Cement-based no-shrinkage grouting material

A non-shrinkage, grouting technology, applied in the field of cement-based materials, can solve the problems that the ettringite expansion source cannot provide plastic expansion, cannot obtain the expected use effect, and the grouting material has low compressive strength, etc., and achieves low cost and excellent rigidity. The effect of swelling, short stabilization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0043] Synthesis Example 1 Preparation of Calcium Aluminate Powder

[0044] Using the raw material ratio of 0.68 tons of bauxite, 0.66 tons of limestone, and 0.26 tons of coal, the raw material with a fineness of 0.08mm sieve 2 o 3 52.67%, CaO32.69%, SiO 2 9.02%, Fe 2 o 3 1.68%, TiO 2 1 ton of calcium aluminate powder with 2.97%, MgO0.74%, loss on ignition 0.23%, CA 2 Content 32%, CA content 17.3%, CA 2 / CA is 1.85.

Embodiment

[0045] Example Preparation of non-shrinkage grout

[0046] According to the weight ratio shown in Table 1, each component is added into the dry powder mixer at one time, and the cement-based non-shrinkage grouting material can be obtained after thorough and uniform mixing.

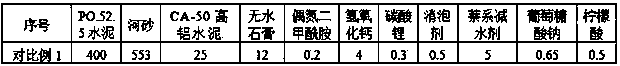

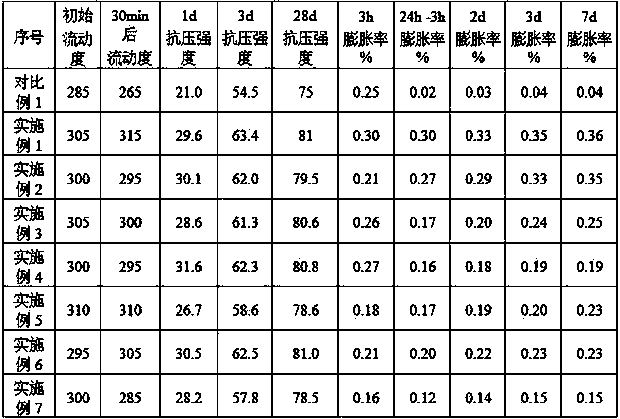

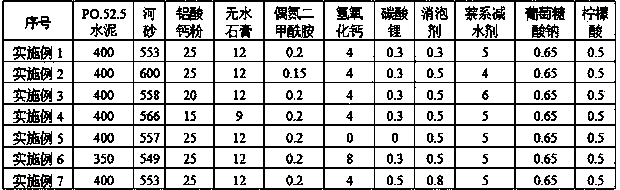

[0047] Table 1 Weight composition of cement-based non-shrinkage grout

[0048]

Embodiment 5

[0058] Examples 5-7 reflect the effect of the performance moderator employed in the present invention. Embodiment 5 does not adopt performance regulator, has lower plastic expansion and rigid expansion, but rigid expansion stable period is long; Among the embodiment 6, the consumption of calcium hydroxide is on the high side, and among the embodiment 7, the lithium carbonate consumption is on the high side, which also leads to expansion Reduced efficiency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com