Irregular tank body circular seam automatic welding machine

An automatic welding machine and tank technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of heavy equipment workload, unstable welding quality, large production space, etc., and reduce land occupation The effect of area and investment, saving production space, and stable welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

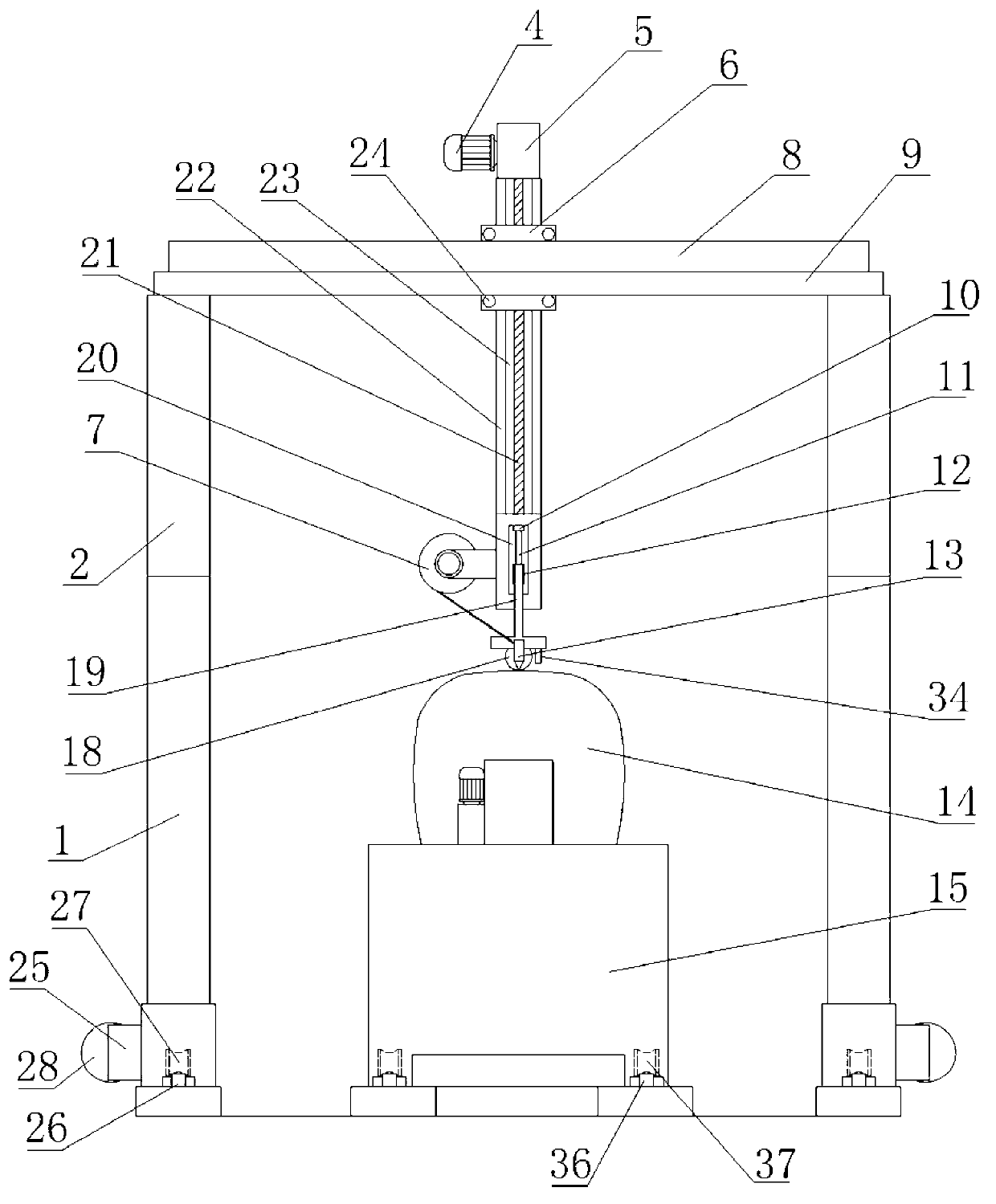

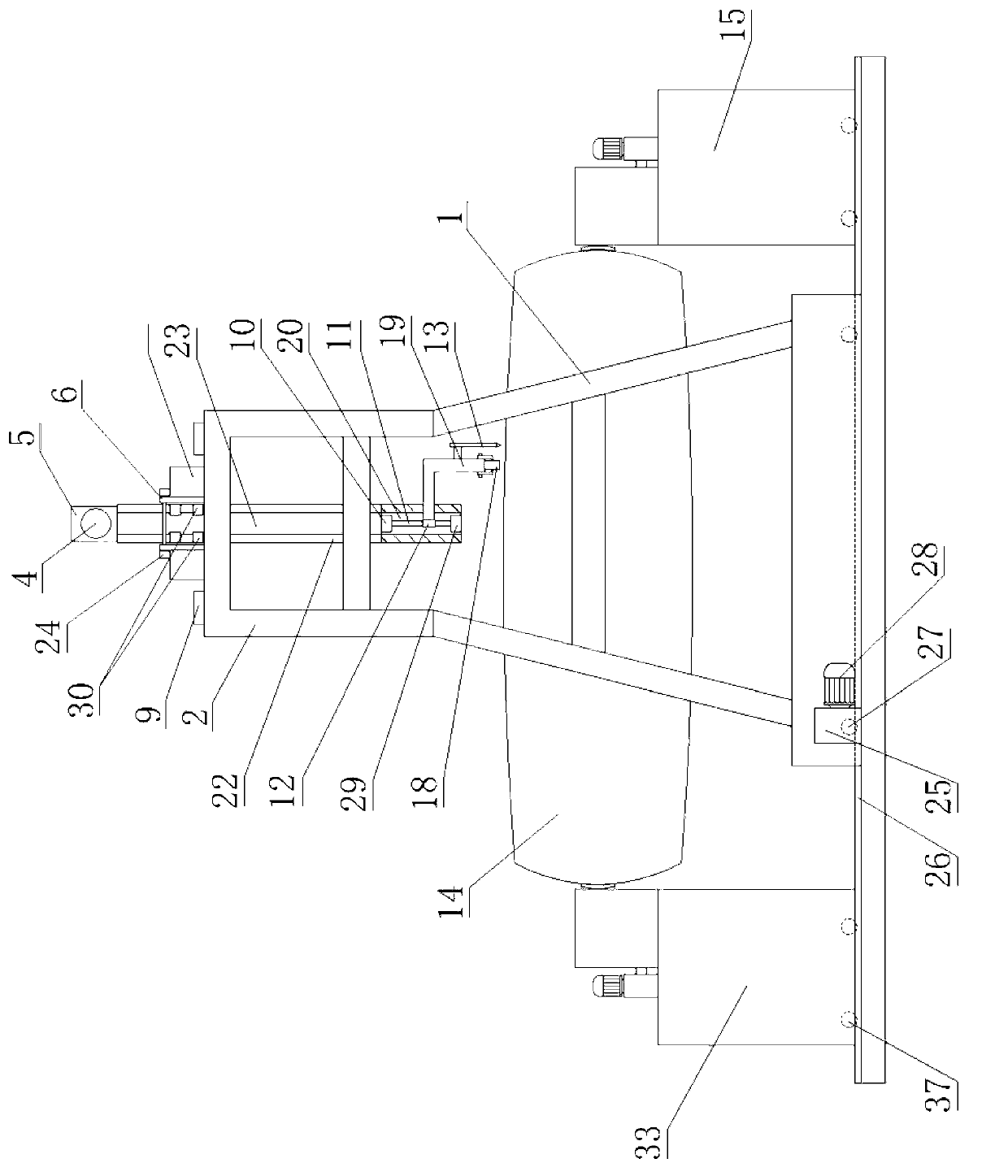

[0018] refer to figure 1 , figure 2 , The special-shaped tank girth automatic welding machine of the present invention includes a frame, a welding torch assembly 13 mounted on the frame and a wire feeding mechanism 7 for feeding welding wire to the welding torch assembly. The frame includes left and right brackets and two beams 8, the two ends of the beams 8 are respectively fixed on the tops of the two brackets, and the brackets include an upper bracket 2 and a lower bracket 1 butted together. An inspection platform 9 is provided on the outer sides of the two beams 8, and the two ends of the inspection platform 9 are respectively fixed on the tops of the left and right upper brackets.

[0019] The automatic circular seam welding machine for special-shaped tanks also includes a welding torch horizontal moving mechanism for driving the weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com