Shaft part center aligning mechanism

A technology of parts and shafts, applied in the field of center alignment mechanism, can solve problems such as not being able to meet the alignment requirements of different parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

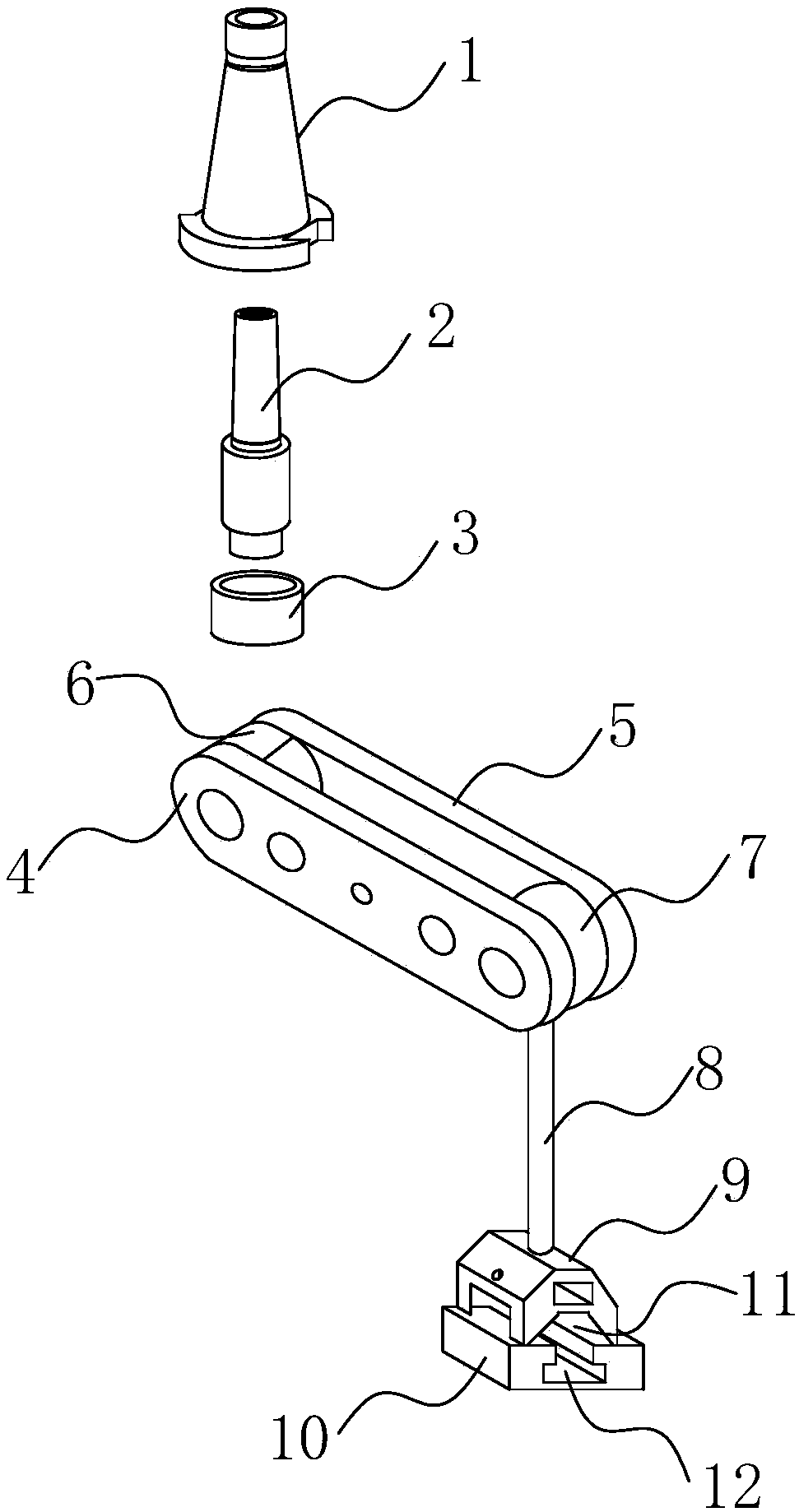

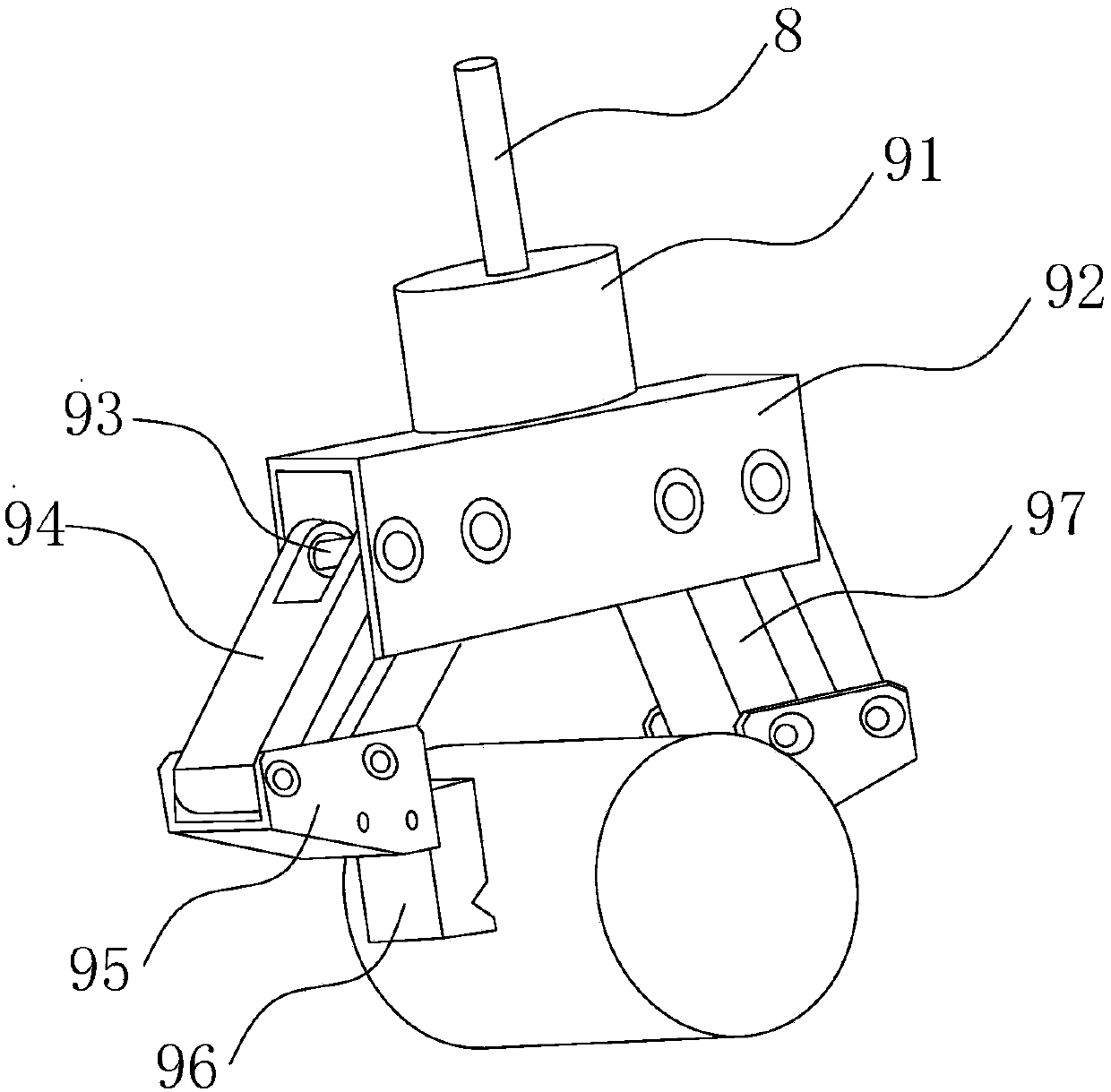

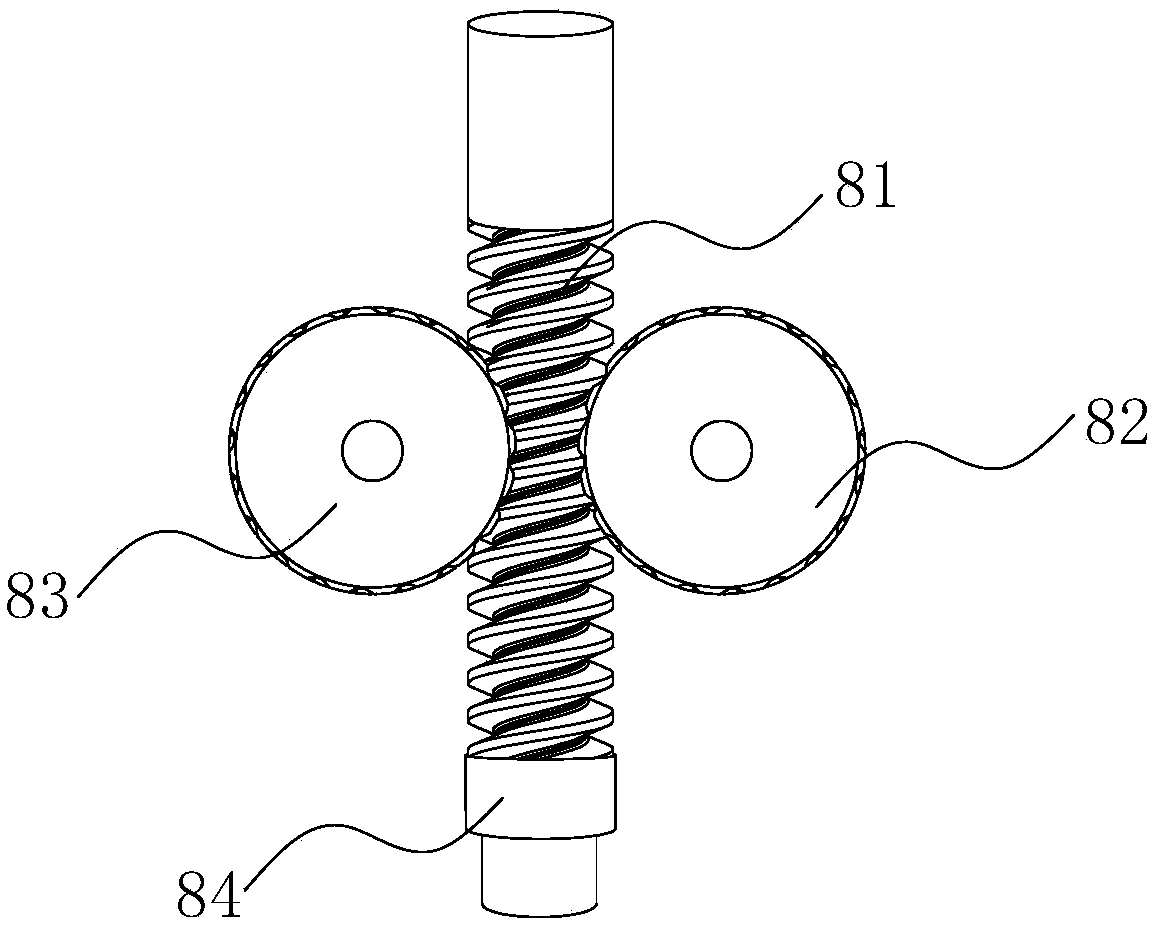

[0026] refer to Figure 1 ~ Figure 4 Shown: a center alignment mechanism for shaft parts, including a taper shank 1 used to connect with the machine tool, a shank 2 sleeved in the taper shank 1, a sliding sleeve 3 connected with the shank 2, Also includes a connecting frame 4, said connecting frame 4 includes two shaped fixed plates 5 arranged symmetrically to each other, the two shaped fixed plates 5 are connected by two limiting rotating parts, and one of the limiting rotating parts 7 is rotationally connected with it There is a rotating rod 8, the lower end of the rotating rod 8 is connected with a workpiece clamping structure 9 with a V-shaped clamping mouth, and a base 10 is provided at a corresponding position below the workpiece clamping structure 9, and the base 10 is connected with the V-shaped A T-shaped slot 12 is formed at a position corresponding to the opening 11; another limiting rotating member 6 is rotationally connected with the handle 2; After the taper han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com