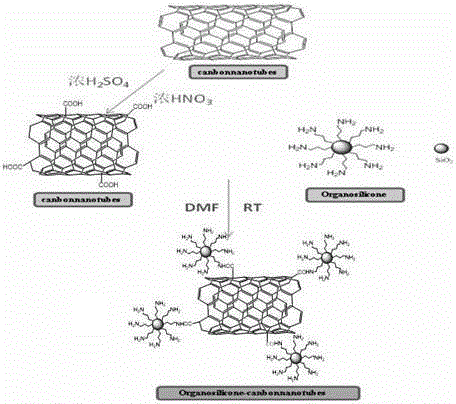

Carbon nanotube rodlike nanocomposite material modified by organic spherical silica and preparation method thereof

A technology of spherical silica and nanocomposite materials, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve problems such as unsuitable dispersion, limited application range, easy agglomeration of silica nanoparticles, etc., to achieve The product has the advantages of good structural unity, clear appearance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] First add 25ml of DMF to a 100ml single-necked flask, then add 1.2ml of organic spherical silica DMF sol and ultrasonically 20min to obtain a dilute organic silica sol solution, take a 100ml single-necked flask, add 40ml of DMF, and then add 20mg of carbon nanotubes to ultrasonically disperse for 2h. With the organic spherical silica DMF sol dilute solution that has been ultrasonicated at room temperature, use a constant pressure dropping funnel and drop the organic spherical silica DMF sol dilute solution at a rate of 1 to 3 drops per second to the constantly stirring In dilute carbon nanotube DMF solution, stir and react for 1h, then ultrasonically disperse for 30min, then continue to stir and react at room temperature for 10~12h, after the reaction is completed, ultrasonically for 1h, then filter with a 220nm organic filter, wash with DMF, and then ultrasonically disperse in In 150ml of DMF, the suction filtration was repeated 3 times until the redundant organic spher...

Embodiment 2

[0023] First add 25ml of DMF to a 100ml single-necked flask, then add 1.6ml of organic spherical silica DMF sol and ultrasonically 20min to obtain a dilute organic silica sol solution, take a 100ml single-necked flask, add 40ml of DMF, and then add 20mg of carbon nanotubes to ultrasonically disperse for 2h. With the organic spherical silica DMF sol dilute solution that has been ultrasonicated at room temperature, use a constant pressure dropping funnel and drop the organic spherical silica DMF sol dilute solution at a rate of 1 to 3 drops per second to the constantly stirring In dilute carbon nanotube DMF solution, stir and react for 1h, then ultrasonically disperse for 30min, then continue to stir and react at room temperature for 10~12h, after the reaction is completed, ultrasonically for 1h, then filter with a 220nm organic filter, wash with DMF, and then ultrasonically disperse in In 200ml of DMF, the suction filtration was repeated 3 times until the excess organic spherica...

Embodiment 3

[0025] First add 20ml of DMF to a 100ml single-necked flask, then add 0.7ml of organic spherical silica DMF sol and ultrasonically 20min to obtain a dilute organic silica sol solution, take a 100ml single-necked flask, add 40ml of DMF, and then add 20mg of carbon nanotubes to ultrasonically disperse for 2h. With the organic spherical silica DMF sol dilute solution that has been ultrasonicated at room temperature, use a constant pressure dropping funnel and drop the organic spherical silica DMF sol dilute solution at a rate of 1 to 3 drops per second to the constantly stirring In dilute carbon nanotube DMF solution, stir and react for 1h, then ultrasonically disperse for 30min, then continue to stir and react at room temperature for 10~12h, after the reaction is completed, ultrasonically for 1h, then filter with a 220nm organic filter, wash with DMF, and then ultrasonically disperse in In 100ml of DMF, the suction filtration was repeated 3 times until the redundant organic spher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com