Method and apparatus for treating organic drainage and sludge

A sludge, organic technology, applied in chemical instruments and methods, biochemical equipment and methods, water pollutants, etc., can solve problems such as low treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0083] Next, an example in which the waste water treatment technology of the present invention is actually incorporated into a test plant will be explained, but the present invention is not limited to this example.

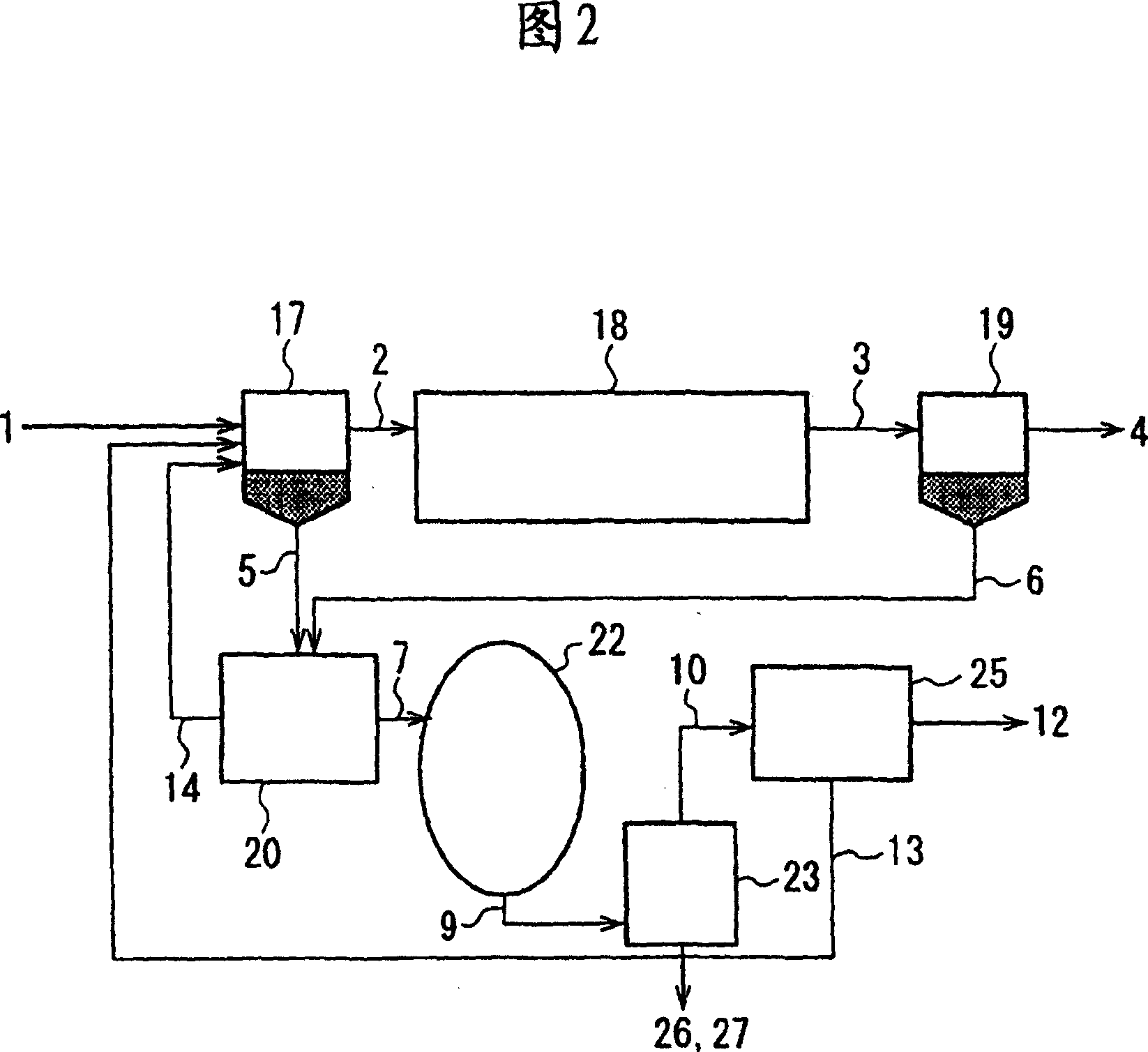

[0084] This embodiment is a pilot test, and the test uses the anaerobic digestion sludge of sewage treatment facility A, and the process flow is the same as that shown in accompanying drawing 2 above. The goal is to recover the MAP particles in the sludge as a phosphorus source and to remove harmful particles such as heavy metal particles in the sludge to improve the utilization rate of the discharged sludge as a cement raw material. Sewage treatment facility A adopts anaerobic and aerobic activated sludge treatment methods. In the anaerobic digestion chamber 22 , a mesophilic digestion process at 35° C. was carried out and the standing time was 25 days.

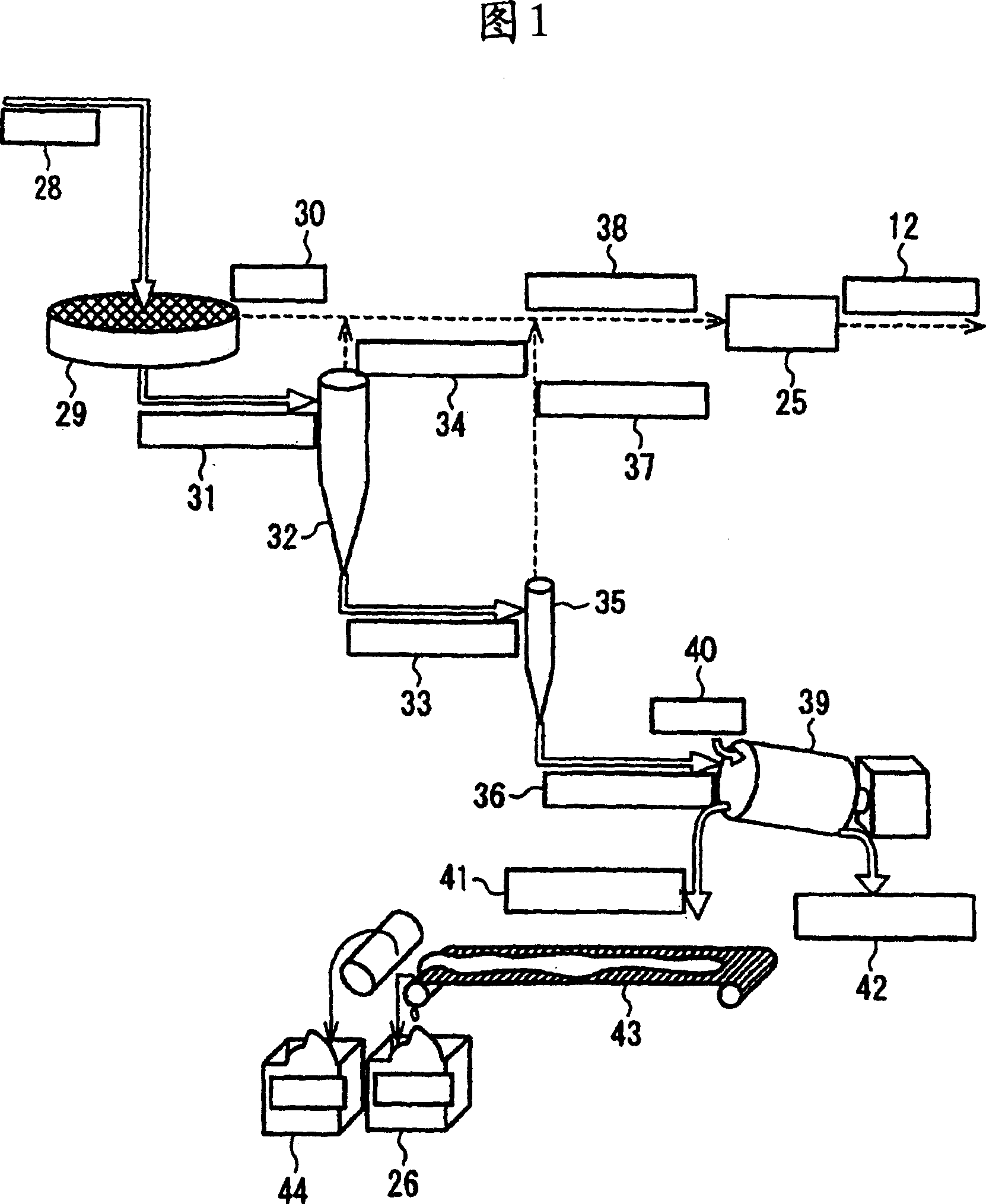

[0085] In this embodiment, the steps shown in FIG. 1 are adopted as the particle separation process 23 . Sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com