Method and apparatus for injection molding of semisolid alloys

A molding method and semi-solid technology, applied in the field of semi-solid alloy injection molding and equipment, can solve the problems of semi-solid slurry leakage, increased processing cost, erosion damage, etc. The effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The main difference between the injection molding method provided by the present invention and existing methods is that it does not require the use of conventional rotating screws or pistons. In this way, equipment manufacturing and operating costs can be significantly reduced while retaining most of the characteristics of traditional injection molding machines.

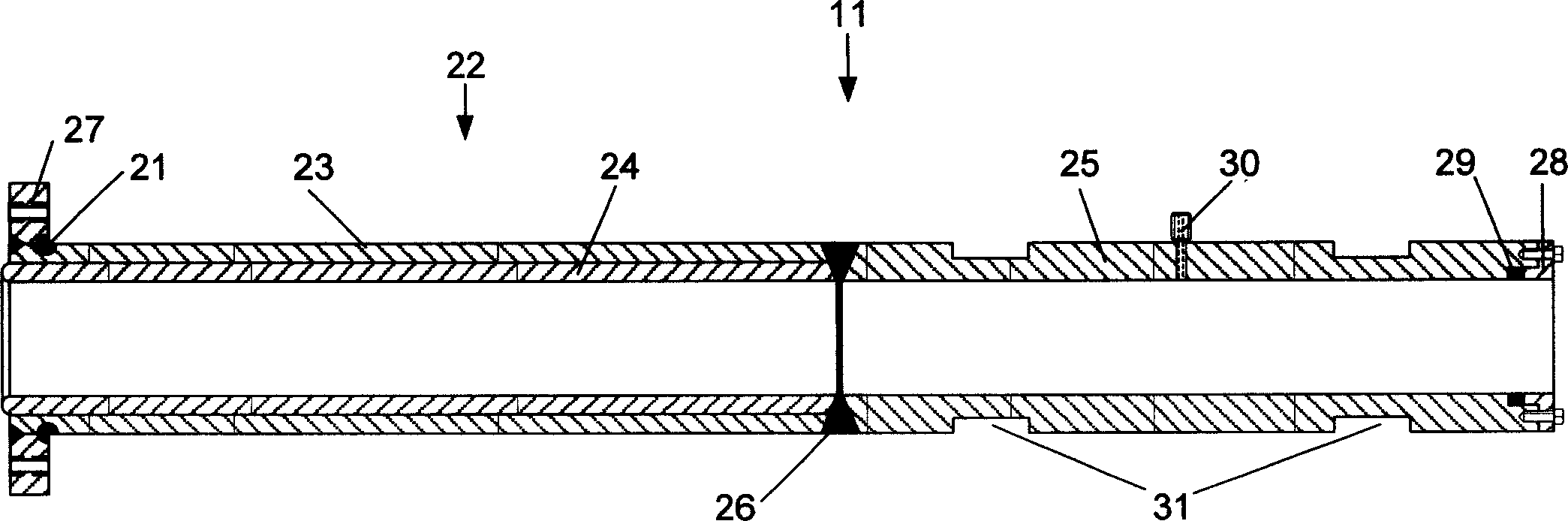

[0035] The method is realized through the following steps: a non-dendritic raw material rod is fed into a slurry sleeve, and a given length section of the head of the non-dendritic raw material rod is heated to a point between its solidus line and liquidus line. A certain temperature generates a semi-solid slurry, and the solid part of the non-dendritic raw material rod is used as a disposable piston to inject the semi-solid slurry in front of it into the mold cavity.

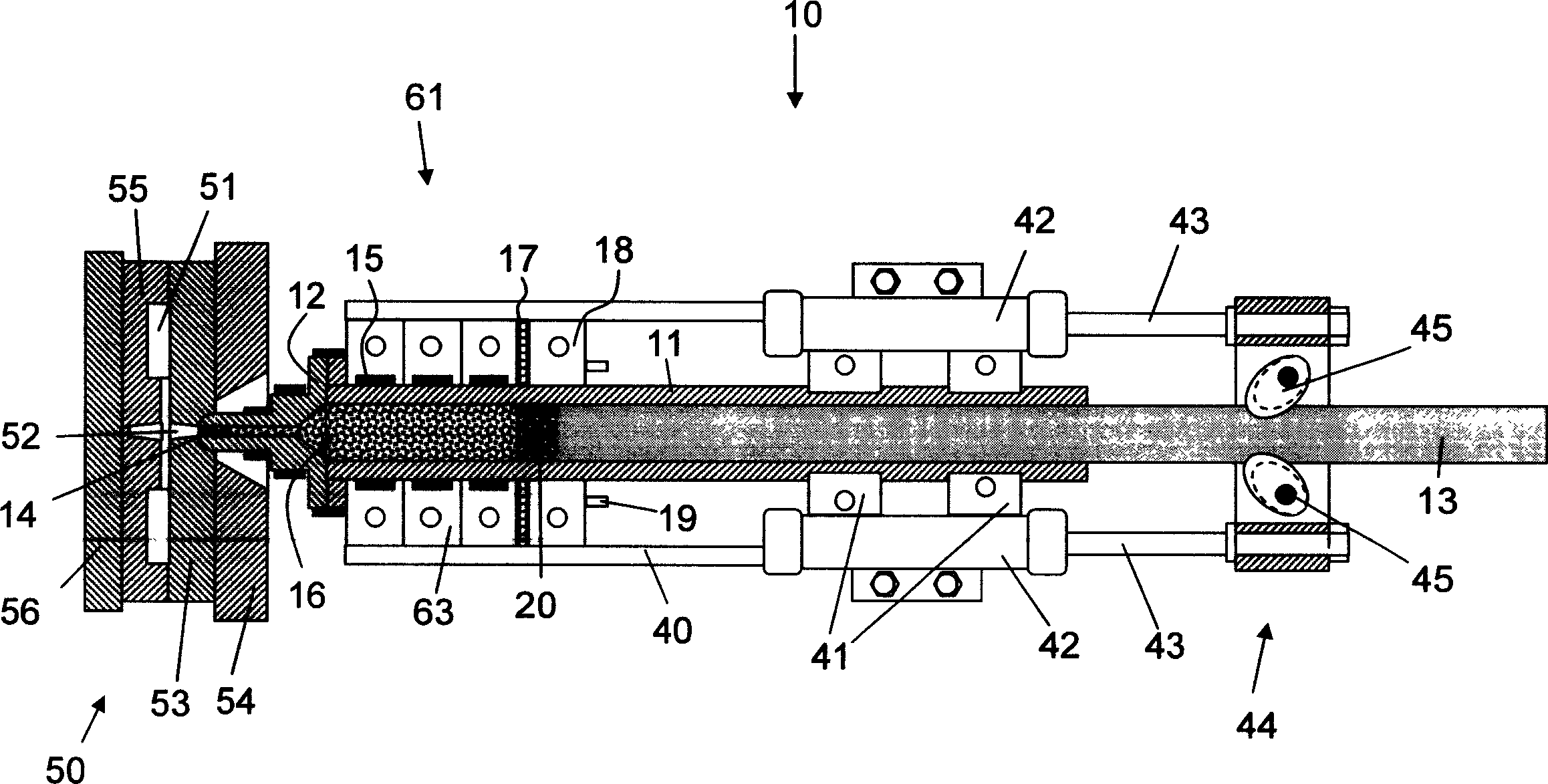

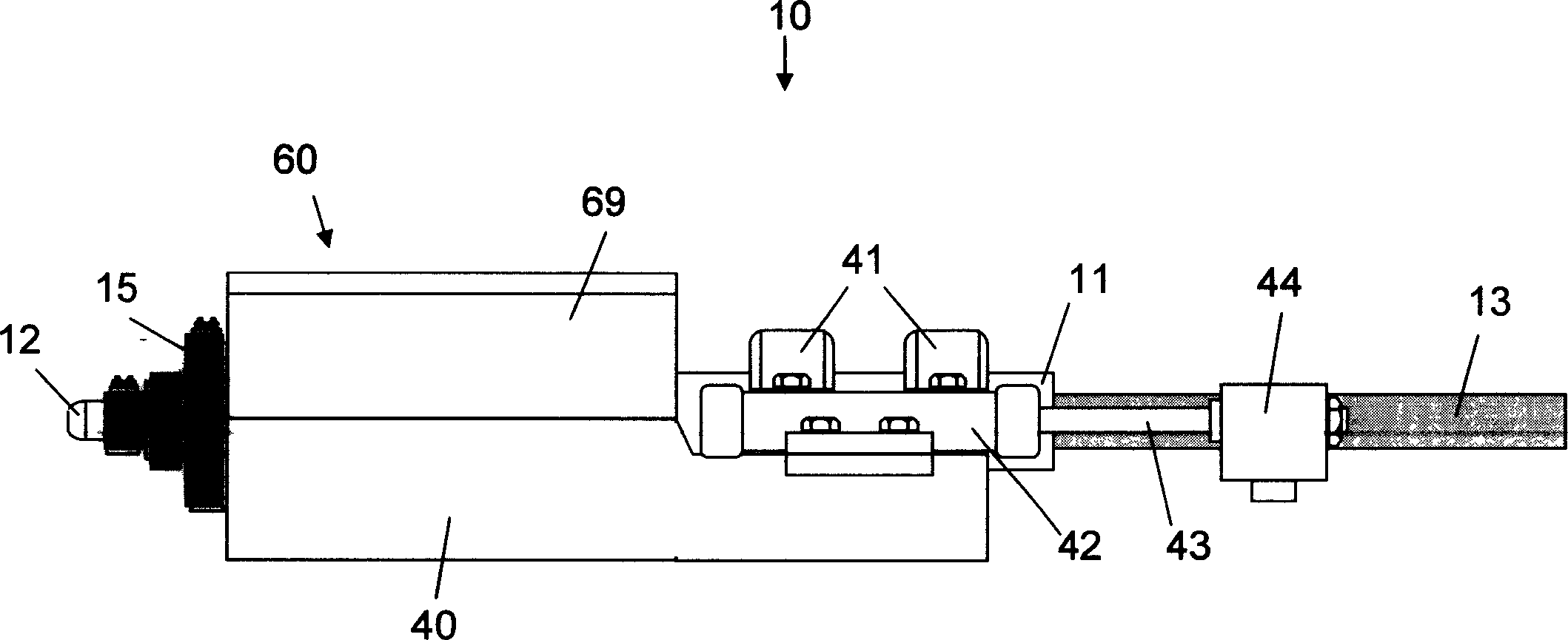

[0036] The above steps can be used as figure 1Shown injection molding machine (10) to complete. The injection molding machine (10) comprises...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com