Monolithic cellular catalyst for SCR smoke denitration and preparation technology thereof

A honeycomb catalyst and integral technology, which is applied in the field of integral honeycomb catalyst preparation, can solve the problems of increasing catalyst production cost, high temperature and humidity requirements, easy cracking in drying molding, etc., to increase mechanical strength and yield, and increase electrostatic dispersion capacity , Reduce the effect of drying molding conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Preparation of monolithic honeycomb catalyst for SCR flue gas denitrification

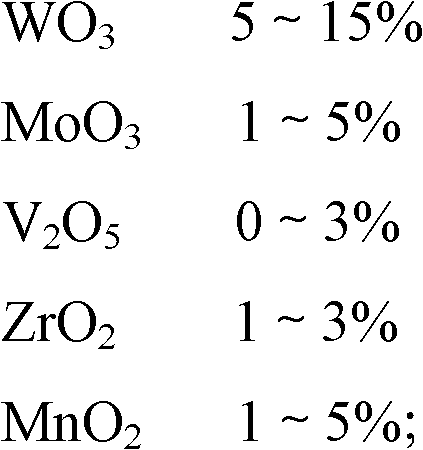

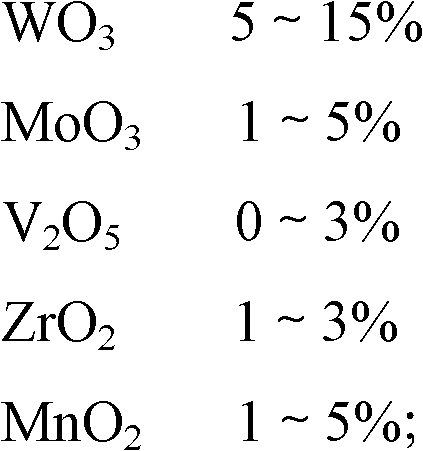

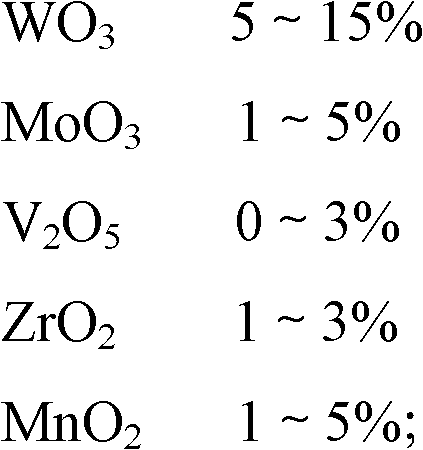

[0035] (1) Dry mix. Take 750g of nano anatase TiO 2 Powder, 20gV 2 o 5, 140gWO 3 , 50gMoO 3 , 30gZrO 2 , 10gMnO 2 . On this basis, the solid additives were 3g NSF, 112.5g polyacrylamide, 75g activated carbon powder, and 112.5g glass fiber. Put various solids together in a dry powder mixer and mix for 15 minutes.

[0036] (2) Kneading. Add 300ml of water and 112.5ml of monoethanolamine into the above mixture, and start the kneading process for 30 minutes.

[0037] (3) Practicing mud. The kneaded plastic material is transferred to a vacuum mud mixer to remove excess moisture and gas in the material.

[0038] (4) extrusion molding. The dense and uniform mud segment obtained after mud refining enters the extruder, and is extruded through a honeycomb steel die to obtain a catalyst green body.

[0039] (5) drying and roasting. Dry at 80°C for 12 hours, then raise the temperature ...

Embodiment 2

[0045] 1. Preparation of monolithic honeycomb catalyst for SCR flue gas denitrification

[0046] (1) Dry mix. Take 800g of nano anatase TiO 2 Powder, 100gWO 3 , 20gMoO 3 , 30gZrO 2 , 50gMnO 2 . On this basis, the solid additives were 3.2g PC-S, 80g carboxymethyl cellulose, 40g activated carbon powder, and 80g glass fiber. Put various solids together in a dry powder mixer and mix for 15 minutes.

[0047] (2) Kneading. Add 280ml of water and 120ml of monoethanolamine into the above mixture, and start the kneading process for 30 minutes.

[0048] (3) Practicing mud. The kneaded plastic material is transferred to a vacuum mud mixer to remove excess moisture and gas in the material.

[0049] (4) extrusion molding. The dense and uniform mud segment obtained after mud refining enters the extruder, and is extruded through a honeycomb steel die to obtain a catalyst green body.

[0050] (5) drying and roasting. Dry at 60°C for 16 hours, then raise the temperature to 110°C a...

Embodiment 3

[0056] 1. Preparation of monolithic honeycomb catalyst for SCR flue gas denitrification

[0057] (1) Dry mix. Take 800g of nano anatase TiO 2 Powder, 100gWO 3 , 20gMoO 3 , 30gZrO 2 , 50gMnO 2 . On this basis, the solid additives added are 5.6g PC-ZH, 80g carboxymethyl cellulose, 40g activated carbon powder, and 120g glass fiber. Put various solids together in a dry powder mixer and mix for 15 minutes.

[0058] (2) Kneading. Add 200ml of water and 80ml of monoethanolamine into the above mixture, and start the kneading process for 30 minutes.

[0059] (3) Practicing mud. The kneaded plastic material is transferred to a vacuum mud mixer to remove excess moisture and gas in the material.

[0060] (4) extrusion molding. The dense and uniform mud segment obtained after mud refining enters the extruder, and is extruded through a honeycomb steel die to obtain a catalyst green body.

[0061] (5) drying and roasting. Dry at 60°C for 16 hours, then raise the temperature to 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com