Compositions, methods and devices for high temperature lead-free solder

A composition, solder technology, applied in the direction of electrical components, welding/cutting media/materials, welding equipment, etc., can solve problems such as poor mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

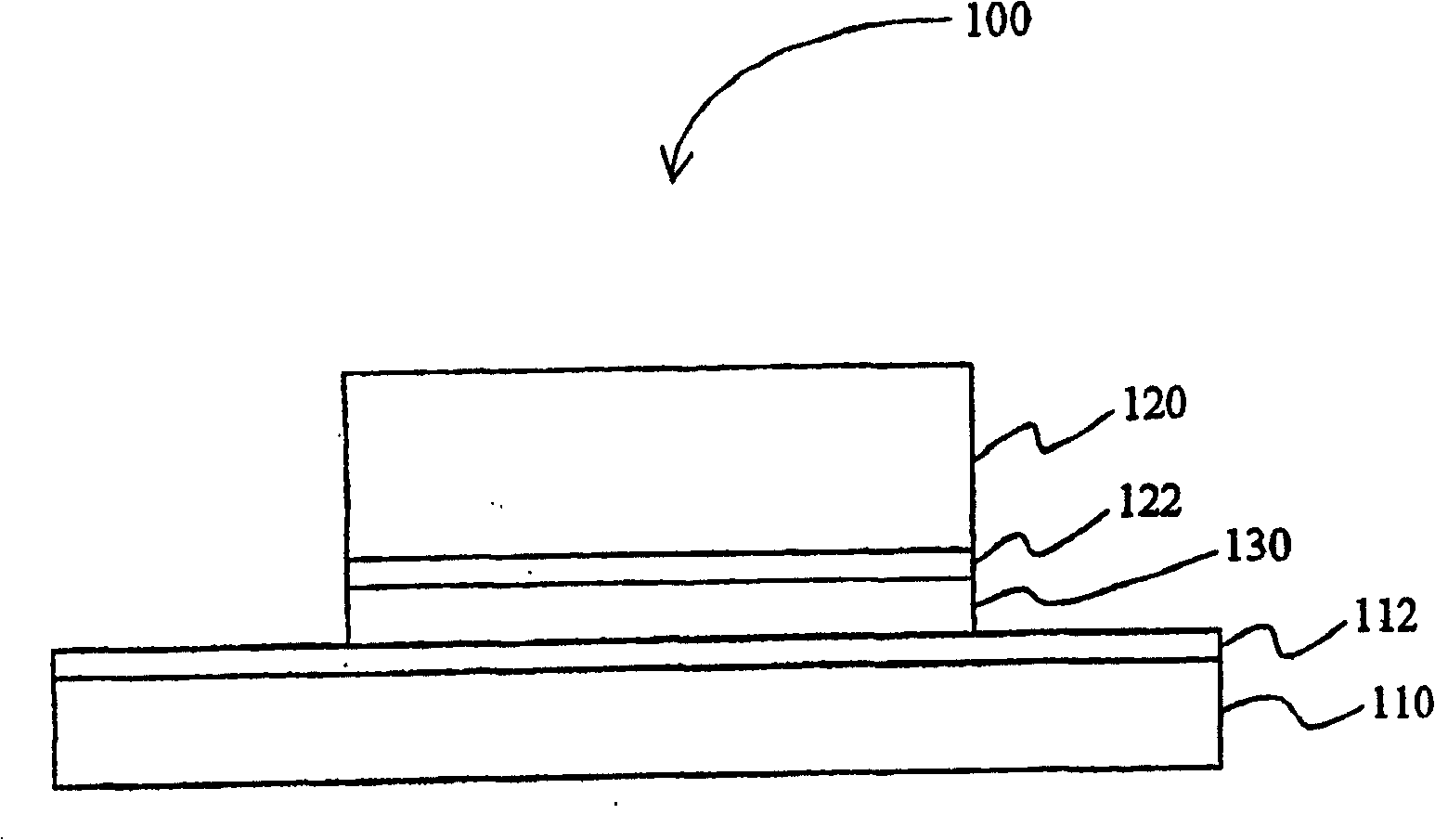

Image

Examples

Embodiment Construction

[0027] Solder joints are often subjected to shear loads due to differences in the coefficients of thermal expansion of different materials. Therefore, alloys joining these materials are particularly required to have low shear modulus and thus good resistance to thermomechanical fatigue. For example, low shear modulus and good thermal-mechanical fatigue resistance help avoid chip cracking when mounting chips, especially when relatively large chips are bonded to a solid support.

[0028] Based on the known modulus of elasticity of pure metals, Ag and Bi show some solid-state mutual solubility and the Ag-Bi system does not contain intermetallic phases or intermediate phases, the Ag-Bi alloy of the present invention is stable at room temperature The shear modulus is in the range of 13-16 GPa (assuming that the shear modulus at room temperature is an additive property - ie the mixture rule described below). The 13-16GPa range of the shear modulus at room temperature of the alloy i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com