Three-jaw chuck with wedge blocks

A three-jaw chuck and wedge block technology, applied in the direction of the chuck, etc., can solve the problems of the workpiece position change and the short holding part, and achieve the effect of stably clamping the workpiece and lengthening the clamping depth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

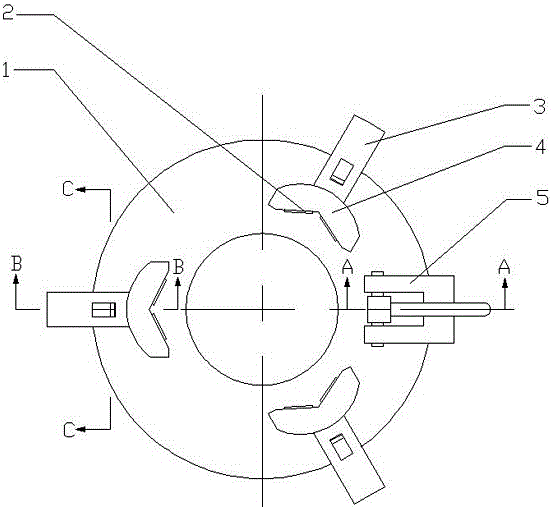

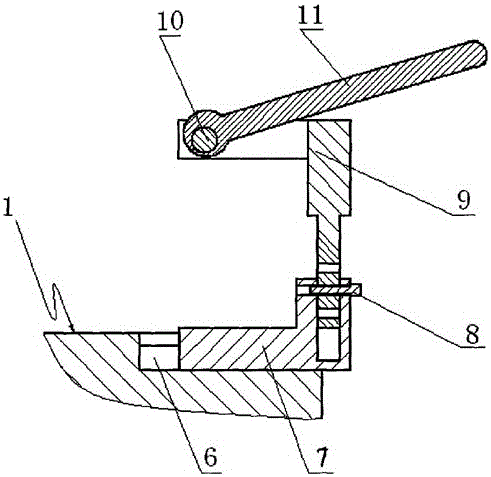

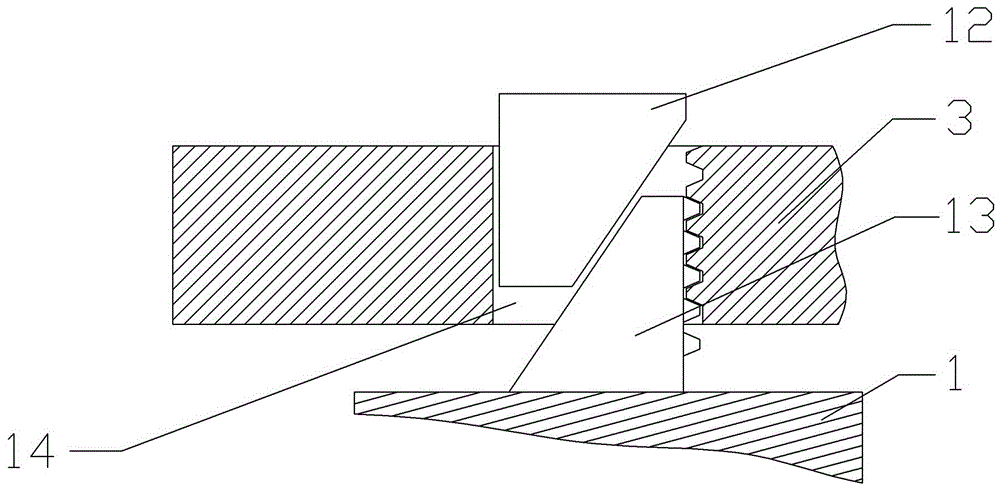

[0017] Embodiment 1: basically as attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown:

[0018] The present invention includes a chuck body 1 and three jaws of the same structure, and the chuck body 1 is provided with a workpiece pressing mechanism 5, which includes a frame-shaped sliding seat, a small shaft 10 and a The eccentric hand wheel 11 that the small shaft 10 rotates, the frame-shaped sliding seat has an upper opening plate 9 and a lower sliding bar 7 connected in parallel with the upper opening plate 9, and the lower sliding bar 7 of the frame-shaped sliding seat The outside is provided with a longitudinal rectangular hole, and the upper opening plate 9 of the frame-shaped sliding seat has a supporting bar extending downwards and stretching into the longitudinal rectangular hole of the lower sliding bar 7, and the supporting bar of the upper opening plate 9 has a plurality of intervals. Horizontal through hole, there is a pin shaft 8 connected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com