Fine particle classification measurement device, sample creation device with uniform particle concentration, and nanoparticle film forming device

A technology for measuring devices and particles, which is applied in the direction of measuring devices, particle size analysis, sampling devices, etc., can solve the problems of unavoidable membrane damage and inability to eliminate uneven distribution of particles, and achieves small damage, clear particle size range, and The effect of low kinetic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

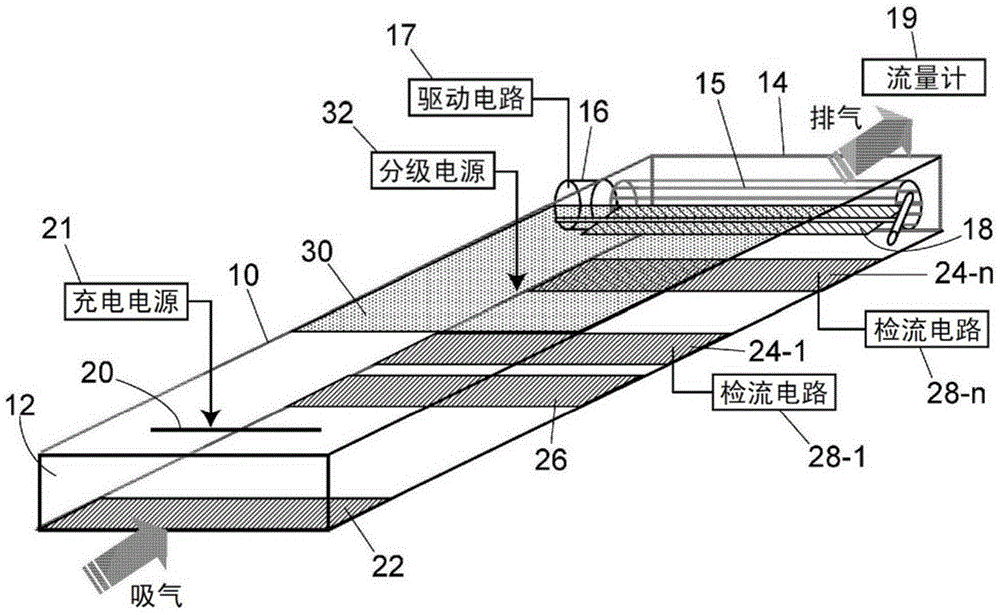

[0077] figure 1 It roughly shows an example of the particle classification measurement device of the present invention. The flow path 10 has openings at the inlet 12 and the outlet 14, and has a flat shape with a rectangular cross section in both the flow direction and the width direction of the flow path. The size and shape of the flow path are not particularly limited, for example, it is a flat rectangular parallelepiped with a length (height) of 4 mm, a width (width of flow path) of 250 mm, and a depth (length of flow path) of 450 mm.

[0078] On the outlet 14 side of the flow path 10, a fan 15 is arranged as an air blowing mechanism for sucking the sample. A motor 16 that rotates the fan 15 is driven by a drive circuit 17 . On the sample gas suction side of the fan 15, a manual butterfly valve is provided as a flow rate adjustment valve 18, and the flow rate of the sample gas can be changed by adjusting the flow rate control valve 18. The fan 15 sucks air evenly across ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com