Steel column provided with thick plates, special-shaped skew bracket and truss layer and manufacturing method of steel column

A production method and technology of corbels, which are applied to columns, piers, pillars, etc., can solve the problems of difficult processing and production of box-shaped steel columns, and achieve the effects of solving factory production, improving processing speed and ensuring assembly accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

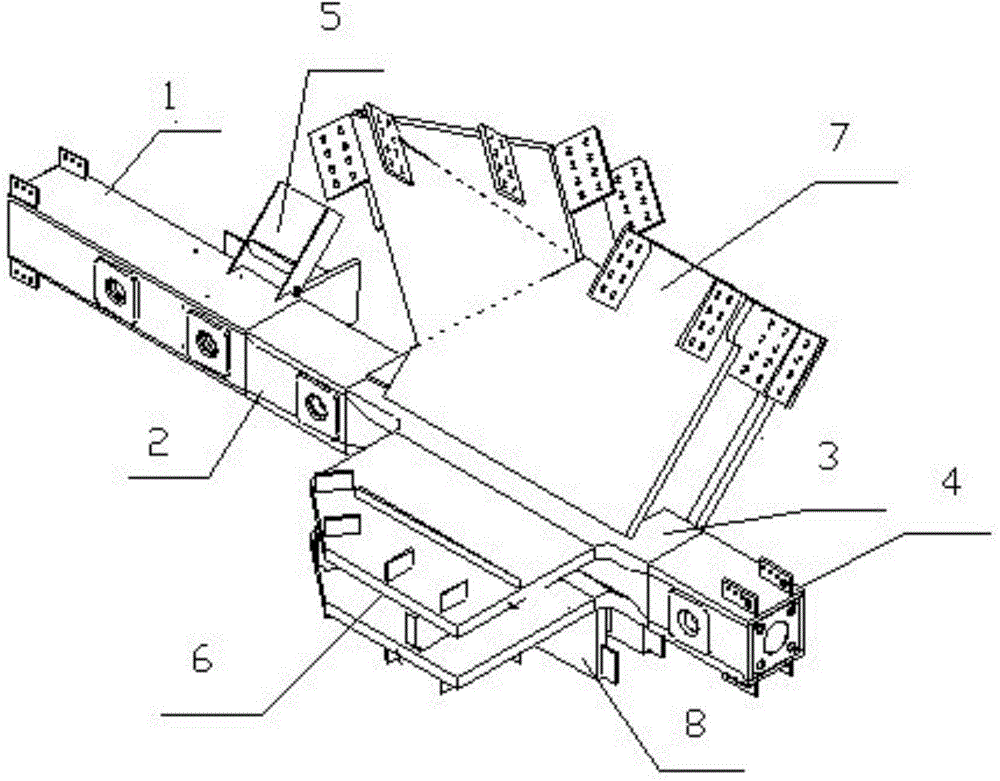

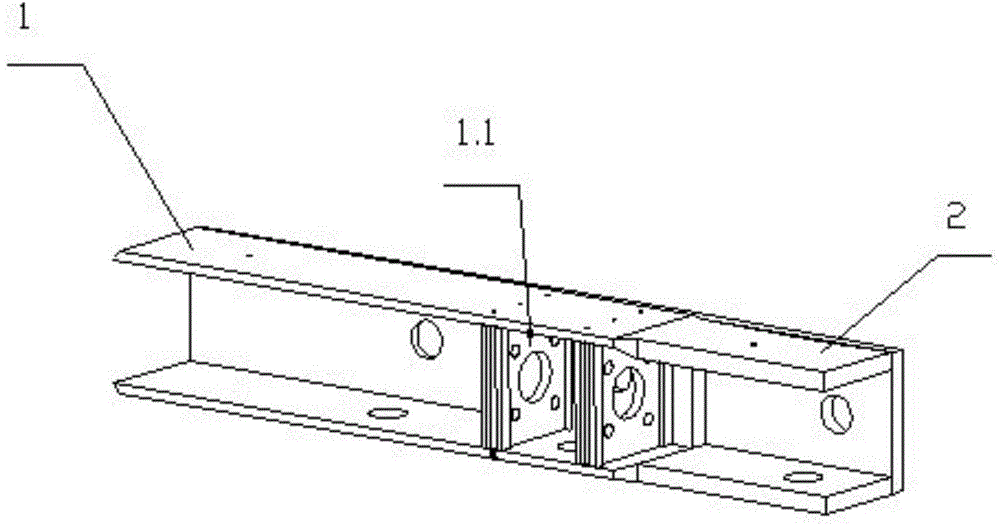

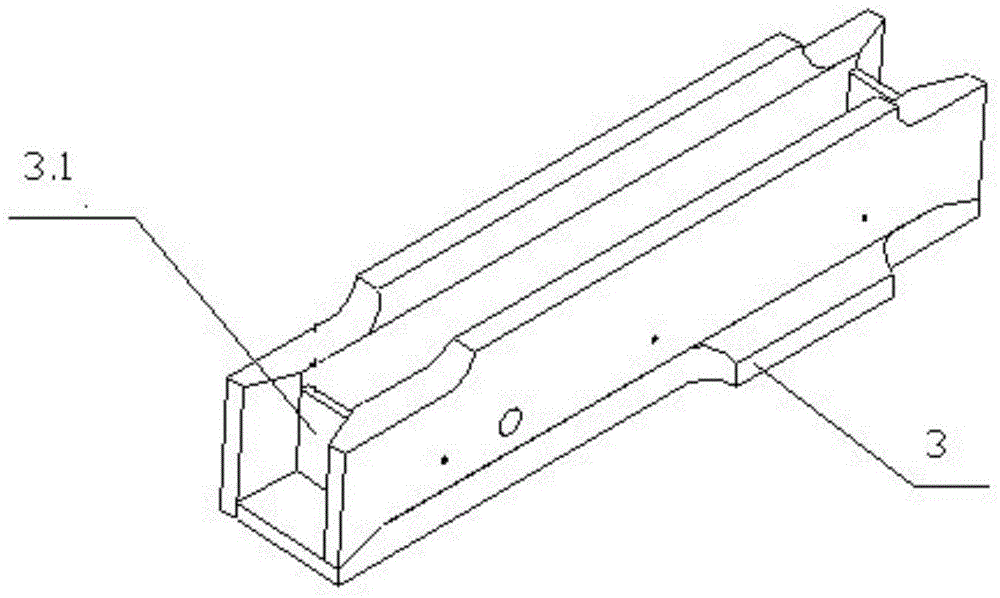

[0039] see figure 1 — Figure 5 , the present invention relates to a steel column of a thick-plate special-shaped oblique corbel truss layer, which mainly includes a medium-thick plate box-shaped column section 1 with a plate thickness of 35 mm, a first thick-plate box-shaped transition section 2 with a plate thickness of 70 mm, and a plate The ultra-thick board box column section 3 with a thickness of 150mm and the second thick board box-shaped transition section 4 with a thickness of 70mm. The medium-thick plate box-shaped column section 1, the thick-plate box-shaped transition section 2, the extra-thick plate box-shaped column section 3 and the second thick-plate box-shaped transition section 4 are sequentially connected, and in the medium-thick plate box H-shaped oblique corbel 5 is installed on one side of the column section 1, and a sub-shaped corbel 6 is arranged on one side of the ultra-thick board box-shaped column section 3, and the sub-shaped corbel 6 is composed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com