Welded metal and titanium dioxide flux-cored wire

A technology for welding metal, titanium dioxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

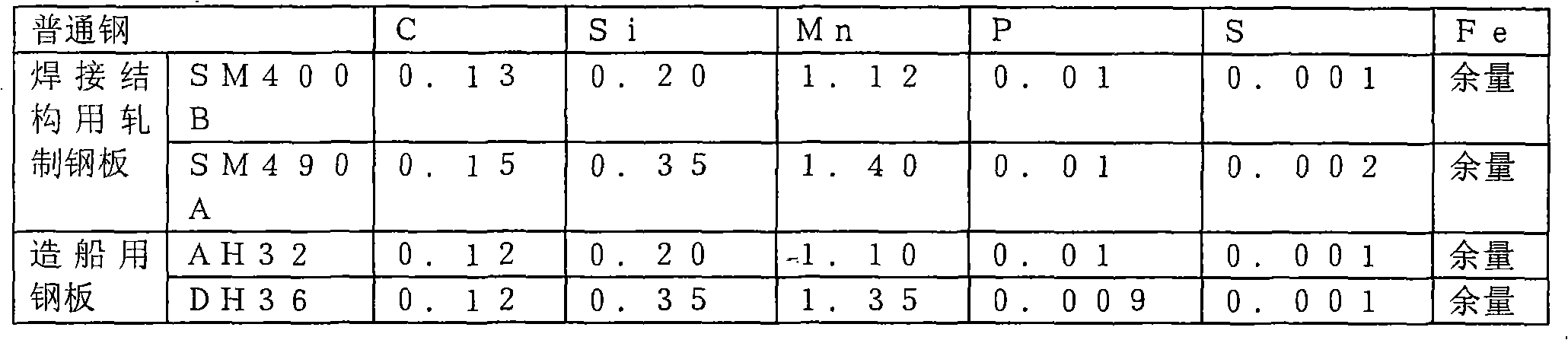

[0032] Hereinafter, the present invention will be specifically described with reference to the drawings. First, the reasons for adding components and limiting the composition of the weld metal of the present invention will be described.

[0033] "B: 0.005% by mass or less (excluding 0)"

[0034] P is added as an element that improves the toughness of the weld metal part, but if the content of B exceeds 0.005% by mass, the high temperature crack resistance will be poor, so it is preferably 0.005% by mass or less.

[0035] "N: 0.0045 to 0.02% by mass"

[0036] N is an element that ensures the strength of the weld metal portion. In addition, N cures B as BN, thereby having an effect of improving high-temperature crack susceptibility. However, these effects are insufficient when N is less than 0.0045% by mass. On the other hand, if the N content exceeds 0.02% by mass, the toughness of the weld metal part will be significantly reduced. Therefore, N is preferably 0.0045 to 0.02...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com