Filling flux welding wire

A filling welding and welding wire technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of low-temperature toughness reduction, lack of high-temperature crack resistance, and no display, etc., to achieve the goal of welding metal machinery Excellent properties, excellent high temperature crack resistance, excellent welding workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The filled flux welding wire of the present invention will be described in detail.

[0030] The flux-filled welding wire of the present invention is used for welding steel plates made of mild steel or high-tensile steel. In addition, the flux-filled welding wire of the present invention is also suitable for gas-shielded arc welding, and exhibits excellent effects in single-face butt joint welding, and the welding method is not particularly limited.

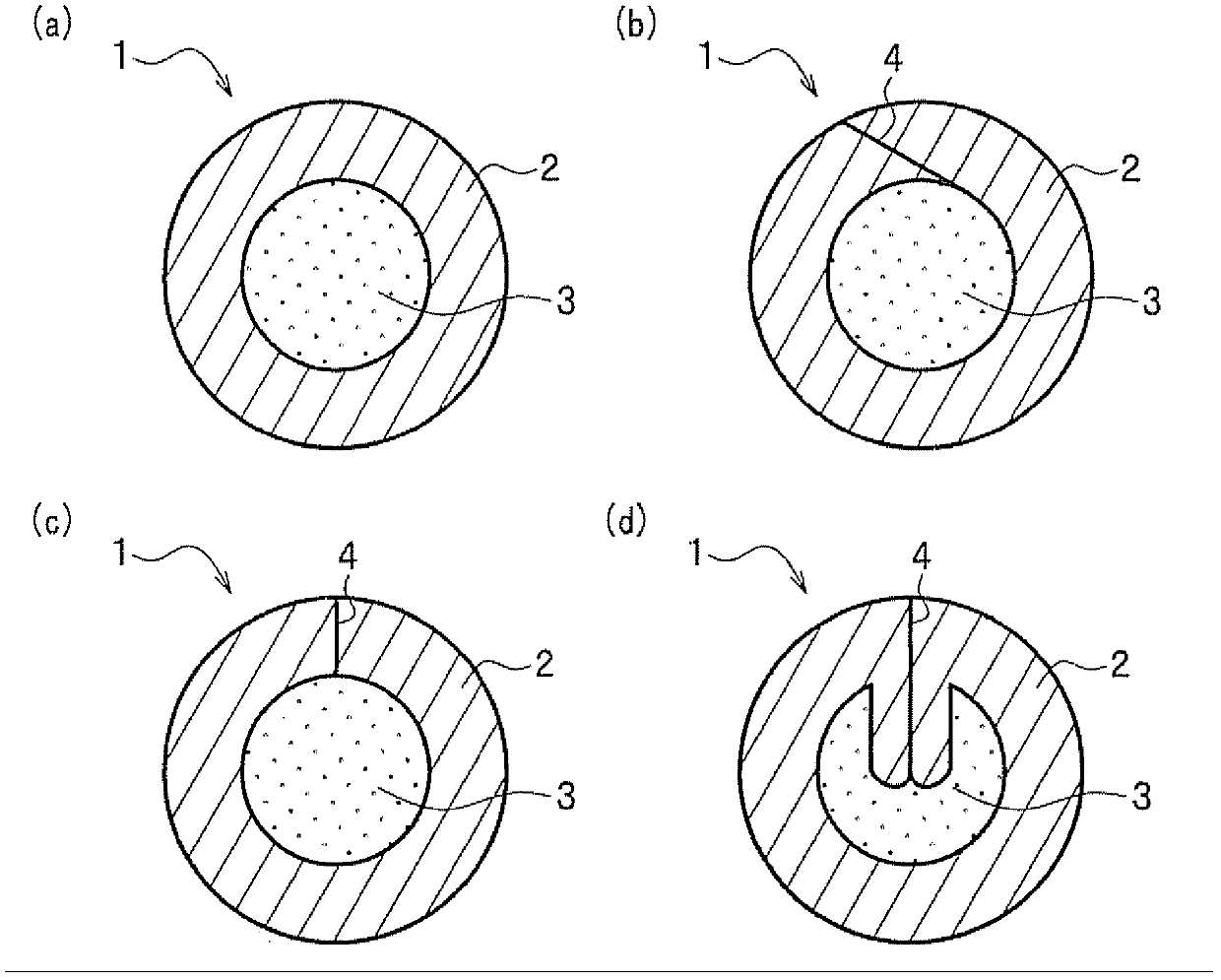

[0031] Such as figure 1As shown in (a) to (d), a flux-filled welding wire (hereinafter referred to as a welding wire) 1 is composed of a cylindrical steel sheath 2 and flux 3 filled in the cylinder. In addition, the welding wire 1 can also be in any of the following forms: figure 1 The seamless type shown in (a) is filled with flux 3 in the cylinder of the jointless steel sheath 2; figure 1 (b)-(d) shows such a seam type in which flux 3 is filled in the cylinder of steel sheath 2 with joint 4 .

[0032] Furthermore, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com