Ex-situ sorting, cleaning and repairing device for chromium-polluted soil and cleaning and repairing technology using ex-situ sorting, cleaning and repairing device

A chromium-contaminated soil and ex-situ technology is applied in the field of soil pollution control and remediation, which can solve the problems of no step method, solid-liquid separation measures and equipment, inability to fundamentally remove heavy metals, inability to meet engineering implementation requirements, etc. Significant social benefits, saving pharmaceutical costs, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

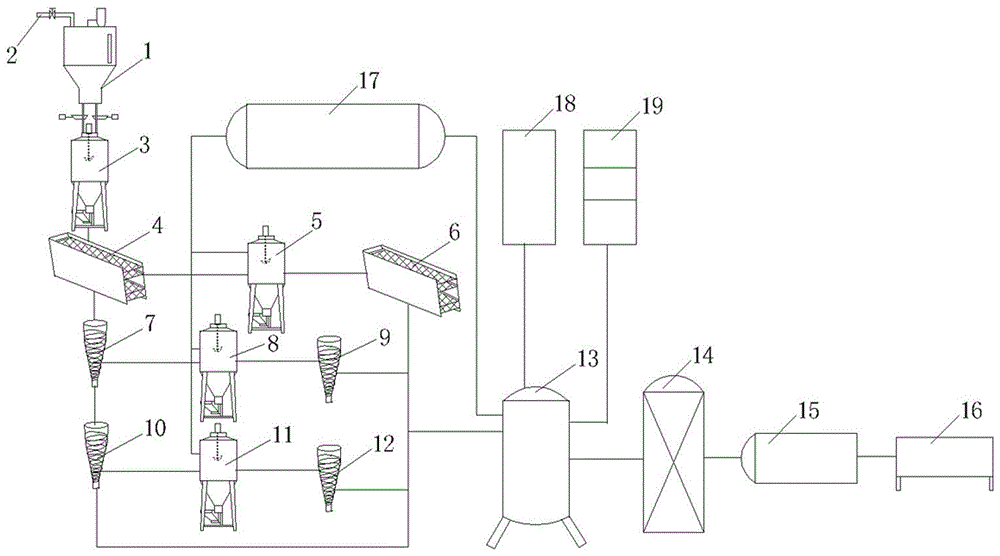

[0037] combined with figure 1 As shown, the present invention provides a kind of chromium-contaminated soil ex-situ sorting cleaning repair device, it comprises:

[0038] A raw material processing unit, which includes a slurry dispenser 1, a water delivery pipeline 2, a stirring tank I3, and a vibrating screen I4. 1 connected;

[0039] The first-stage sieved particulate matter processing unit includes a stirring tank II5 and a vibrating screen II6, the outlet of the particulate matter on the screen of the vibrating screen I4 is connected to the inlet of the stirring tank II5, and the stirring tank II5 and the vibrating screen II6 are connected in sequence;

[0040] The primary under-screen liquid treatment unit includes a primary cyclone I7, a stirring tank III8 and a primary cyclone II9, the under-screen outlet of the vibrating screen I4 is connected to the primary cyclone I7, and the primary cyclone I7 , mixing tank III8 and primary cyclone II9 are connected in sequence; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com