Method for preparing non-liquating monotectic alloy material and device thereof

A technology of monotectic alloy and segregation, which is applied in the field of preparation technology of homogeneous monotectic alloy material, can solve the problems of long research period, limitation of sample size and equipment, and degradation of bearing material performance.

Active Publication Date: 2010-11-24

新兴发展集团有限公司

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, there are certain problems in various methods: when using microgravity conditions to solidify, it is very difficult to obtain long-term microgravity on the ground, and it is expensive to prepare materials under microgravity in space, and the research cycle is long; In the rapid solidification scheme, although the monotectic alloy with approximately uniform distribution can be prepared, the sample size and equipment are greatly limited; when the atomization powder is used, and then sintered at low temperature, although the macroscopic non-segregation-free alloy can be prepared Monotectic alloy material, but its mechanical properties are still not comparable to alloys prepared by solidification, and its performance will be greatly reduced when used as a bearing material

Therefore, so far, monotectic alloys with uniform distribution of the second phase have not been prepared on the ground at conventional solidification rates.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

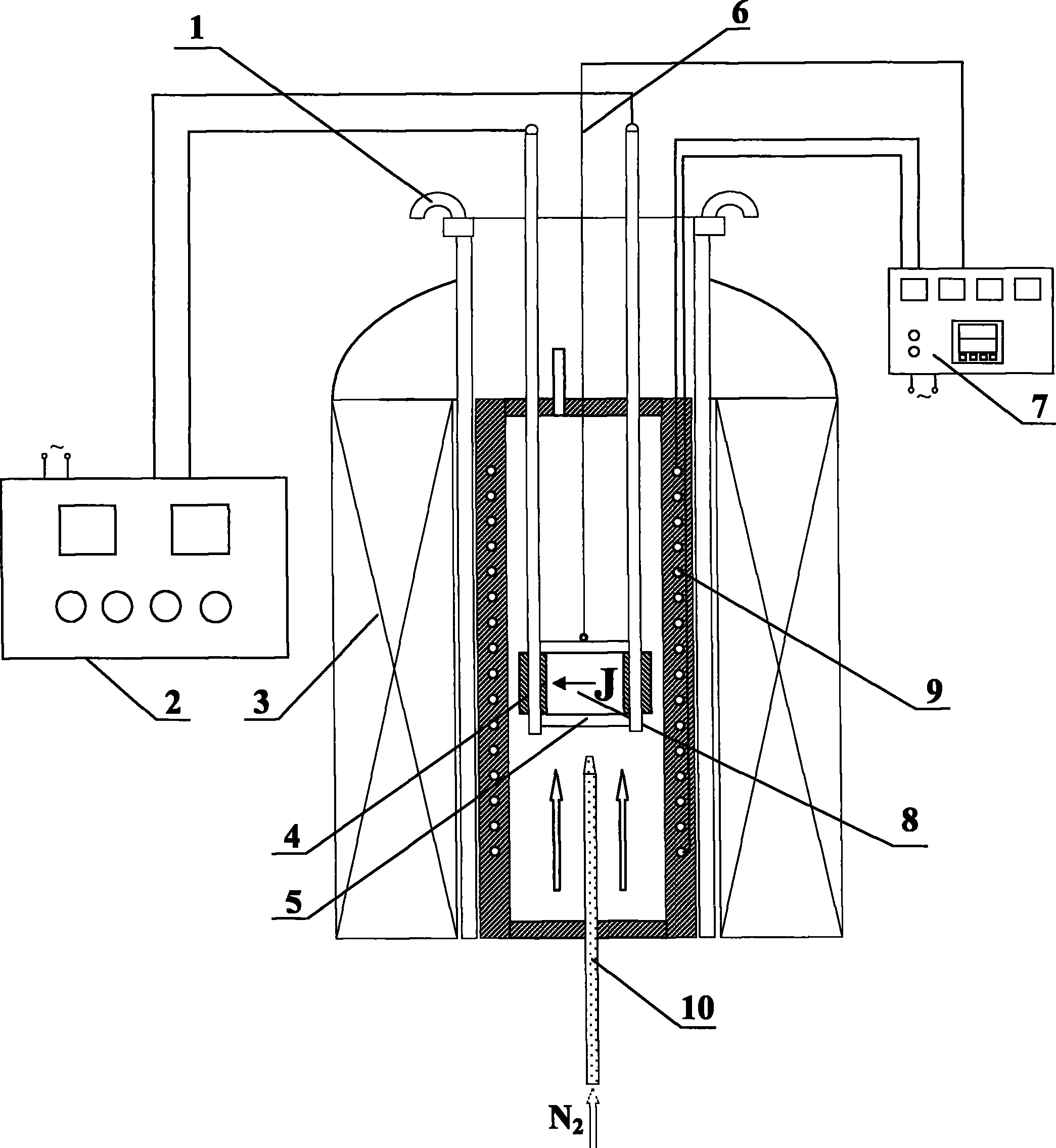

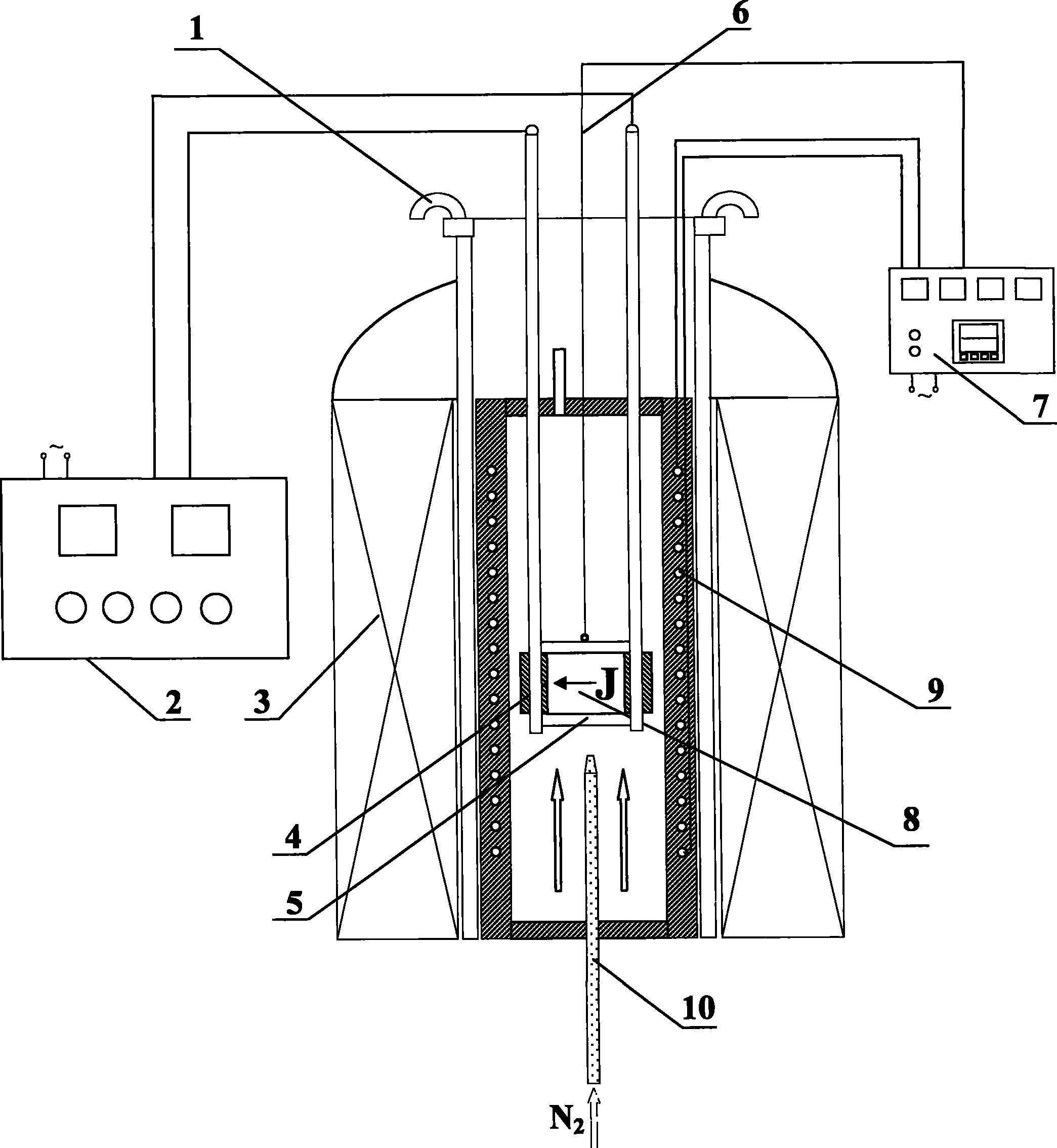

The present invention relates to process and apparatus for preparing monotectic crystal alloy without segregation, and belongs to the field of homogeneous monotectic crystal alloy preparing technology. The present invention features that the segregation of the second phase in alloy is inhibited by means of the cooperation of steady strong magnetic field and alternate current so as to obtain monotectic crystal alloy with homogeneously distributed second phase. The process of the present invention includes the following steps: heating binary alloy with monotectic crystal component inside a crucible by means of alternate current inside a strong magnetic field a superconductive magnet generates under the protection of inert gas at temperature over the liquid temperature for several hours, andlowering the temperature in controlled speed while applying AC in proper intensity and frequency to below the solid temperature, and further cooling to room temperature to obtain the monotectic crystal alloy.

Description

A method and device for preparing a monotectic alloy material without segregation technical field The invention relates to a method and a device for preparing a monotectic alloy material without segregation, and belongs to the technical field of homogeneous monotectic alloy material preparation technology. Background technique The monotectic alloy with the second phase evenly distributed in the matrix is an important functional material, and it exhibits excellent performance in the fields of high-performance bearing materials, electrical contact materials, electrochemical materials, and superconducting materials. However, this alloy has special metallurgical characteristics: during the solidification process of the alloy, there is a liquid-liquid immiscible zone. Due to the difference in density between the liquid phase that precipitates first and the original melt, the liquid phase stratifies, and finally forms a mutual phase. Immiscible two phases, so that the uniform ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22F3/02

Inventor 钟云波王江任忠鸣

Owner 新兴发展集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com