Engine life predication apparatus and refrigerator

A technology of life prediction and engine, which is applied in the direction of engine testing, household refrigeration devices, measuring devices, etc., can solve the problems of increased manufacturing cost and low reliability, and achieve the effects of improving accuracy, accurate life, and easy detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

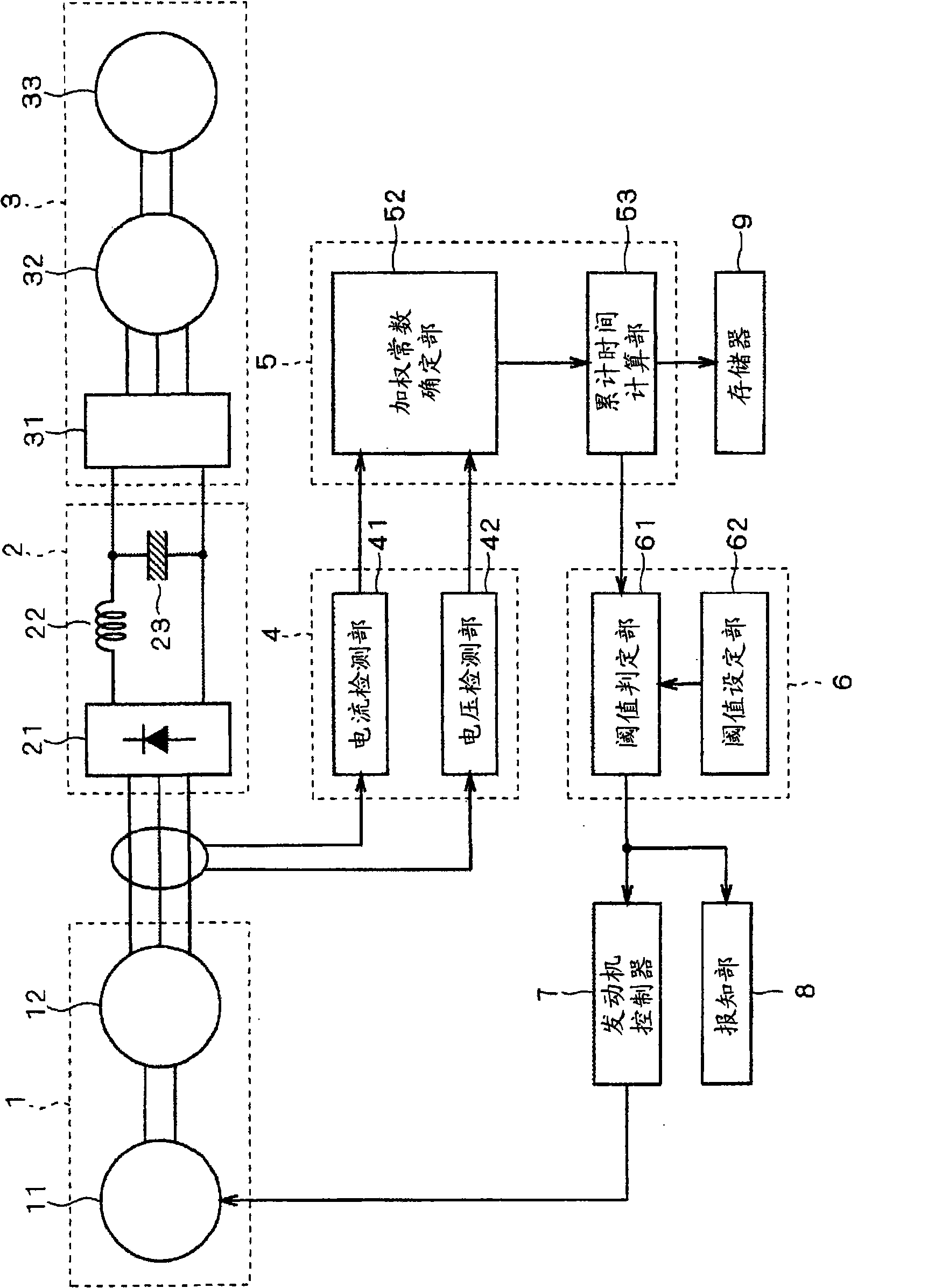

[0050] figure 1 A schematic configuration diagram showing a refrigeration device to which the engine life prediction device according to the first embodiment of the present invention is applied.

[0051] The refrigerating device includes: an engine generator 1 , an inverter 2 , a compressor drive unit 3 , a detection unit 4 , a calculation unit 5 , a determination unit 6 , an engine controller 7 , a notification unit 8 and a nonvolatile memory 9 . This refrigerating device is mounted on a trailer, for example, and has a mechanism (heat exchanger, fan, etc.) for cooling the interior of the trailer. However, illustration is omitted because it is not the essence of the present invention.

[0052] The engine generator 1 has an engine 11 and a generator 12 . The generator 12 is driven by the engine 11 as a power source, for example, generates three-phase alternating current, and supplies it to the converter 2 . In addition, the generator 12 may be a generator that generates singl...

no. 2 Embodiment approach

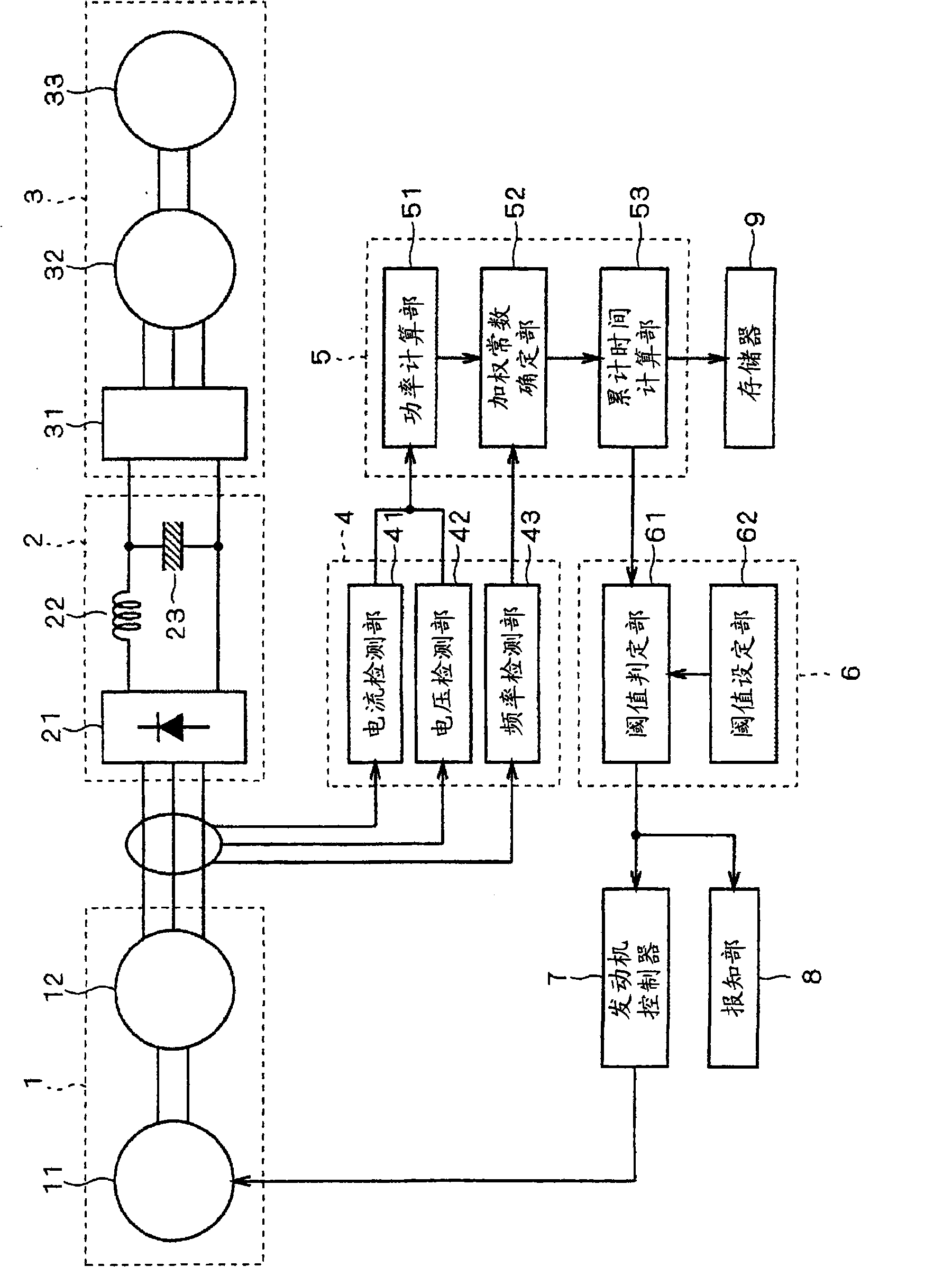

[0079] image 3 A schematic configuration diagram showing a refrigeration device to which an engine life prediction device according to a second embodiment of the present invention is applied. Compared with the first embodiment, the detection unit 4 further includes a frequency detection unit 43 , and the calculation unit 5 further includes a power calculation unit 51 .

[0080] The frequency detection unit 43 detects the frequency of the AC voltage output from the engine generator 1 .

[0081] The power calculation unit 51 calculates power using the current value detected by the current detection unit 41 and the voltage value detected by the voltage detection unit 42 .

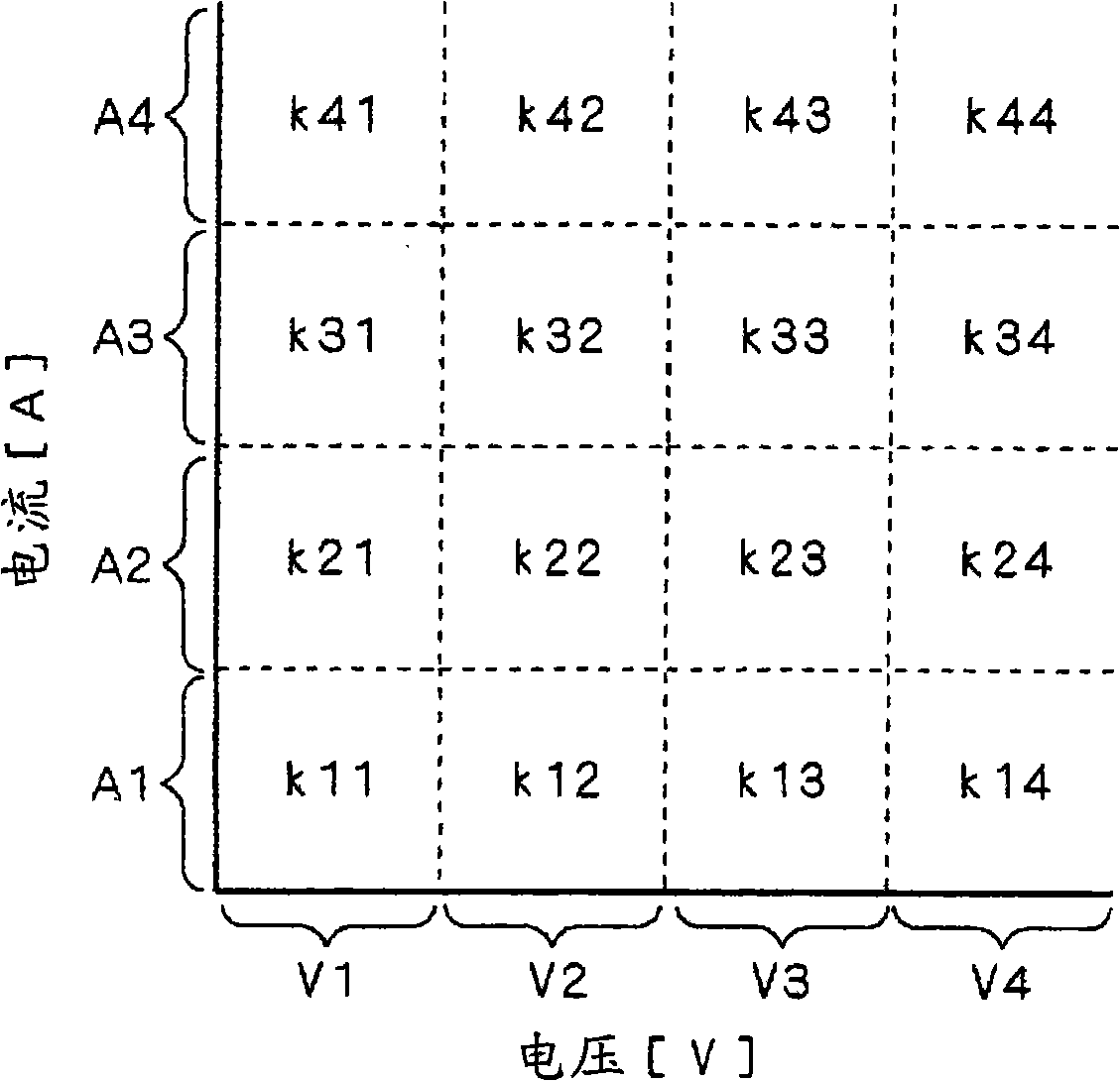

[0082] The weight constant determination unit 52 calculates the rotation speed of the engine 11 based on the frequency detected by the frequency detection unit 43 , and determines the weight constant based on the power and the rotation speed calculated by the power calculation unit 51 . Specifically, Figu...

no. 3 Embodiment approach

[0090] Figure 5 A schematic configuration diagram showing a refrigeration device to which an engine life prediction device according to a third embodiment of the present invention is applied. Compared with the second embodiment, the detection unit 4 detects the direct current output from the converter 2 .

[0091] The current detection unit 41 detects the current value output from the converter 2 on the low potential side. The voltage detection unit 42 detects a voltage between a high potential and a low potential output from the converter 2 .

[0092] The frequency detection unit 43 detects the frequency of the AC voltage from the engine generator 1 by detecting the pulsation frequency of the DC voltage output from the converter 2 . When the generator 12 is a three-phase rotating electric machine, generally, there is a relationship that the pulsation frequency of the DC voltage from the converter 2 is six times the frequency of the AC voltage from the engine generator 1 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com