Drilling machine blind hole automatic tapping device used for wood floor machining

An automatic tapping and tapping device technology, applied in the field of drilling machines, can solve the problems of shortening the service life of the device, reducing production efficiency, unfavorable use, etc., and achieve the effect of stably clamping the workpiece, reducing mechanical wear and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

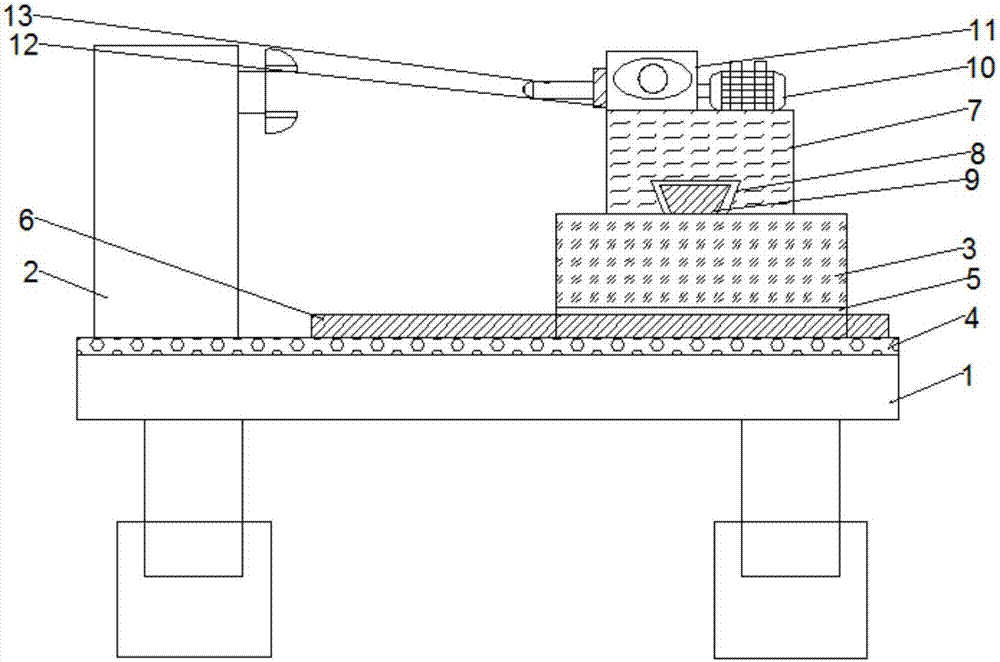

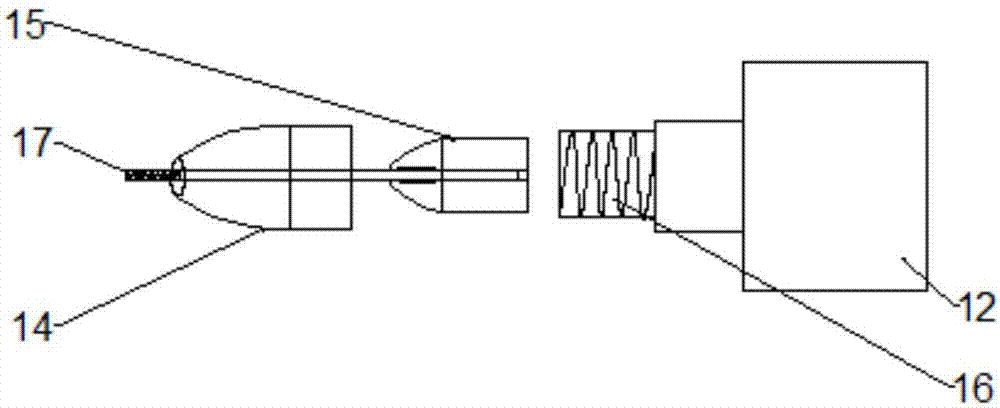

[0019] Such as figure 1 and figure 2 As shown, the present invention provides a blind hole automatic tapping device for wood floor processing, comprising a tapping device body 1, the upper part of the tapping device body 1 is provided with a workpiece holder 2 and a sliding tapping plate 3 , the workpiece holder 2 and the sliding tapping plate 3 are symmetrically installed on the surface of one end of the workbench 4 of the tapping device body 1, and the sliding tapping plate 3 connects with the workbench 4 through the transverse chute 5 on the bottom side. The upper guide rail 6 is connected, and can move horizontally and laterally through the guide rail 6. The top of the sliding tapping plate 3 is equipped with a longitudinal slide plate 7, and the bottom side of the longitudinal slide plate 7 is provided with a longitudinal chute 8 perpendicular to the guide rail, and The longitudinal sliding plate 7 is connected to the guide plate 9 of the sliding tapping plate 3 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com