Welding machine output characteristic control method

A technology of output characteristics and control methods, applied in the direction of digital control, adaptive control, general control system, etc., can solve the problems that the external characteristics of the welding machine are easily affected by the performance of the device, and the consistency is not good, so as to enrich the external interface and communication ability, improved service life and range of use, and short development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

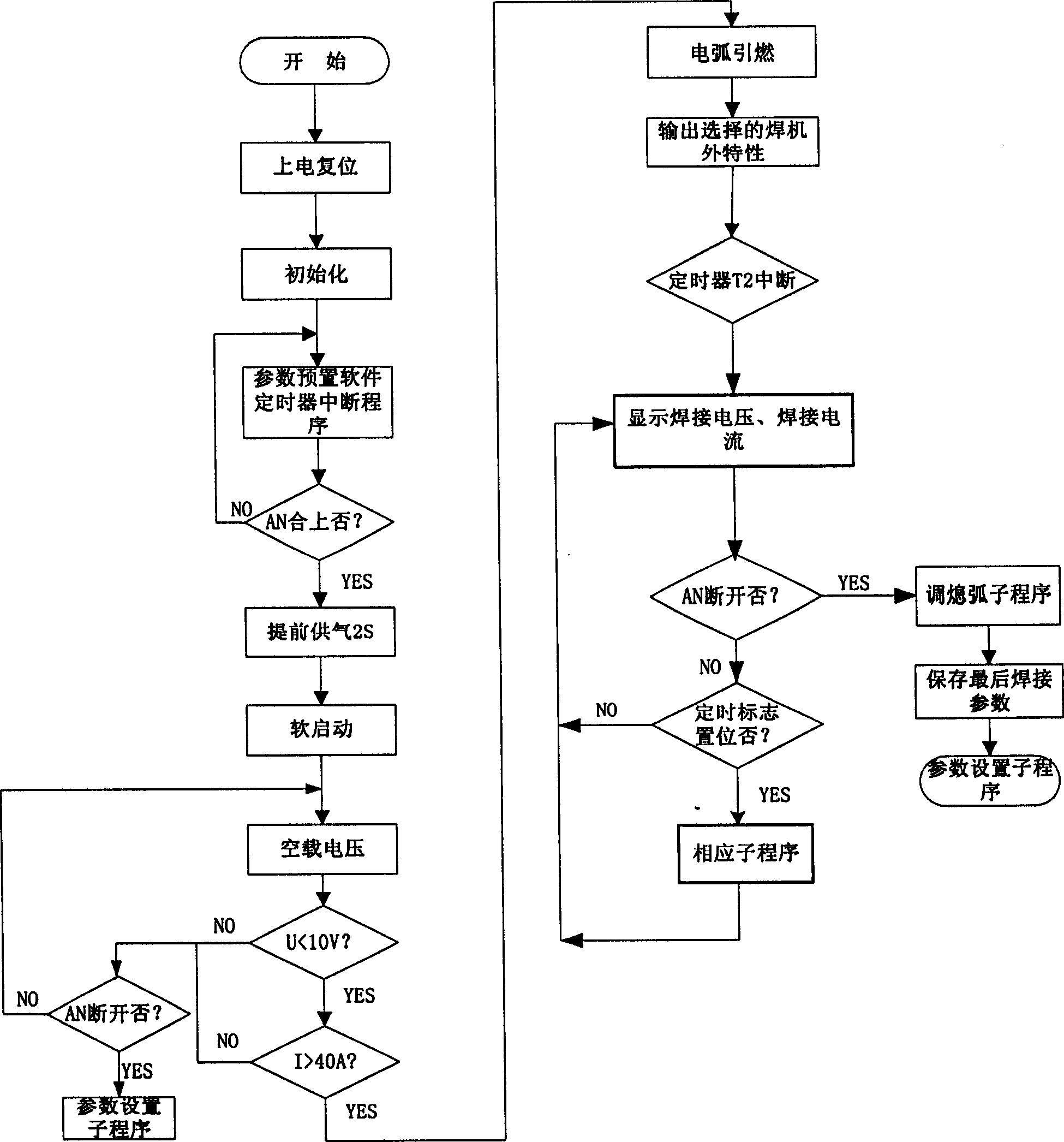

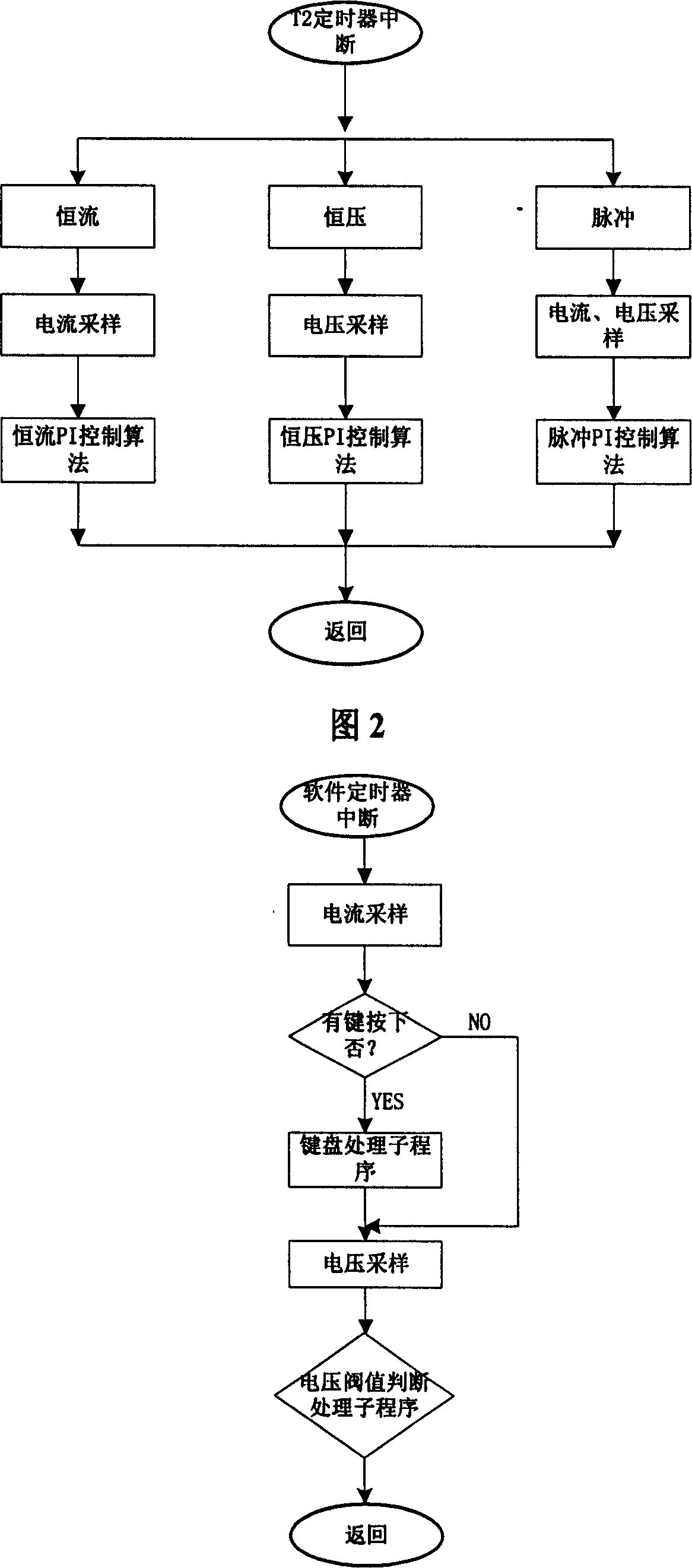

[0019] The output characteristic control method of welding machine of the present invention comprises the steps:

[0020] 1. Pre-select the corresponding welding method and preset the corresponding parameters;

[0021] 2. Determine whether the welding machine starts;

[0022] 3. Whether the arc is ignited;

[0023] 4. Judging whether the welding process is stable, that is, whether it is consistent with the preset parameters, and adaptively adjusts the output of the welding machine according to the specific welding process to obtain the required output characteristics;

[0024] 5. Judging the state of the welding torch switch (AN) and combining the welding method to judge whether the arc is extinguished, otherwise

[0025] Repeat steps 4 to 5.

[0026] The method of the present invention is further illustrated below in conjunction with the specific workflow:

[0027] like figure 1 Shown: the present invention specifically comprises the steps:

[0028] Step 1. Power on and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com