Wet-dry mixing electric dust remover

An electrostatic precipitator, dry and wet technology, applied in the direction of external electrostatic separator, electrostatic separation, electrode cleaning, etc., can solve the problems of reducing investment and operating costs, reduce investment and operating costs, improve dust removal efficiency, and reduce processing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

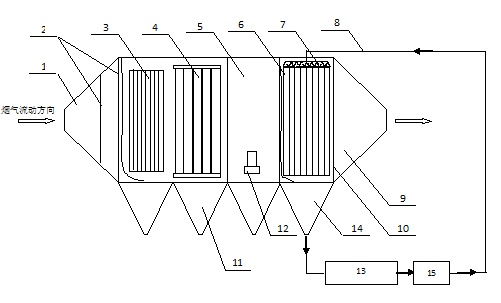

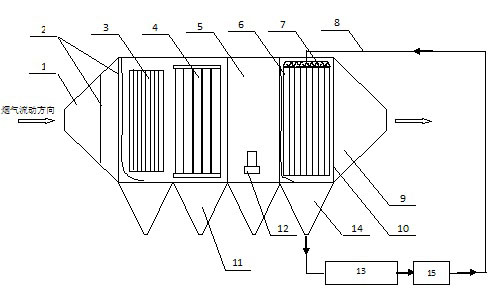

[0032] figure 1 Among them, the dry-wet hybrid electrostatic precipitator is mainly composed of an inlet smoke box 1, an air flow uniform distribution plate 2, a shell 5, an outlet smoke box 9, an outlet groove plate 10, a rapping device 12, an ash hopper 11, a water distribution device, and a collector. The water tank is composed of 14, and it is characterized in that there are several electric fields upstream in the direction of flue gas or waste gas inflow, except that the last electric field is a wet cleaning electric field using wet water film cleaning, and the rest of the electric fields use mechanical vibration and electromagnetic vibration. The dry-type ash-clearing electric field for beating or sonic cleaning, the dry-type ash-cleaning electric field and the wet-type ash-cleaning electric field are arranged in the same housing 5, and the wet-type ash-cleaning electric field is connected with the ash-cleaning water treatment and recycling system.

[0033] The wet dust...

Embodiment 2

[0037] In this embodiment, the distance between the water spray holes is 15 mm, the diameter of the water spray holes is 1.8 mm, and the central surface of the water spray holes and their water outlets forms an angle of 5 degrees with the polar plate.

Embodiment 3

[0039] In this embodiment, the distance between the water spray holes is 25 mm, the diameter of the water spray holes is 1.5 mm, and the central surface of the water spray holes and their water outlets forms an angle of 30 degrees with the polar plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com