Catalytic ozonation catalyst for wastewater treatment and preparation method thereof

A technology of ozone catalytic oxidation and wastewater treatment, applied in the field of water treatment, can solve the problems of complex catalyst preparation process, low catalyst COD removal rate, short catalyst service life, etc., and achieve long service life, no secondary pollution, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

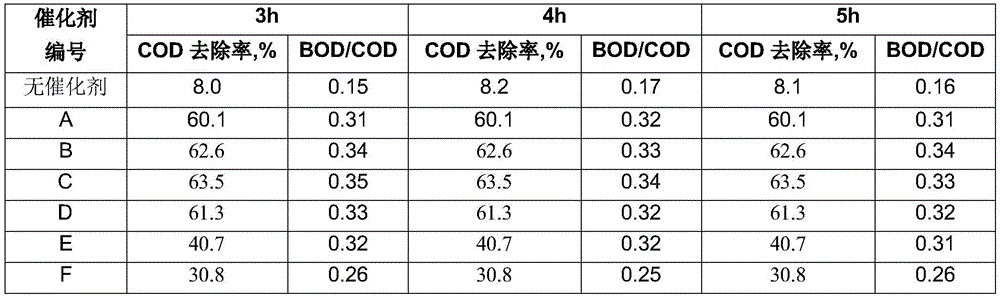

preparation example Construction

[0032] In the embodiment of the present invention, the catalyst can have a better active component distribution state by adding a dispersant during the catalyst preparation process. The dispersant in the embodiment of the present invention is a surfactant with excellent dispersing performance and wetting performance, and has the function of making various metal salts uniformly disperse on the surface of the pores of the carrier. The embodiment of the present invention provides The ozone catalytic oxidation catalyst has higher COD removal rate, longer service life and simple preparation process. After ozone catalytic oxidation treatment, the COD removal rate in refining and chemical reverse osmosis concentrated water can reach more than 60%, and the biodegradability BOD / COD of wastewater can be increased to more than 0.30; the COD removal rate in phenolic wastewater can reach about 90% . And no secondary pollution, low cost, very suitable for industrial production.

[0033] I...

Embodiment 1

[0035] Embodiment 1 prepares Fe-Mn-Na / alumina catalyst

[0036] (1) Measure 1wt.% Fe(NO 3 ) 3 , Mn(NO 3 ) 2 、NaNO 3 Solution 170ml, 43ml and 17ml were prepared as mixed impregnating solution A.

[0037] (2) Add 100 g of octadecyltrimethylammonium bromide to the above mixed impregnating solution A to prepare mixed impregnating solution B.

[0038] (3) Spray and impregnate the above mixed impregnating solution B on 500g shaped alumina carrier by equal volume impregnation method, then seal and cure for 4h, then dry at 100°C for 5h, and finally roast at 400°C for 4h to obtain catalyst A.

Embodiment 2

[0039] Embodiment 2 prepares Fe-Cu-K / activated carbon catalyst

[0040] (1) Measure 15wt.% Fe(NO 3 ) 3 , Cu(NO 3 ) 2 、KNO 3 170ml, 80ml and 10ml of the solutions were prepared as mixed dipping solution A.

[0041] (2) Add 260 g of butyl octyl phosphorodithioate to the above mixed impregnating solution A to prepare mixed impregnating solution B.

[0042] (3) Spray and impregnate the above mixed impregnating solution B on 500 g of shaped activated carbon carrier by equal volume impregnation, then cure in air for 12 h, then dry at 120 °C for 4 h, and finally roast at 600 °C for 4 h to obtain catalyst B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com