High-electric-conductivity heavy-anticorrosion wave-absorbing powder paint

A powder coating and heavy-duty anti-corrosion technology, applied in powder coatings, anti-corrosion coatings, conductive coatings, etc., can solve the problems of undiscovered coating products and achieve good anti-corrosion detection results, high reactivity, and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

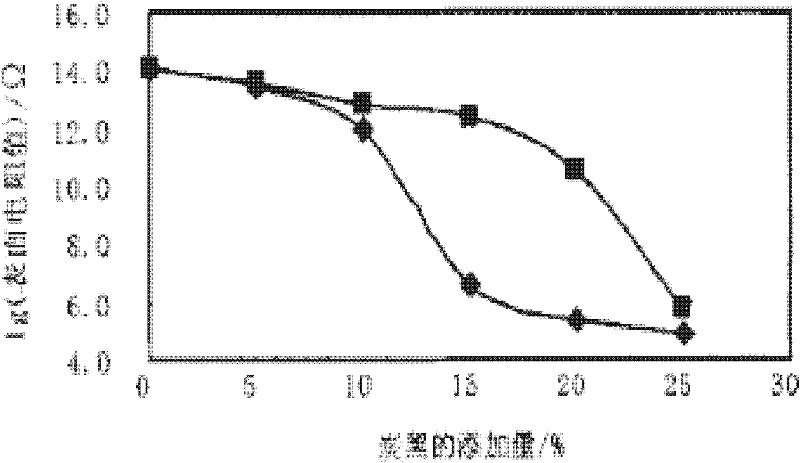

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below through specific examples. The following examples are only descriptive and not restrictive, and the protection scope of the present invention cannot be limited by this.

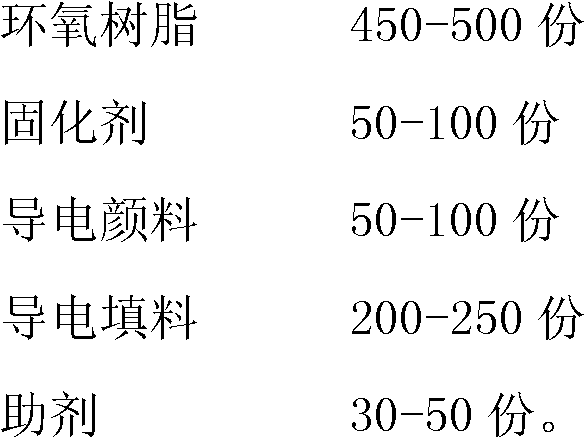

[0025] A high-conductivity heavy-duty anti-corrosion wave-absorbing powder coating, the raw material constituents and their weight parts are:

[0026]

[0027] The preparation method is:

[0028] The above-mentioned materials are added to the high-speed mixer in parts by weight, and then added to the extruder after dry mixing. The extrusion temperature is 80-90℃ for conventional melting, mixing, cooling, and tableting, and then the pulverizer Crushing, grading, sieving, and packaging will become powder coating products.

[0029] The composition and function of each raw material are described below:

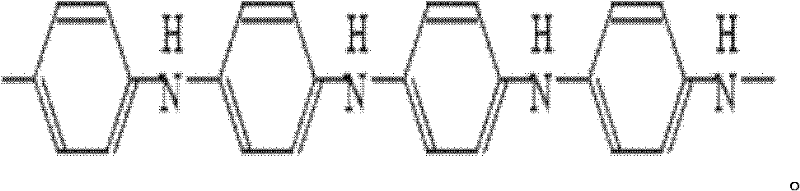

[0030] 1. Epoxy resin is a mixture of three types of epoxy resins. The composition of each component and the optimal weight parts are:

[0031] CYD014U...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com