Mask plate carrying table and evaporation system

A technology of mask plate and metal mask plate, which is applied in the field of mask plate carrier and evaporation system, can solve problems such as thin thickness, and achieve the effect of improving product yield, pattern shape and outline clear, and gap reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

[0038] In order to facilitate the following description, the following is combined with the appendix Figure 1-Figure 3 The application scenarios of the mask stage provided by the embodiment of the present invention are described:

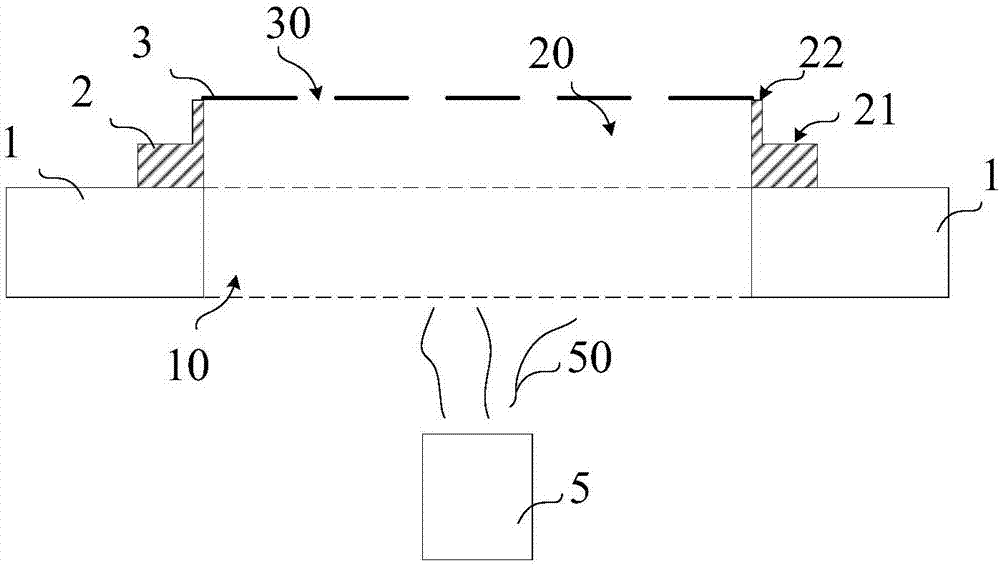

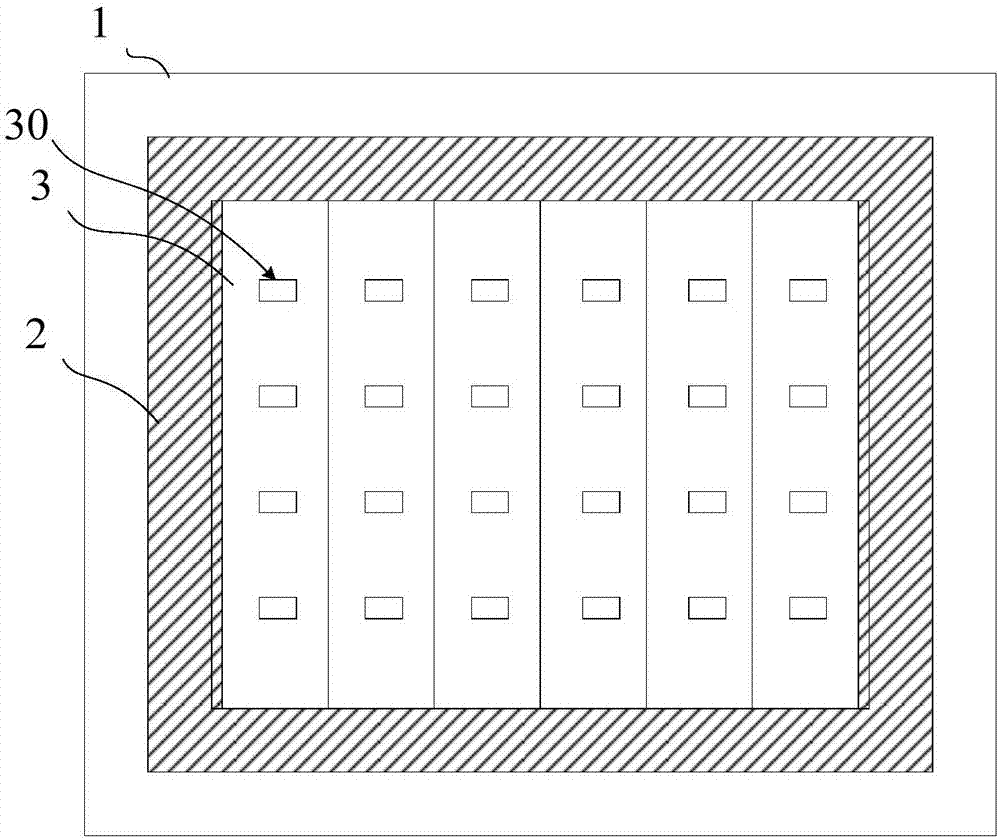

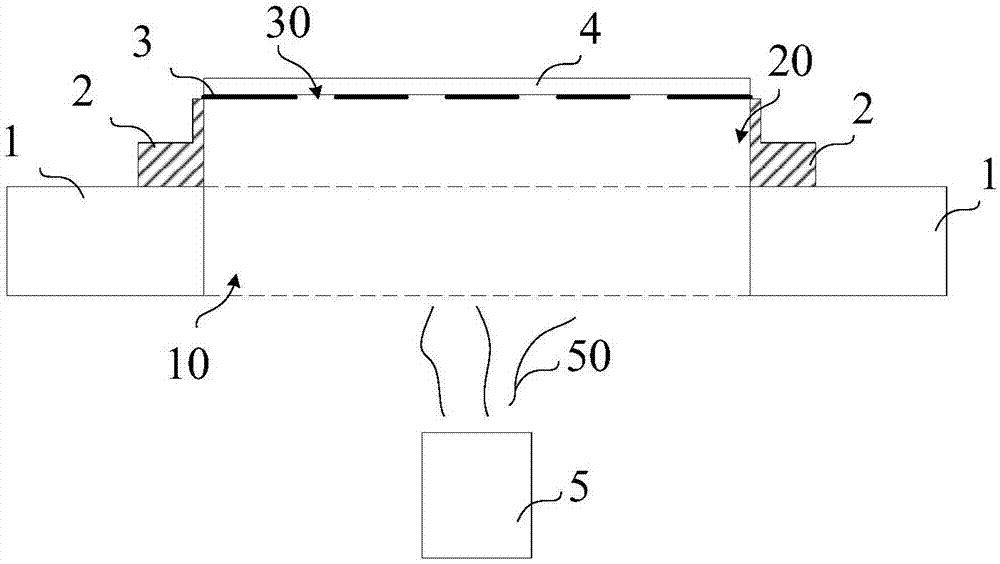

[0039] figure 1 is a schematic diagram of the structure of an evaporation system, figure 2 Yes figure 1 For a top view of the evaporation system provided, see figure 1 and figure 2 When performing organic vapor deposition, a mask stage 1 is set in the vapor deposition chamber, a frame 2 is set on the mask stage 1, and a metal mask 3 (mold) is set on the frame 2.

[0040]The outer contour of the mask stage 1 is columnar or table-shaped, and a first through hole 10 is provided in the middle of the mask stage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com