Construction method of beam longitudinal bar anchorage for stiffened steel structural column-beam column joints

A beam-column joint and steel structure technology, which is applied in building construction, construction and other directions, can solve the problems of increased engineering volume, difficult welding operations, and difficult construction, and achieves accelerated construction speed, convenient and fast opening, and improved anchorage. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

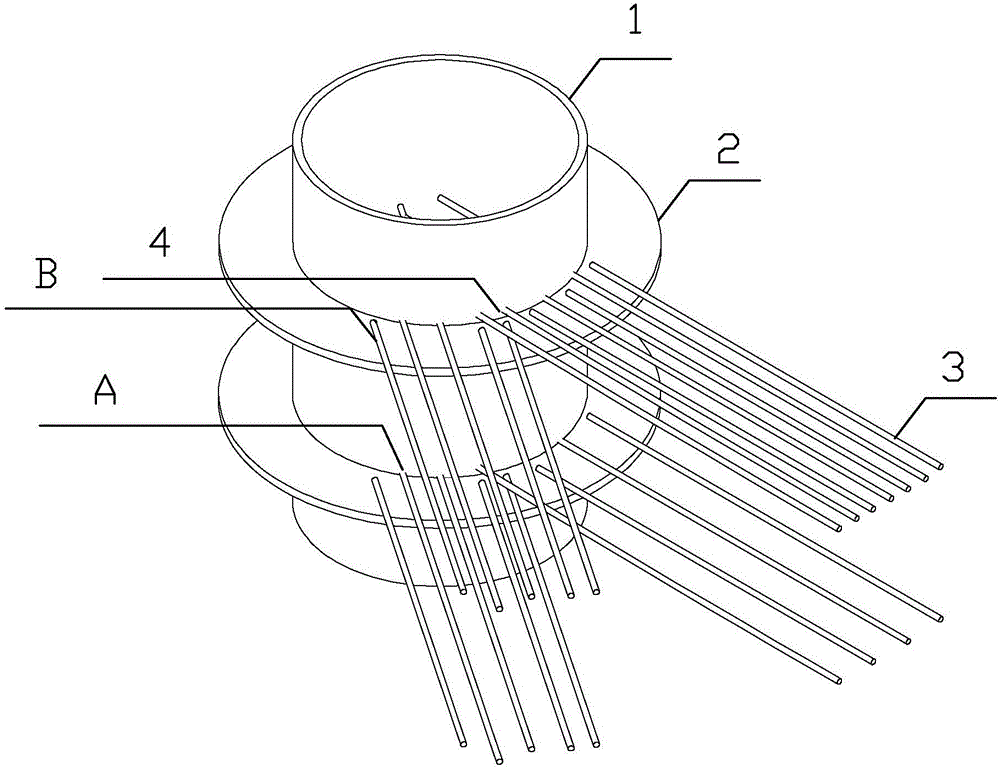

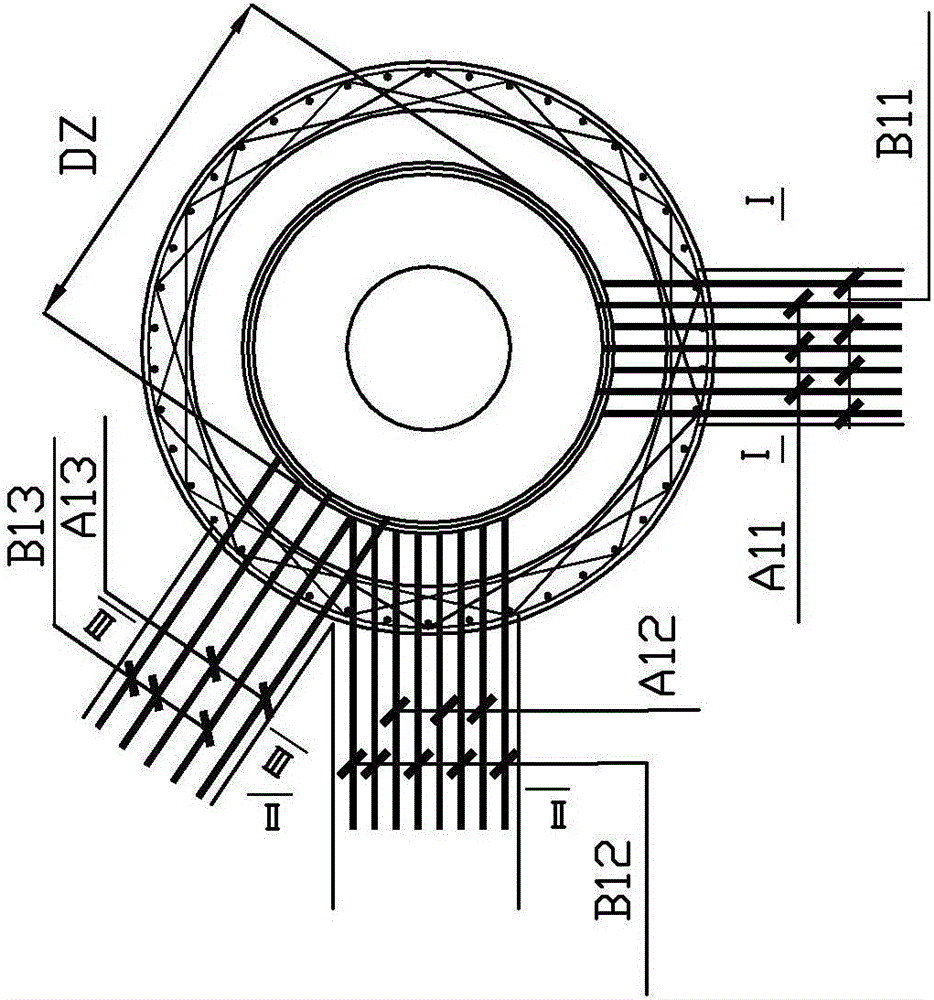

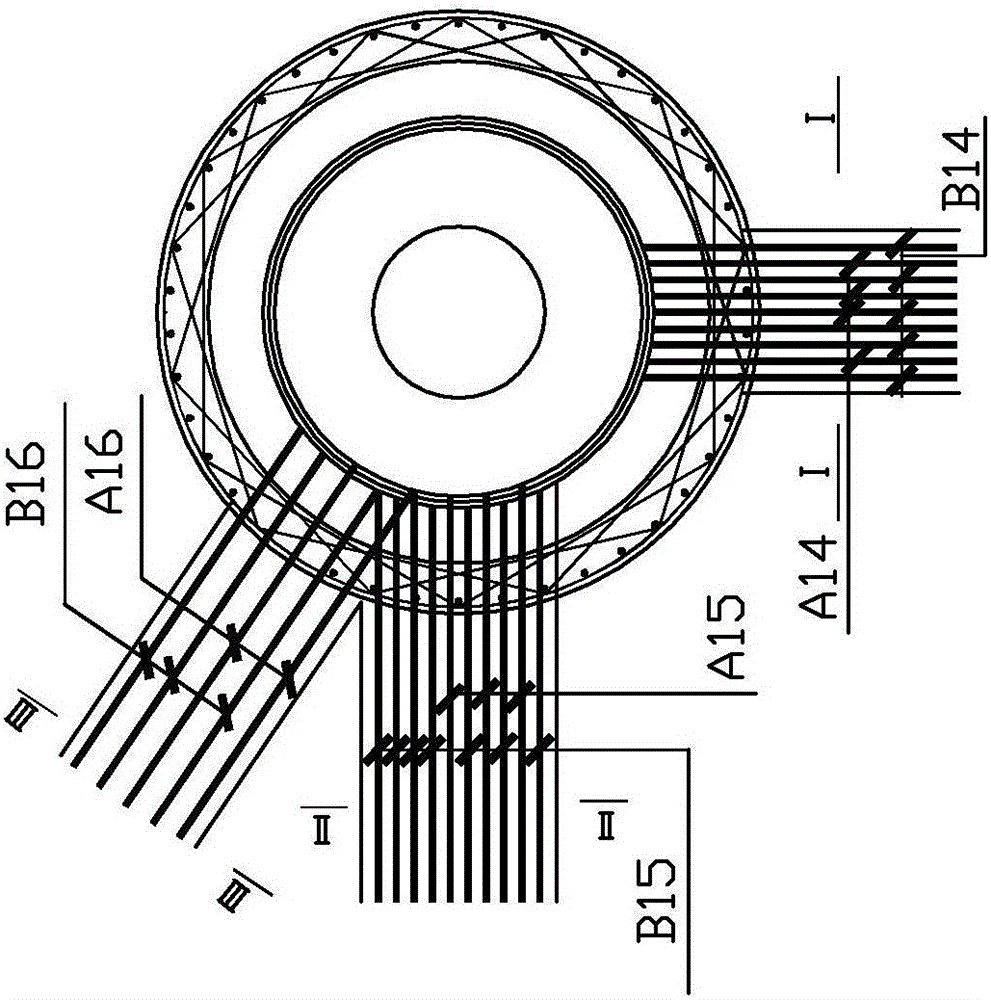

[0070] A stiff steel structure column-beam-column joint beam longitudinal bar anchoring construction method, the stiff steel structure column includes a steel bone column, and the stiff steel structure column-beam-column joint beam longitudinal bar anchorage construction method refers to a steel An anchoring construction method between bone columns and reinforced concrete beam-column joints, the method is to use welding and opening holes to interpenetrate the anchorage construction between the rigid steel structure columns and the steel bars of the longitudinal bars of the reinforced concrete beam-column joints , this method first carries out three-dimensional modeling, and uses AutoCAD and other software combining two-dimensional and three-dimensional through the detailed design to loft and model the design drawings according to 1:1 (see figure 1 -Schematic diagram of the three-dimensional modeling of the "rigid steel structure column-beam-column joint beam longitudinal reinfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com