Iolite-mullite-andalusite thermal-shock-resistant brick and preparation method thereof

A cordierite and andalusite technology is applied in the field of high thermal shock refractory materials for ceramic burners of iron-making hot blast stoves, which can solve the problems of low bulk density, high porosity, softening and fragmentation, and achieve excellent comprehensive performance and extended use. Longevity and effect of improving thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

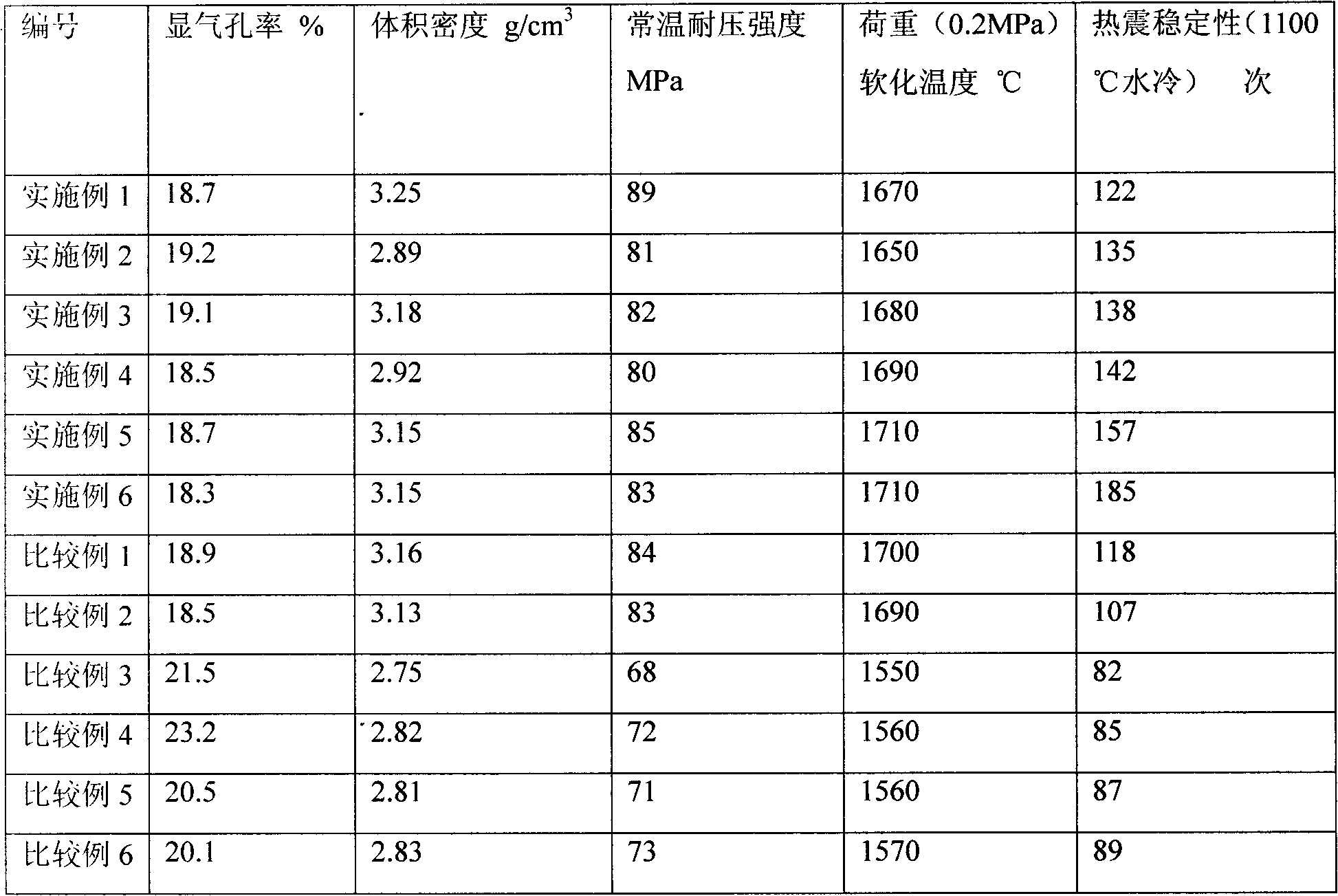

Examples

Embodiment 1

[0044] A cordierite-mullite-andalusite thermal shock-resistant brick, the proportion of which is: fused mullite: 15wt%, brown corundum: 5wt%, tabular corundum: 32wt%, andalusite: 20wt%, oxidation Aluminium powder: 10wt%, cordierite: 12wt%, clay: 6wt%. The mineral particles are prepared into fine powder by dry blending method; the density of the fine powder is 1.20g / cm 3 The dextrin liquid is mixed and milled uniformly; the milled material is made into a brick with a forming machine, and the brick is dried in a natural drying oven to make the moisture less than 1.0%, and then sintered in a sintering furnace at 1400°C for 16 hours.

Embodiment 2

[0046] A cordierite-mullite-andalusite thermal shock-resistant brick with the following proportions: fused mullite: 42wt%, brown corundum: 5wt%, tabular corundum: 10wt%, andalusite: 15wt%, oxidation Aluminium powder: 10wt%, cordierite: 12wt%, clay: 6wt%. The mineral particles are prepared into fine powder by dry blending method; the density of the fine powder is 1.20g / cm 3 The dextrin liquid is mixed and milled uniformly; the milled material is made into a brick with a forming machine, and the brick is dried in a natural drying oven to make the moisture less than 1.0%, and then sintered in a sintering furnace at 1400°C for 16 hours.

Embodiment 3

[0048] A cordierite-mullite-andalusite thermal shock-resistant brick with the following proportions: fused mullite: 25wt%, brown corundum: 15wt%, tabular corundum: 25wt%, andalusite: 15wt%, oxidation Aluminum powder: 5wt%, cordierite: 12wt%, clay: 3wt%. The mineral particles are prepared into fine powder by dry blending method; the density of the fine powder is 1.20g / cm 3 The dextrin liquid is mixed and milled uniformly; the milled material is made into a brick with a forming machine, and the brick is dried in a natural drying oven to make the moisture less than 1.0%, and then sintered in a sintering furnace at 1400°C for 16 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com