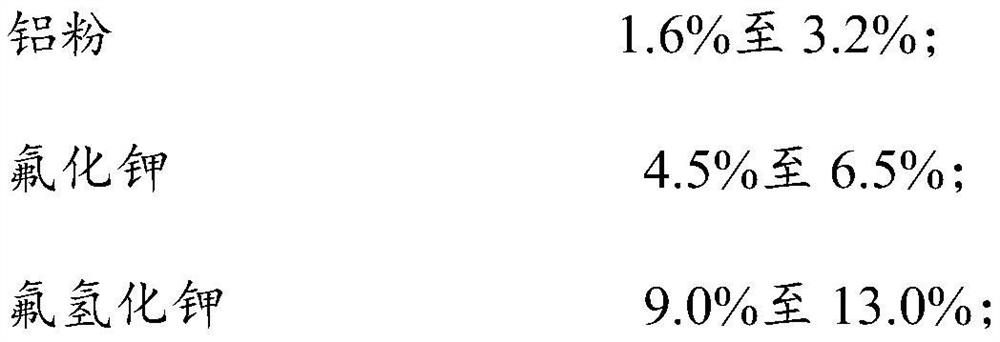

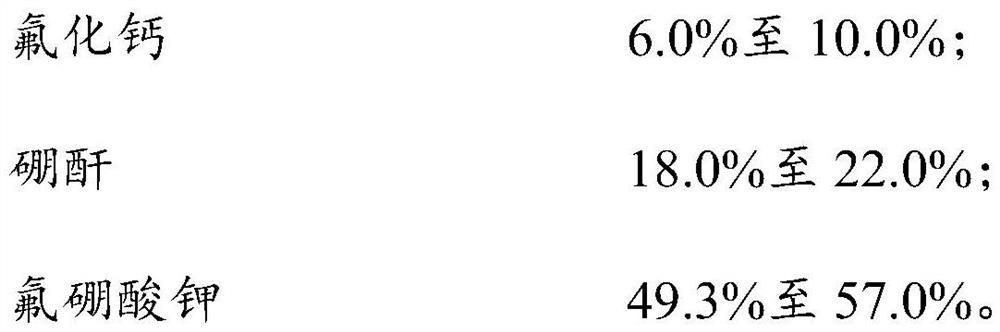

[0031]This example discloses a brazing metal-containing powder silver solder and preparation method for brazing hard alloy, including 20% of the flux dielectric core and 80% silver-containing metal layer that accounted for the total mass of the silver brazing material. The aluminum powder is filled in the metal wrapped inside, and the mass ratio of the flux powder in the present embodiment is shown in Table 1. The particle size of the aluminum powder is 240 nm to 400 nm, and there is no agglomeration before the mixing;

[0032]The silver-containing metal layer is wrapped as a pharmaceutical core solder, which includes the following substances: AG18.0%, Cu46.0%, Sn 2.1%, and the margin is Zn.

[0033]Table 1 Examples 1 to 3 made of flux dielectric core components and dosage

[0034]

[0035]In this example, the production method of the drug core silver brazing material includes the following steps:

[0036]The silver metal layer raw material is melted and secondary refinery according to the conve...

Embodiment 2

[0043]This example is shown in Table 1 as described in the main differences of the first embodiment.

Embodiment 3

[0045]This example is shown in Table 1 as described in the main differences of the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com