A kind of high-voltage ceramic pulse capacitor, dielectric material and preparation method thereof

A technology of pulse capacitors and dielectric materials, applied in the direction of fixed capacitor dielectrics, capacitors, fixed capacitors, etc., can solve the problems of high spontaneous polarization, complex crystal phase structure, and low breakdown strength, so as to improve density and insulation Effect of resistivity and loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

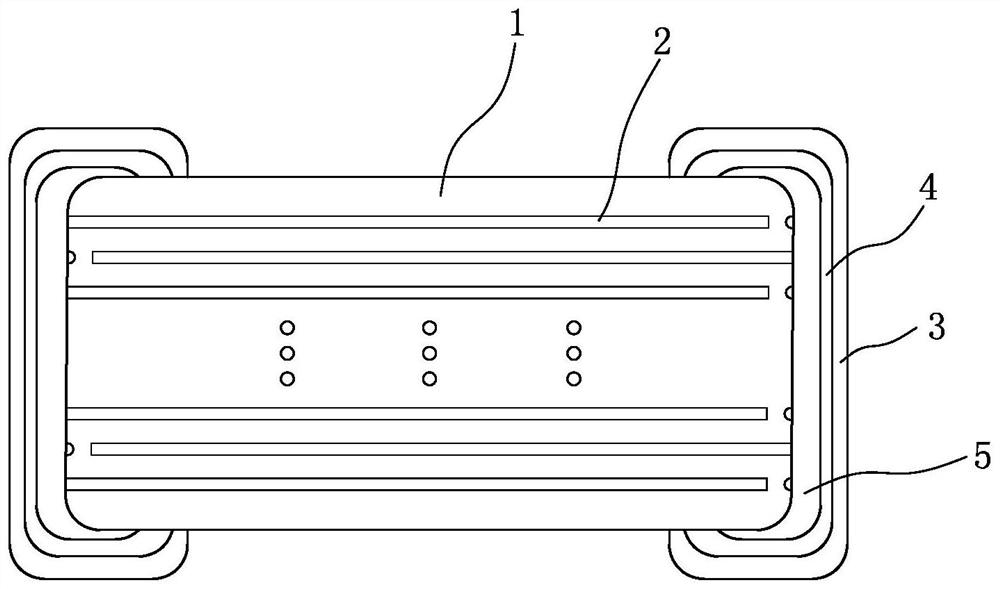

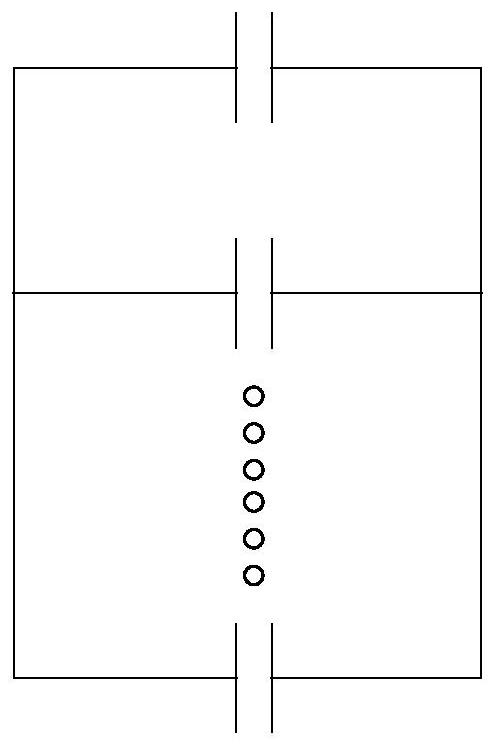

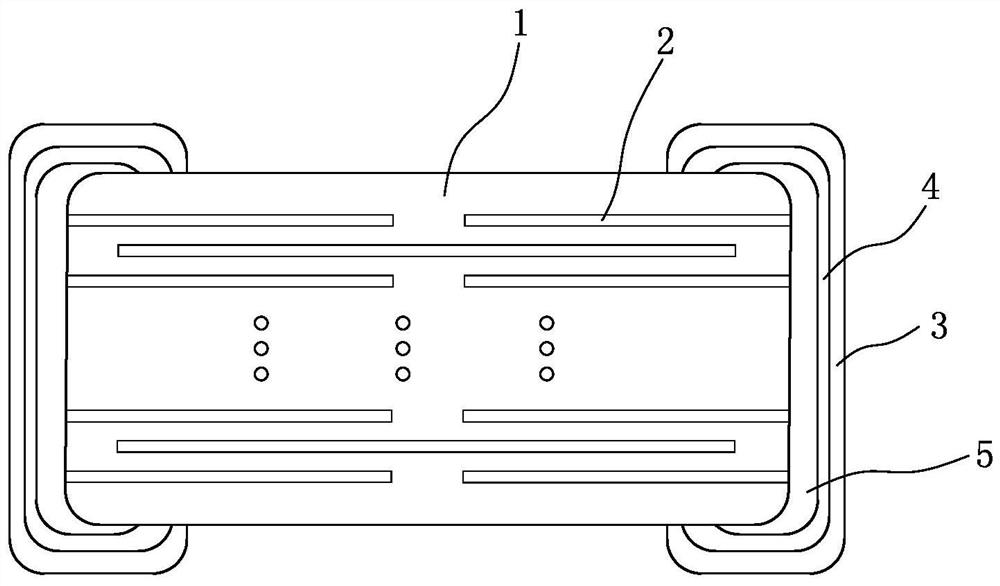

Image

Examples

Embodiment 1

[0049] A method for manufacturing a high-voltage ceramic pulse capacitor, comprising the following steps:

[0050] Step 1, according to the molar ratio of 1:1, weigh 64.88 parts by weight of SrCO 3 , 35.12 parts by weight TiO 2 , mixed by ball milling, dried, crushed through a 40-mesh sieve, and calcined at 1150°C for 2 hours to synthesize SrTiO 3 ;

[0051] Step 2, according to the molar ratio of 1:1, weigh 54.51 parts by weight of SrCO 3 , 45.49 parts by weight ZrO 2 , mixed by ball milling, dried, crushed through a 40-mesh sieve, and calcined at 1200°C for 2 hours to synthesize SrZrO 3 ;

[0052] Step 3, weigh 73.04 parts by weight of ZnO and 26.96 parts by weight of SiO in a molar ratio of 2:1 2 , mixed by ball milling, dried, crushed through a 40-mesh sieve, and calcined at 900°C for 2 hours to synthesize Zn 2 SiO 4 ;

[0053] Step 4, according to the molar ratio of 1:2, weigh 74.46 parts by weight of Bi 2 o 3 , 25.54 parts by weight TiO 2 , mixed by ball mill...

Embodiment 2

[0057] Step 1, according to the molar ratio of 0.99:1, weigh 64.65 parts by weight of SrCO 3 , 35.35 parts by weight TiO 2 , mixed by ball milling, dried, crushed through a 40-mesh sieve, and calcined at 1200°C for 1 hour to synthesize SrTiO 3 ;

[0058] Step 2, according to the molar ratio of 1.01:1, weigh 54.75 parts by weight of SrCO 3 , 45.25 parts by weight ZrO 2 , mixed by ball milling, dried, crushed through a 40-mesh sieve, and calcined at 1050°C for 3 hours to synthesize SrZrO 3 ;

[0059] Step 3, weigh 73.14 parts by weight of ZnO and 26.86 parts by weight of SiO in a molar ratio of 2.01:1 2 , mixed by ball milling, dried, crushed through a 40-mesh sieve, and calcined at 1000°C for 1 hour to synthesize Zn 2 SiO 4 ;

[0060] Step 4, according to the molar ratio of 1:3, weigh 66.03 parts by weight of Bi 2 o 3 , 33.97 parts by weight TiO 2 , mixed by ball milling, dried, crushed through a 40-mesh sieve, and calcined at 1000°C for 1 hour to synthesize Bi 2 Ti...

Embodiment 3

[0064] Step 1, according to the molar ratio of 1.02:1, weigh 65.33 parts by weight of SrCO 3 , 34.67 parts by weight TiO 2 , mixed by ball milling, dried, crushed through a 40-mesh sieve, and calcined at 1150°C for 2 hours to synthesize SrTiO 3 ;

[0065] Step 2, weigh 54.00 parts by weight of SrCO at a molar ratio of 0.98:1 3 , 46.00 parts by weight ZrO 2 , mixed by ball milling, dried, crushed through a 40-mesh sieve, and calcined at 1200°C for 2 hours to synthesize SrZrO 3 ;

[0066] Step 3, weigh 73.04 parts by weight of ZnO and 26.96 parts by weight of SiO in a molar ratio of 2:1 2 , mixed by ball milling, dried, crushed through a 40-mesh sieve, and calcined at 900°C for 2 hours to synthesize Zn 2 SiO 4 ;

[0067] Step 4, according to the molar ratio of 1:1, weigh 85.36 parts by weight of Bi 2 o 3 , 14.64 parts by weight TiO 2 , mixed by ball milling, dried, crushed through a 40-mesh sieve, and calcined at 900°C for 2 hours to synthesize Bi 2 TiO 5 ;

[0068...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com