Method for producing novel infant formula milk powder

A technology for formula and production method for infants and young children, applied in the production field of new infant formula milk powder, can solve the problems of cumbersome variety switching, inability to achieve breast milk, incompatibility, etc., to improve the nutritional value of products, optimize production plans, and expand production capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

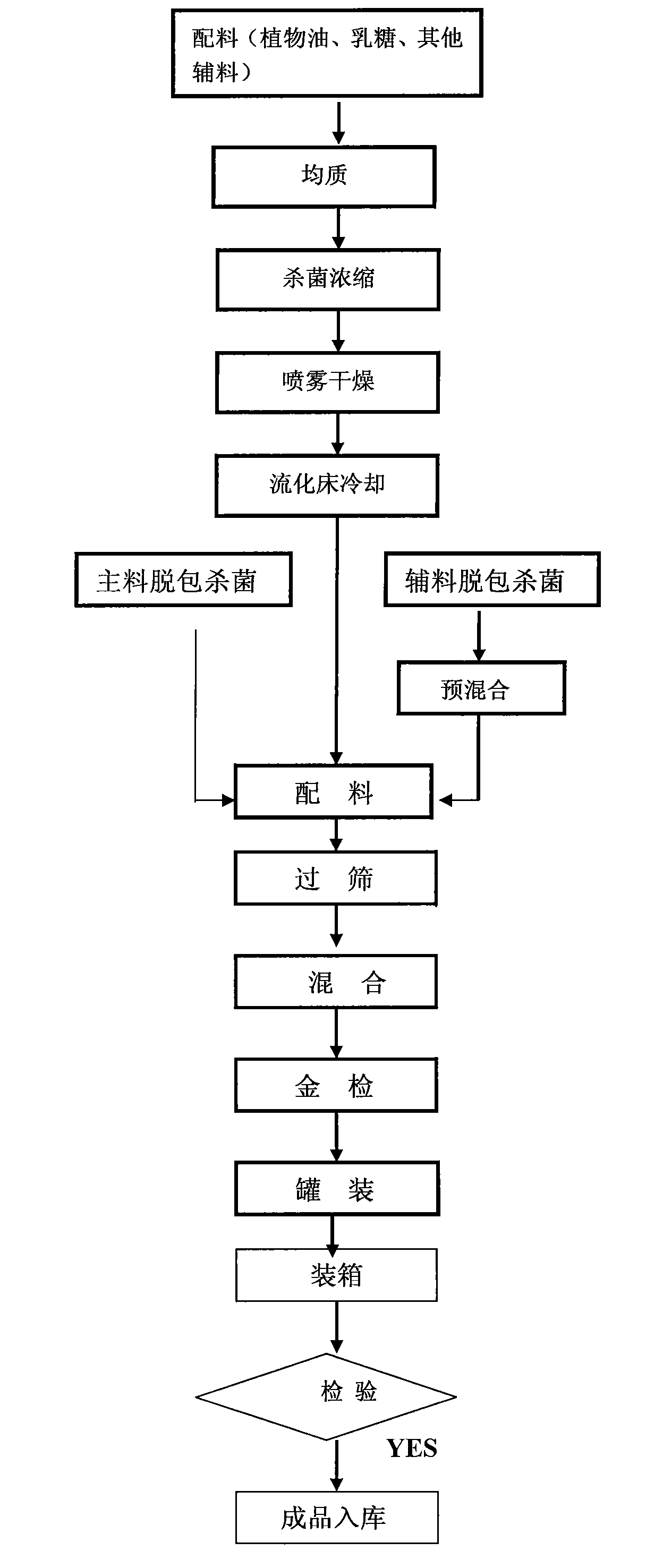

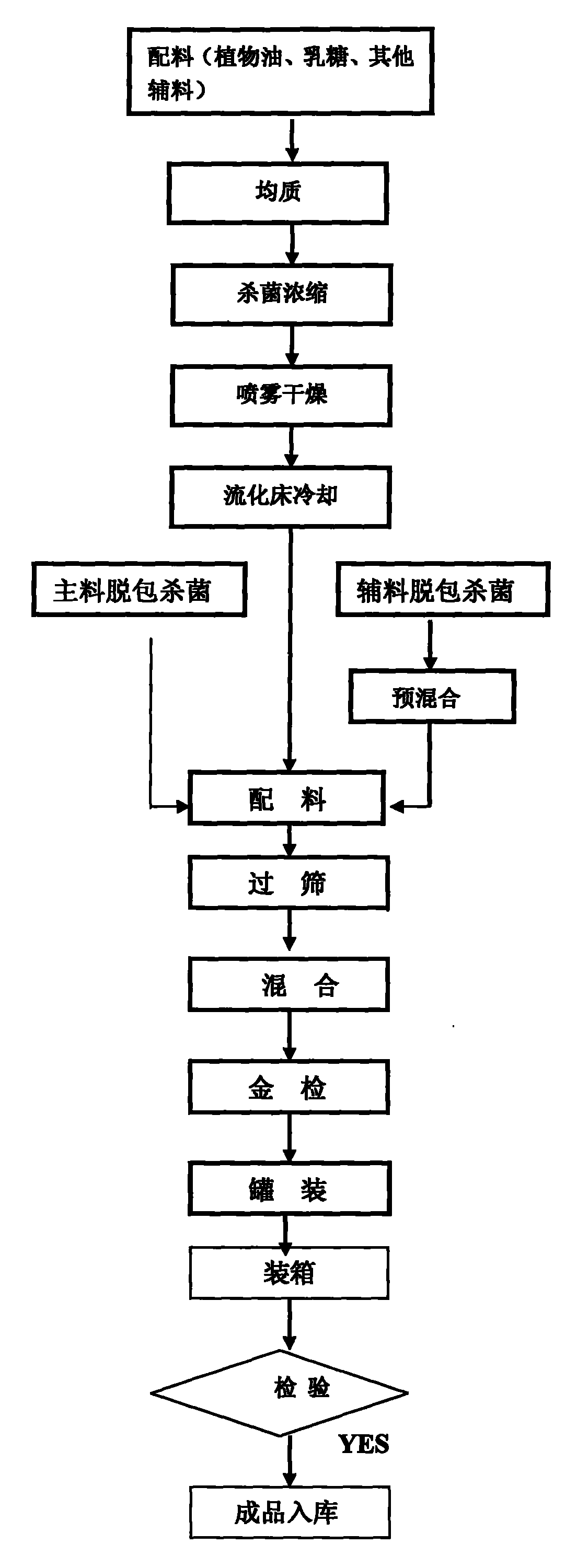

[0017] Such as figure 1 As shown, the main steps of the production method of this new type of infant formula milk powder are as follows: first, the vegetable fat powder is produced by a wet process, and then the dry process is used to mix the vegetable fat powder with other main ingredients, auxiliary materials and biologically active substances. Dry blending into different stages of infant formula.

[0018] The ratio of raw materials to produce 1 ton of vegetable fat powder is: refined vegetable oil: 500 kg, lactose: 464 kg, water: 1500 kg, casein: 30 kg, soybean lecithin: 5 kg, vitamin C: 0.5 kg, vitamin E: 0.1 kg; vegetable fat powder fat design value: 48-52%, linoleic acid design value: 12.0-14.0%, α-linolenic acid design value: 1.1-1.7%; vegetable fat powder stability (shelf life) can reach 2 years, Correspondingly, the stability (shelf life) of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com