Technology for manufacturing steel plastic composite section bar

A composite profile and manufacturing process technology, applied in the direction of the wing frame and other directions, can solve the problems of stress deformation of composite profiles, reduce the strength of composite profiles, and low plastic strength, and achieve the effects of precise geometric dimensions, guaranteed stability and clear lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

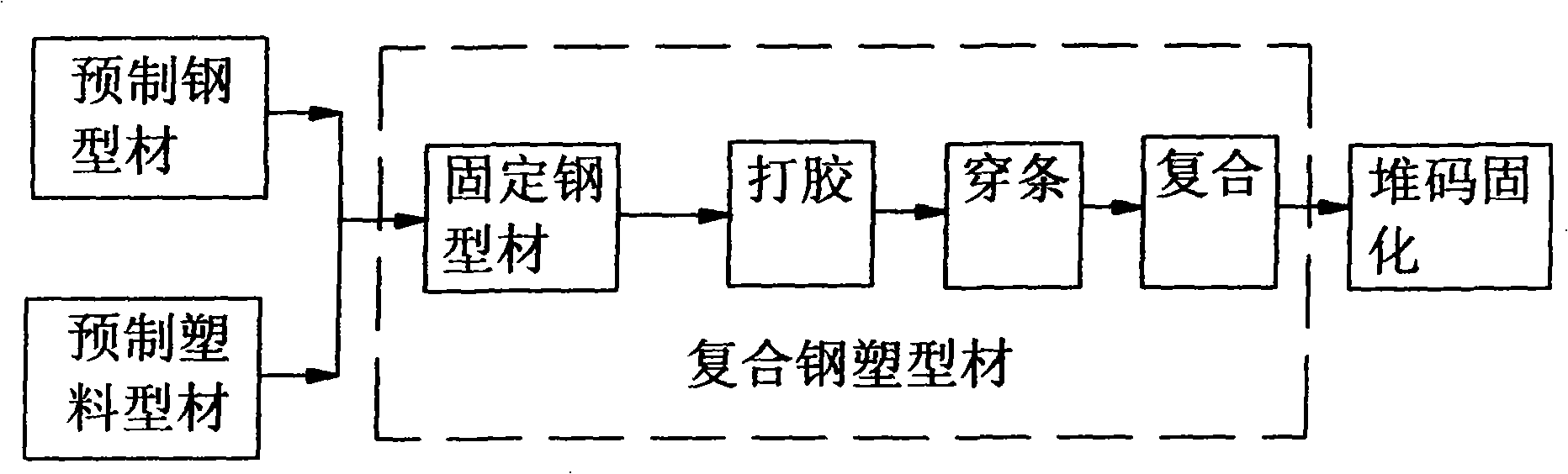

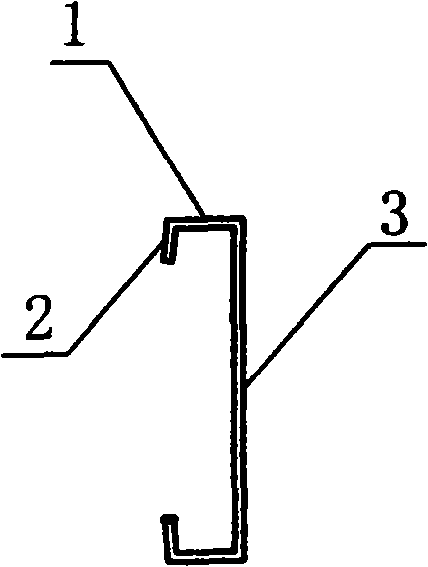

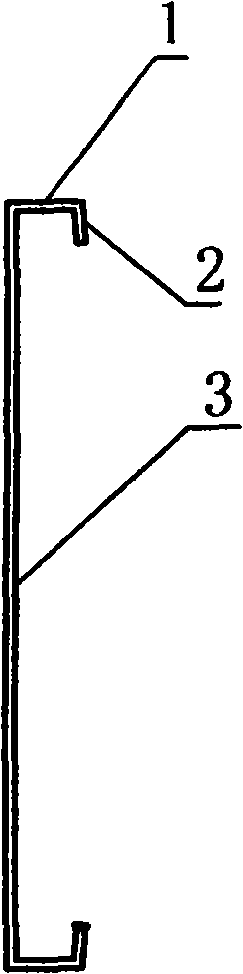

[0078] Such as Figure 1~2 As shown in 0, the specific implementation steps of a manufacturing process of a steel-plastic composite section bar are as follows:

[0079] (1) Preparation of steel profiles

[0080] ①Cut and slitting

[0081] The stainless steel strip with a thickness of 0.6mm and a width of 1000mm is cut and stripped by a slitting machine into steel strips with a width of 1 to 7 steel profile widths.

[0082] ② Preparation of steel profiles

[0083] After the completion of steps (1) to ①, the steel strips cut into strips will pass through the cold bending forming unit, adopt the existing continuous rolling process of cold bending forming, and perform side hooking after multiple passes of cold bending rolling and rolling. 2. The side plate 1 is processed, and then automatically counted and cut according to the fixed length to produce the side hook 2 with a length of 3mm and the side plate 1 with a length of 5mm, and the angle between the side hook 2 and the sid...

Embodiment 2

[0114] Such as Figure 1~2 As shown in 0, the specific implementation steps of a manufacturing process of a steel-plastic composite section bar are as follows:

[0115] (1) Preparation of steel profiles

[0116] ①Cut and slitting

[0117] With embodiment 1. The feature is: the use of color-coated steel strips with a thickness of 0.7mm and a width of 1200mm.

[0118] ② Preparation of steel profiles

[0119] With embodiment 1. The feature is: the length of the side hook 2 is 4mm, the length of the side plate 1 is 6mm, and the angle between the side hook 2 and the side plate 1 is 105°, the angle between the side plate 1 and the straight web 3 is 90°, and the bottom is straight and flat 5 steel profiles in web 3 lengths:

[0120] The length of straight flat web 3 of steel profile 1 15 is 30mm, the length of straight flat web 3 of steel profile 2 14 is 67mm, the length of straight flat web 3 of steel profile 316 is 48mm, and the length of straight flat web 3 of steel profile ...

Embodiment 3

[0132] Such as Figure 1~2 As shown in 0, the specific implementation steps of a manufacturing process of a steel-plastic composite section bar are as follows:

[0133] (1) Preparation of steel profiles

[0134] ①Cut and slitting

[0135] With embodiment 1. The feature is: the use of ordinary carbon steel strips with a thickness of 1.2mm and a width of 1000mm.

[0136] ② Preparation of steel profiles

[0137]The same as in Example 1, the feature is: the side hook 2 is 5mm long, the side plate 1 is 7mm long, and the angle between the side hook 2 and the side plate 1 is 115°, and 5 kinds of steel profiles with the following straight web 3 lengths are produced:

[0138] The length of straight flat web 3 of steel profile 1 15 is 33 mm, the length of straight flat web 3 of steel profile 2 14 is 74 mm, the length of straight flat web 3 of steel profile 316 is 53 mm, and the length of straight flat web 3 of steel profile 4 17 3 is 60mm, and the length of the straight flat web 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com