Aluminum, silicon, copper and rare earth alloy material for metal mold casting and preparation method and application thereof

A metal mold casting and rare earth alloy technology, applied in the field of aluminum alloy materials and their preparation, can solve the problems of heavy shell weight, low hardness, poor corrosion resistance, etc., to save the heat treatment process, high hardness, and good corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

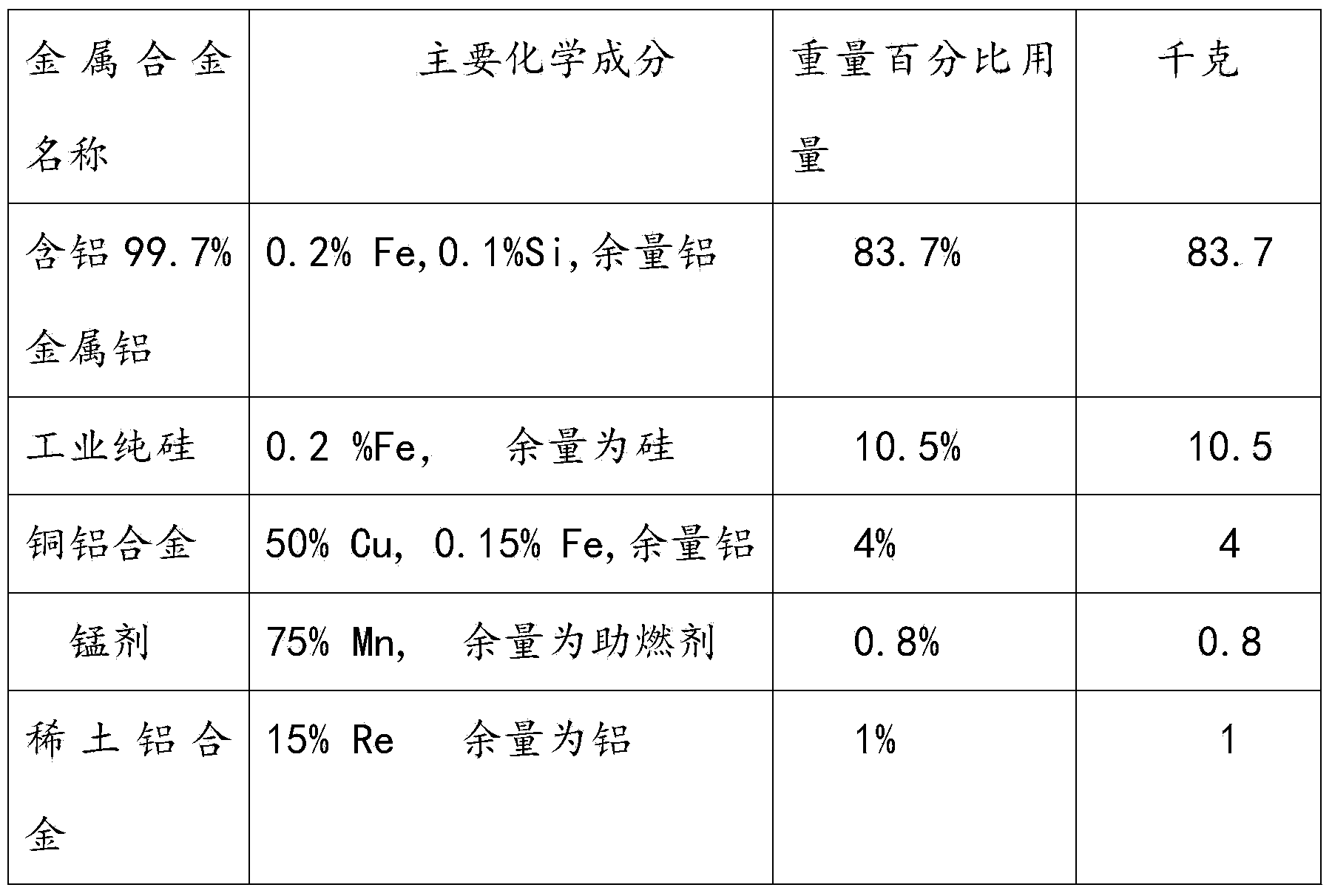

[0015] A. Calculate and weigh 10.5 kg of industrial pure silicon containing 99.8% silicon, 50% copper and 4 kg of copper-aluminum alloy, 0.8 kg of manganese agent containing 75% manganese, 1 kg of rare-earth aluminum alloy containing 15% rare earth metal, and 83.7 kg of metal aluminum containing 99.7% aluminum for standby;

[0016] The proportion of ingredients is:

[0017]

[0018] B. Put the metal aluminum ingot prepared in step A into the medium frequency induction furnace to melt first, then add industrial pure silicon, copper aluminum alloy, manganese agent in turn, and finally add rare earth aluminum alloy. The melting temperature is 716°C. The internal alloy solution is sampled and analyzed to analyze and detect the content of each chemical component, and adjust the content of each component according to the test data, and supplement the burnt part to make the content of each component meet the requirements;

[0019] C. The aluminum-silicon-copper rare earth alloy s...

Embodiment 2

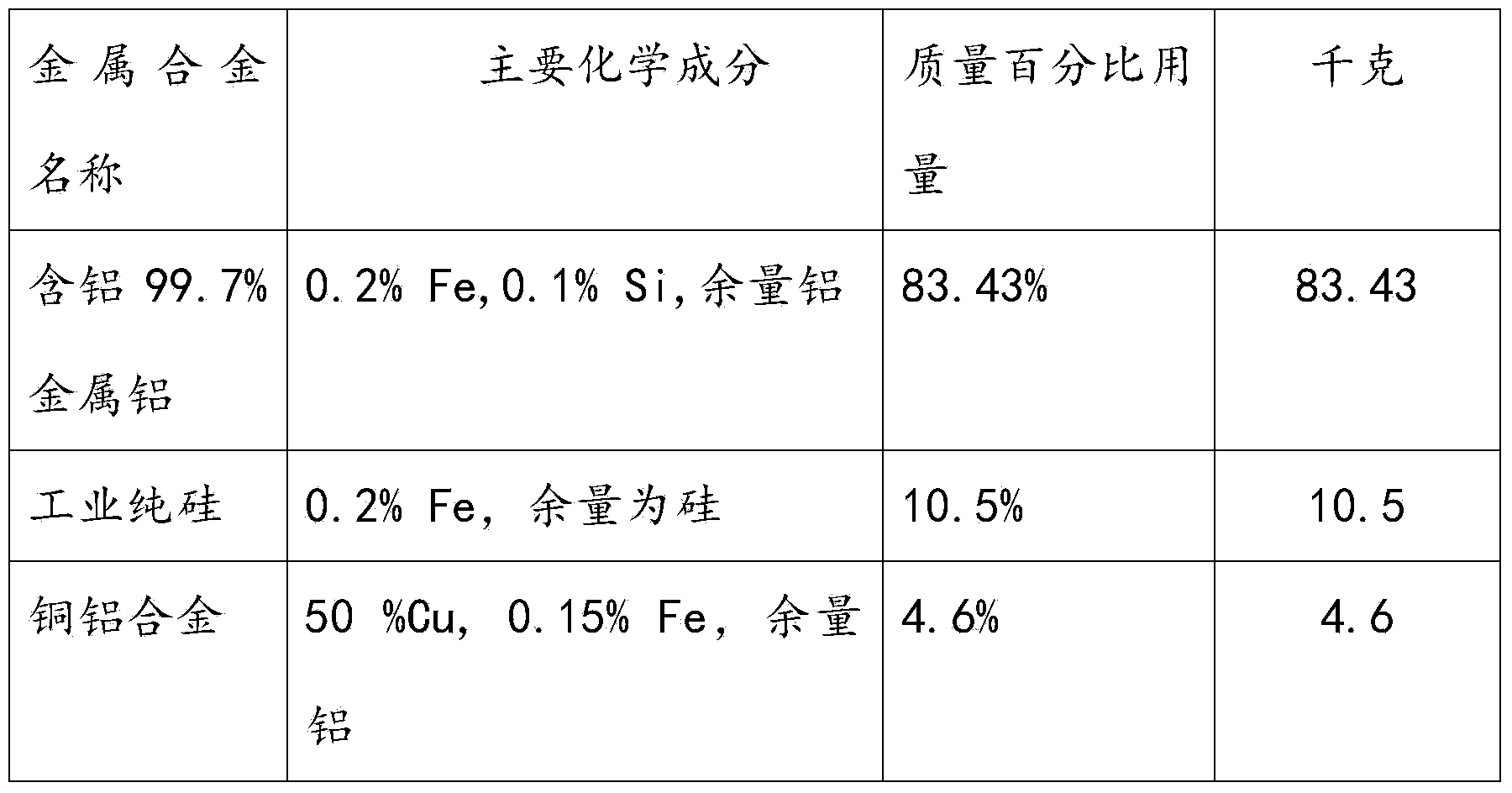

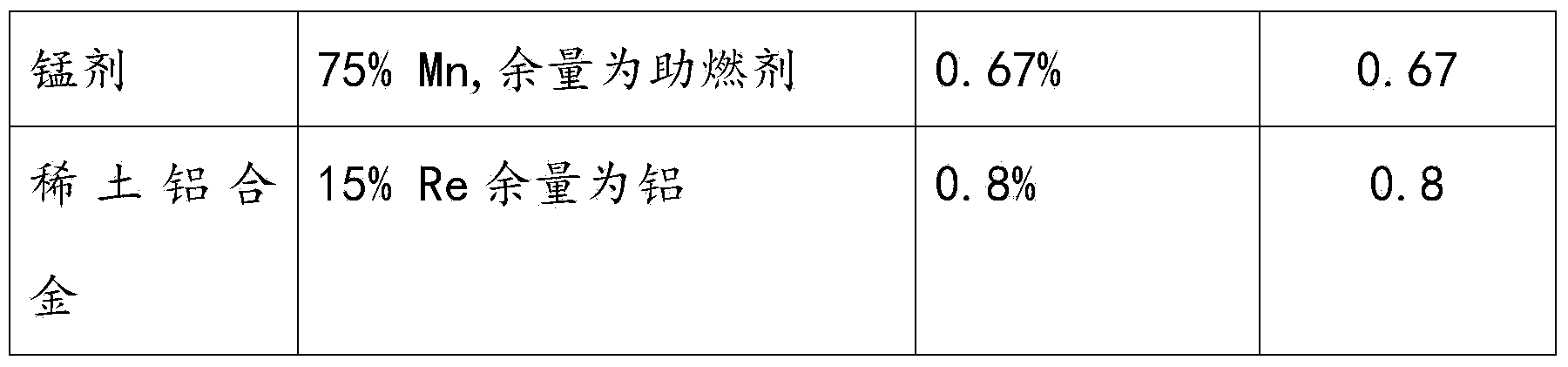

[0023] A. Calculate and weigh 10.5 kg of industrial pure silicon containing 99.8% silicon, 50% copper and % copper aluminum alloy 4.6 kg, manganese containing 75% manganese agent 0.67 kg, rare earth aluminum alloy containing 15% rare earth metal 0.8 kg, aluminum containing 99.7% aluminum 83.43 kg spare;

[0024] The proportion of ingredients is:

[0025]

[0026]

[0027] B. Put the metal aluminum ingot prepared in step A into the medium frequency induction furnace to melt first, then add industrial pure silicon, copper aluminum alloy, manganese agent in turn, and finally add rare earth aluminum alloy. The melting temperature is 705°C. The internal alloy solution is sampled and analyzed to analyze and detect the content of each chemical component, and adjust the content of each component according to the test data, and supplement the burnt part to make the content of each component meet the requirements;

[0028] C. The aluminum-silicon-copper rare earth alloy solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com