High-temperature particulate material stage cooling method and device

A granular material, graded cooling technology, used in the treatment of discharged materials, furnaces, lighting and heating equipment, etc., can solve the problems of increasing system power consumption, large material layer resistance, and increased material layer resistance, and reduce system energy. The effect of reducing energy consumption, reducing floor space and equipment specifications, and reducing cooling air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

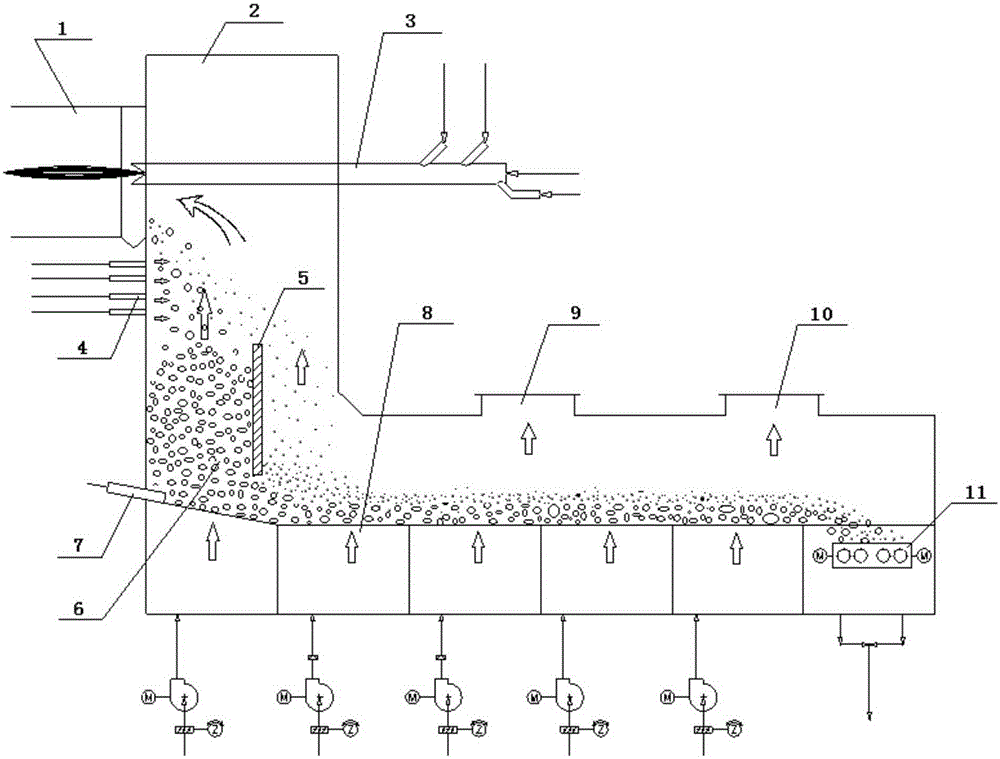

[0018] See figure 1 , a method for grading and cooling high-temperature granular materials, adopting a retaining wall 5 suspended at the bottom to horizontally divide the inlet of the cooling material bed into two regions, upstream and downstream, and adopting airflow to classify the high-temperature granular materials exiting the rotary kiln 1 and quenching, so that the classified coarse-grained materials fall into the upstream area of the cooling material bed inlet, forming a coarse-grained material bed for countercurrent heat exchange in the thick material bed, so that the classified fine-grained materials fall into the downstream of the cooling material bed inlet area, the coarse grained material that has undergone countercurrent heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com