Method for calculating thickness of blank shell at position of continuous casting roller row and solidification tail end of casting machine

A technology of solidification end and continuous casting roll, applied in special data processing applications, geometric CAD, design optimization/simulation, etc., can solve the problems of inaccurate calculation, affecting the accuracy of calculation results, calculation process adaptability, slow calculation speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

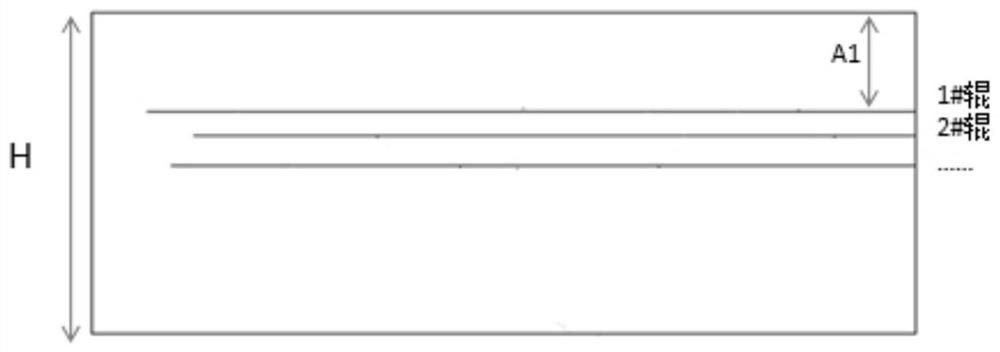

[0015] For example: for a steel billet of 200×200 square meters, the distance between the inner and outer arcs is H=195mm measured on a low magnification, and the positions of the roll rows are 13.5 meters for 1# roller, 15 meters for 2# roller, and 16.5 meters for 3# roller; continuous casting The casting speed is 1.2 m / min; it is known that the slab length is low. Solve the billet shell thickness at each roll of the steel in this process of continuous casting machine and the solidification end position when it is fully solidified.

[0016] According to the known conditions, that is, the nominal thickness of the slab is M=200mm, and the thickness of the slab at the low multiple is H=195mm;

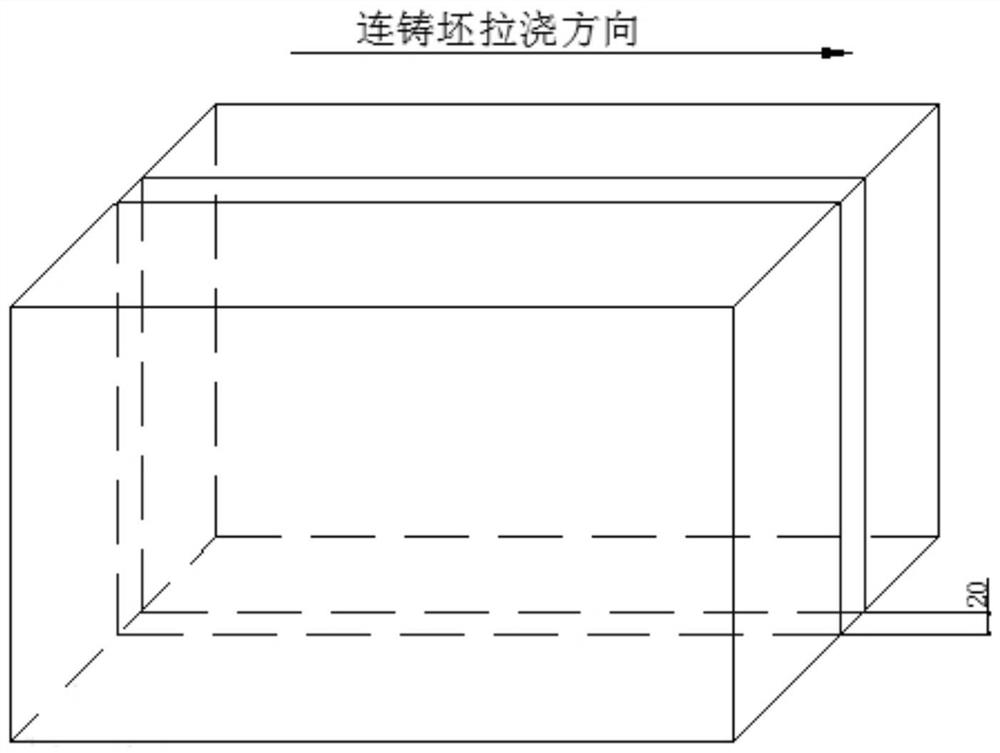

[0017] Cut a continuous casting slab low-magnification sample with a length equivalent to the cross-sectional size of the casting slab, saw along the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com