Rapid and simple preparation method of nano-zinc oxide

A nano-zinc oxide, fast technology, applied in the fields of nanostructure manufacturing, zinc oxide/zinc hydroxide, nanotechnology, etc., can solve the problems of long process flow, high equipment requirements, complex processing and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

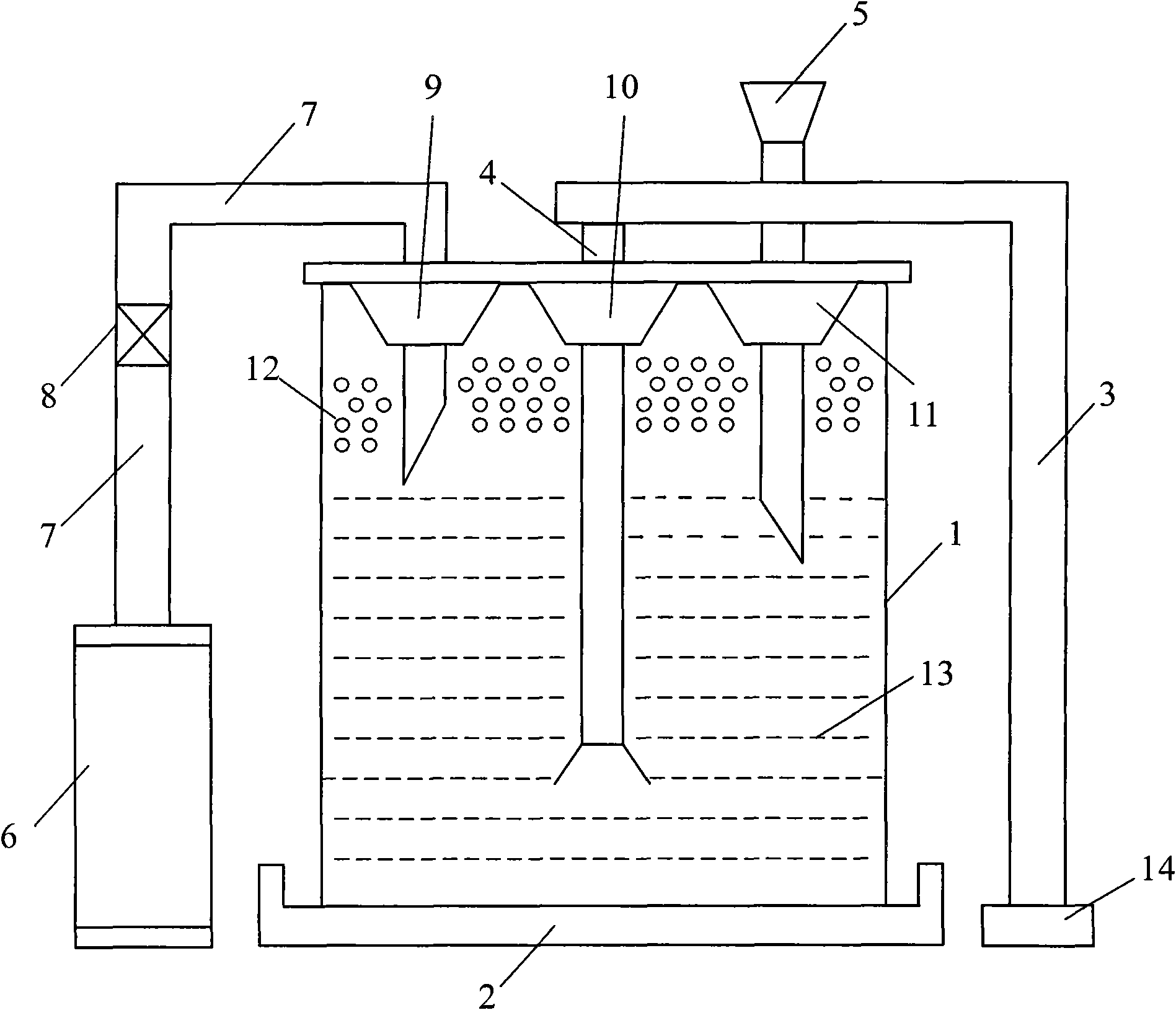

[0101] The present invention will be further described below in conjunction with accompanying drawing:

[0102] figure 1 As shown, in order to quickly prepare the zinc oxide state diagram, the beaker should be firmly placed on the base, and three cone stoppers are set on the upper part of the beaker to fix the argon tube, magnetic stirrer, and adding funnel. The upper part of the beaker is filled with argon gas, and the lower part is Zinc chloride aqueous solution + sodium hydroxide aqueous solution + oleic acid + absolute alcohol mixed solution.

[0103] To operate in sequence, the position and steps are correct.

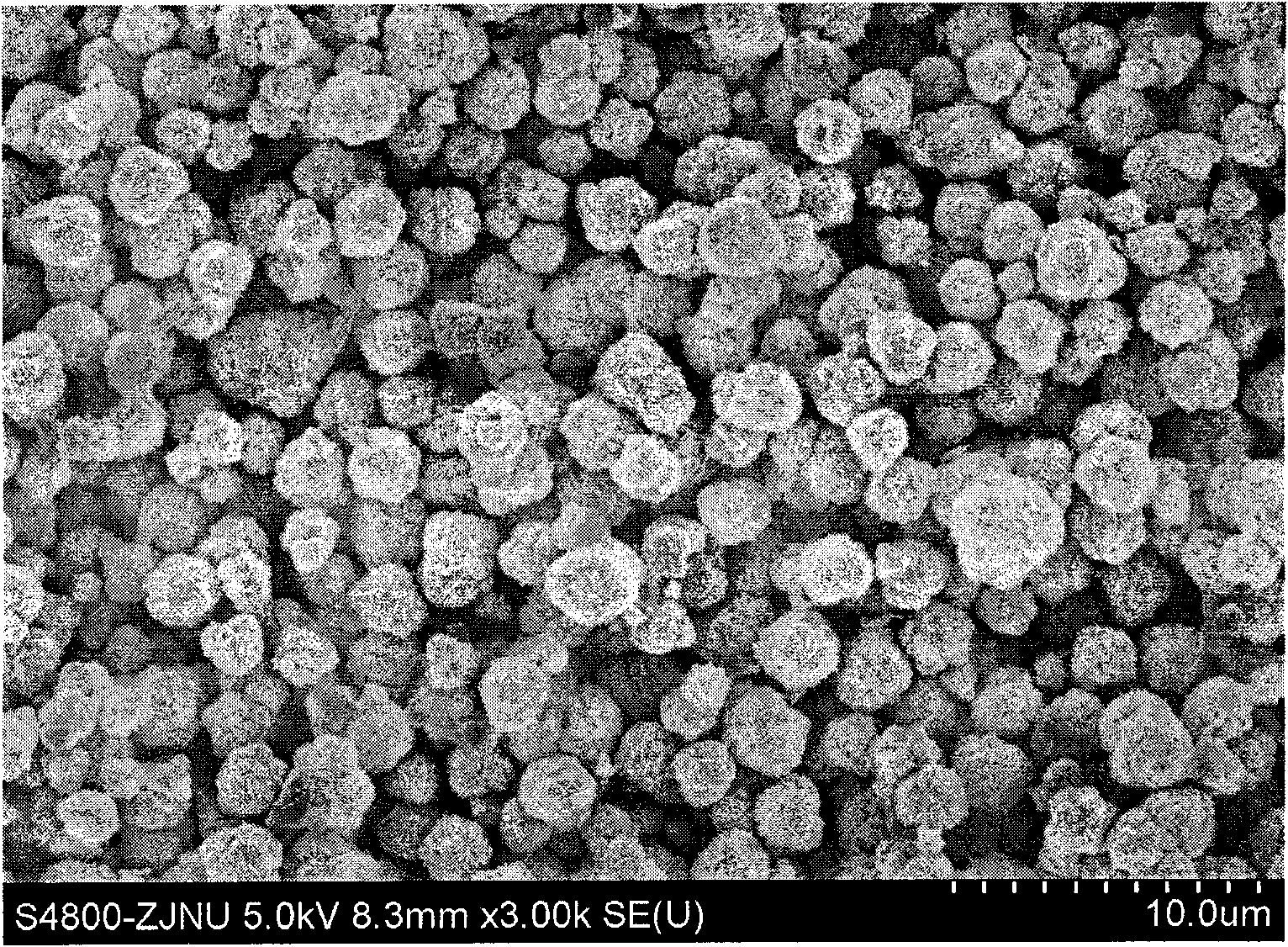

[0104] figure 2 As shown, it is the morphology diagram of the particle arrangement of the zinc oxide product, and the particles are neat, regular and clear.

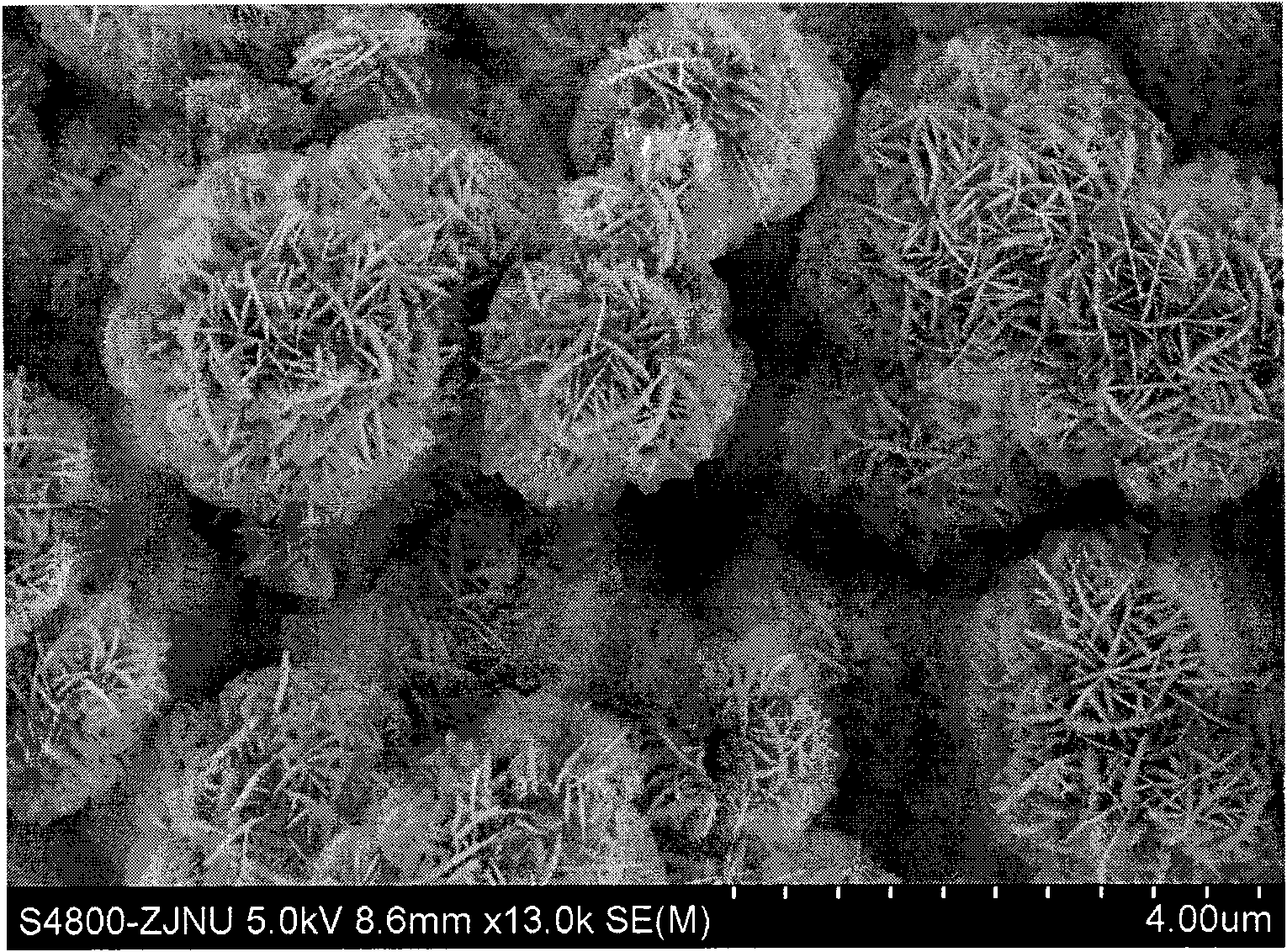

[0105] image 3 , 4 As shown, it is the state diagram of zinc oxide single crystal particles, and the single crystal is petal-shaped, with the flower core opening radially outward.

[0106] Figure 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com