Preparation method of silicon dioxide molecular sieve

A silicon dioxide and molecular sieve technology, applied in molecular sieve compounds, chemical instruments and methods, molecular sieves and alkali exchange compounds, etc., can solve the problems of unsatisfactory monodispersity of mesoporous microspheres, low industrial added value, and large environmental pressure. , to achieve the effect of obvious adsorption selectivity, high specific surface area and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

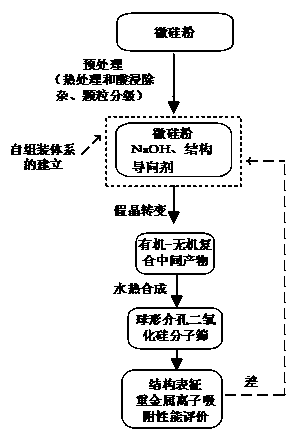

[0025] Implementation mode one: if figure 1 Shown, the preparation method of this embodiment is:

[0026] (1) Heat-treat micro-silicon powder at 500°C for 5 hours in an air atmosphere to remove C and other volatile impurities, and obtain silica powder with a particle size of 30-100nm. 95wt%, carry out acid leaching treatment (acid leaching treatment uses hydrochloric acid with a concentration of 4mol / L, the liquid-solid ratio is 10:1ml / g, and the treatment lasts for 100 minutes), and after filtering, it is cleaned. 2 The content is 97.9%;

[0027] (2) Combine the microsilica fume after acid leaching in step (1) with NaOH, structure directing agent and H 2 O according to SiO 2 : NaOH: structure directing agent: H 2 O molar ratio 1 : 0.2 : 0.1 : 200 mixed, under the condition of 90 ℃, reaction (pseudomorphic transformation) for 48 hours, then washed, filtered and dried to obtain the organic-inorganic composite intermediate product; asfigure 1 The establishment of the self-as...

Embodiment approach 2

[0029] Implementation mode two: if figure 1 Shown, the preparation method of this embodiment is:

[0030] (1) Carry out acid leaching treatment on microsilica powder (silica powder with a particle size of 200-300nm and a purity of 98wt%) (acid leaching treatment uses sulfuric acid with a concentration of 7mol / L, and the liquid-solid ratio is 50:1ml / g, treated for 90 minutes), filtered and cleaned, at this time the SiO in the silica fume 2 The maximum content is about 95.6%;

[0031] (2) Combine the microsilica fume after acid leaching in step (1) with NaOH, structure directing agent and H 2 O as SiO 2 : NaOH: structure directing agent: H 2 O molar ratio 1 : 0.4 : 0.2 : 150 mixed, under the condition of 100 ℃, reaction (pseudomorphic transformation) for 12 hours, then washed, filtered and dried to obtain the organic-inorganic composite intermediate product; as figure 1 The establishment of the self-assembled system is shown. The structure directing agent includes cationi...

Embodiment approach 3

[0034] Implementation mode three: if figure 1 Shown, the preparation method of this embodiment is:

[0035] (1) Carry out acid leaching treatment (acid leaching treatment is a mixture of hydrochloric acid and sulfuric acid with a concentration of 6mol / L in any proportion, liquid-solid Ratio of 30:1ml / g, treatment for 120 minutes), filtered and cleaned, at this time SiO in silica fume 2 The content is 98.3%;

[0036] (2) Combine the microsilica fume after acid leaching in step (1) with NaOH, structure directing agent and H 2 O as SiO 2 : NaOH: structure directing agent: H 2 O molar ratio 1 : 0.3 : 0.3 : 180 mixed, under the condition of 120 ℃, reaction (pseudomorphic transformation) for 30 hours, then washed, filtered and dried to obtain the organic-inorganic composite intermediate product; as figure 1 The establishment of the self-assembled system is shown. The structure directing agent includes cationic surfactant and nonionic surfactant, and the quality of cationic sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com