NiPt@RGO composite nano catalyst for producing hydrogen by using hydrazine borane and preparation method thereof

A nano-catalyst, hydrazine borane technology, applied in the field of hydrogen storage materials, can solve the problems of low turnover frequency, catalyst stability and poor recyclability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

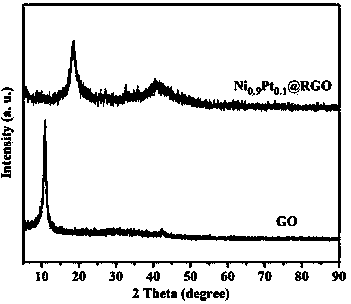

[0033] 1) Add 20 mg of cetyltrimethylammonium bromide (CTAB) and 10 mg of graphene oxide (GO) into 5 mL of water and stir well.

[0034] 2) Add 0.09 mmol nickel chloride and 0.01 mmol potassium tetrachloroplatinate to step 1), stir and sonicate for 15 minutes.

[0035] 3) Add 40 mg sodium borohydride to step 2) and stir vigorously for 30 minutes.

[0036] 4) Centrifuge, wash and dry the reaction solution obtained in step 3) to obtain Ni with a loading capacity of 42.5 wt.%. 0.9 Pt 0.1 RGO composite nanocatalyst.

Embodiment 2

[0038] Step 1) in Example 1 was changed from cetyltrimethylammonium bromide (CTAB) to polyvinylpyrrolidone (PVP). Other steps are the same as in Example 1, to obtain Ni with a load of 42.5 wt.%. 0.9 Pt 0.1 RGO composite nanocatalyst.

Embodiment 3

[0040] Change the amount of graphene oxide (GO) in step 1) in Example 1 to 5 mg. Other steps are the same as in Example 1, and the Ni with a load of 60 wt.% is obtained 0.9 Pt 0.1 RGO composite nanocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com