Metal mold low-pressure casting process for cast-aluminum gearbox body of high-speed train

A technology of low-pressure casting and high-speed trains, which is applied in the field of cast aluminum gearbox casting, which can solve the problems that restrict the performance of cast aluminum gearbox casings, and achieve the effects of good dimensional stability, high casting yield, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

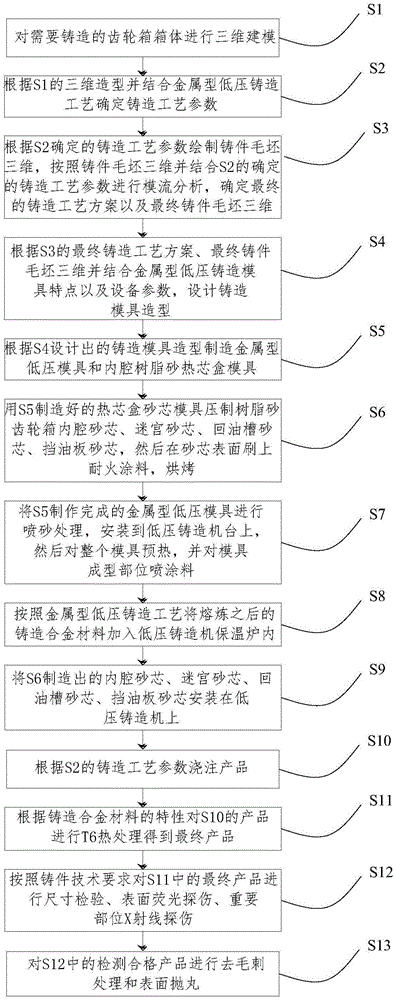

[0041] This embodiment proposes a high-speed train cast aluminum gear box metal mold low-pressure casting process, including the following steps:

[0042] S1. Use 3D software to carry out 3D modeling of the high-speed train gearbox box that needs to be cast according to the technical requirements;

[0043]S2. According to the three-dimensional modeling of S1 and combined with the metal mold low-pressure casting process, the casting process parameters are determined: the chemical composition of the alloy material, the pouring system, the machining allowance, and the parting surface;

[0044] S3. Draw the three-dimensional casting blank according to the casting process parameters determined in S2, use the mold flow software to analyze the mold flow according to the three-dimensional casting blank and combined with the casting process parameters determined in S2, and continuously optimize and determine the final casting process plan and the final three-dimensional casting blank ;...

Embodiment 2

[0056] This embodiment proposes a high-speed train cast aluminum gear box metal mold low-pressure casting process, including the following steps:

[0057] S1. Use 3D software to carry out 3D modeling of the high-speed train gearbox box that needs to be cast according to the technical requirements;

[0058] S2. According to the three-dimensional modeling of S1 and combined with the metal mold low-pressure casting process, the casting process parameters are determined: the chemical composition of the alloy material, the pouring system, the machining allowance, and the parting surface;

[0059] S3. Draw the three-dimensional casting blank according to the casting process parameters determined in S2, use the mold flow software to analyze the mold flow according to the three-dimensional casting blank and combined with the casting process parameters determined in S2, and continuously optimize and determine the final casting process plan and the final three-dimensional casting blank ...

Embodiment 3

[0071] This embodiment proposes a high-speed train cast aluminum gear box metal mold low-pressure casting process, including the following steps:

[0072] S1. Use 3D software to carry out 3D modeling of the high-speed train gearbox box that needs to be cast according to the technical requirements;

[0073] S2. According to the three-dimensional modeling of S1 and combined with the metal mold low-pressure casting process, the casting process parameters are determined: the chemical composition of the alloy material, the pouring system, the machining allowance, and the parting surface;

[0074] S3. Draw the three-dimensional casting blank according to the casting process parameters determined in S2, use the mold flow software to analyze the mold flow according to the three-dimensional casting blank and combined with the casting process parameters determined in S2, and continuously optimize and determine the final casting process plan and the final three-dimensional casting blank ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Absolute density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com