Dense-medium coal separation method

A dense medium coal preparation and clean coal technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of low ash content in the underflow, high ash content in the overflow, and failure to achieve normal separation, and achieve accurate classification , the effect of improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

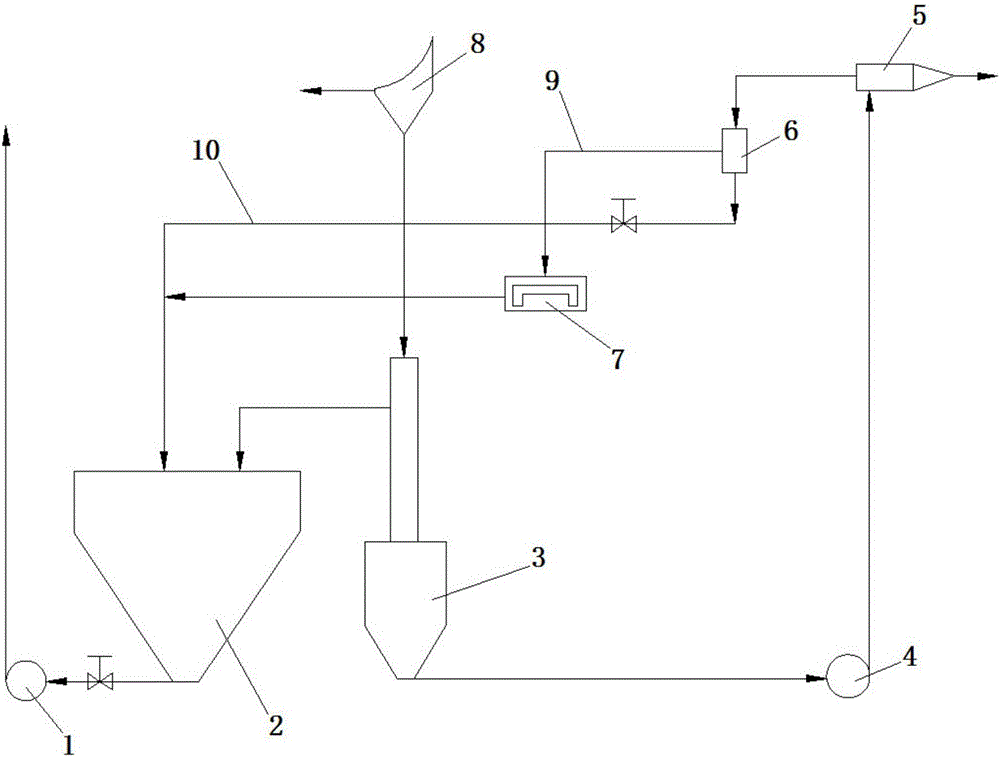

[0035]According to this embodiment of the present invention, regardless of whether the content of raw coal with a particle size of 1-0 mm is at the upper limit, middle or lower limit, the normal operation of the raw coal dense medium cyclone can be guaranteed, and the precise separation of 1-0 mm raw coal can be finally realized.

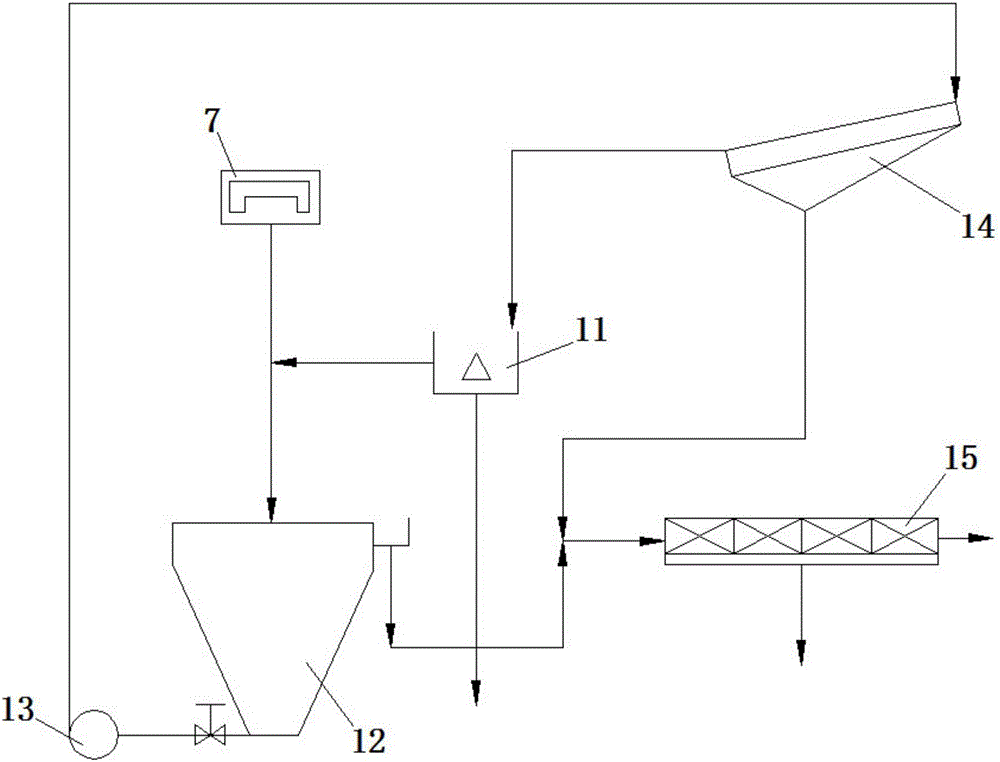

[0036] In the existing dense medium coal preparation process, it is theoretically possible to effectively classify 1-0.1mm materials. But in practice, curved sieves with 0.5mm or 0.4mm sieve slots are usually used for classification, so qualified clean coal with a particle size of 0.4-0.1mm cannot be effectively separated. This part of the material will enter the subsequent flotation process, which not only increases the workload of flotation, but also causes secondary pollution to the qualified coarse and clean coal.

[0037] figure 2 Another embodiment according to the invention is shown. According to this embodiment of the present invention, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com