Flux-cored wire

A technology of flux-cored welding wire and welding wire, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc. It can solve the problems of poor weld bead shape, poor welding workability, mechanical properties (poor toughness, etc.) of welded metal, and achieve quality Excellent, excellent high temperature crack resistance, excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

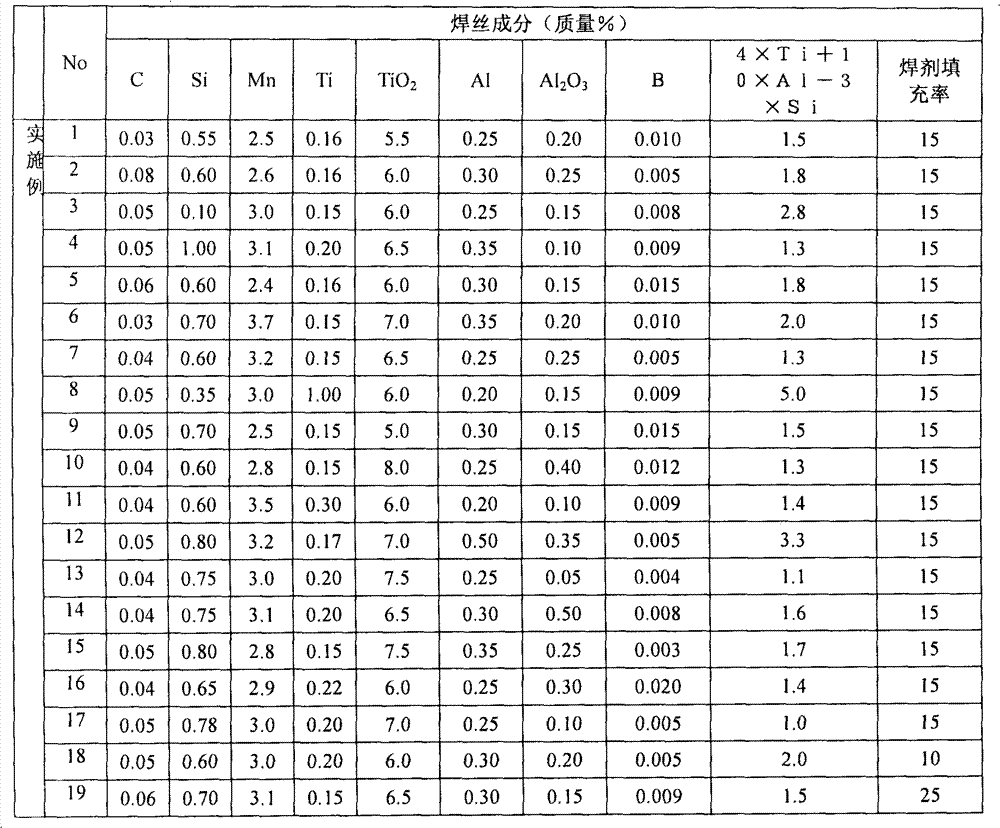

[0052] The flux-cored welding wire of the present invention will be specifically described by comparing Examples satisfying the requirements of the present invention and Comparative Examples not satisfying the requirements of the present invention.

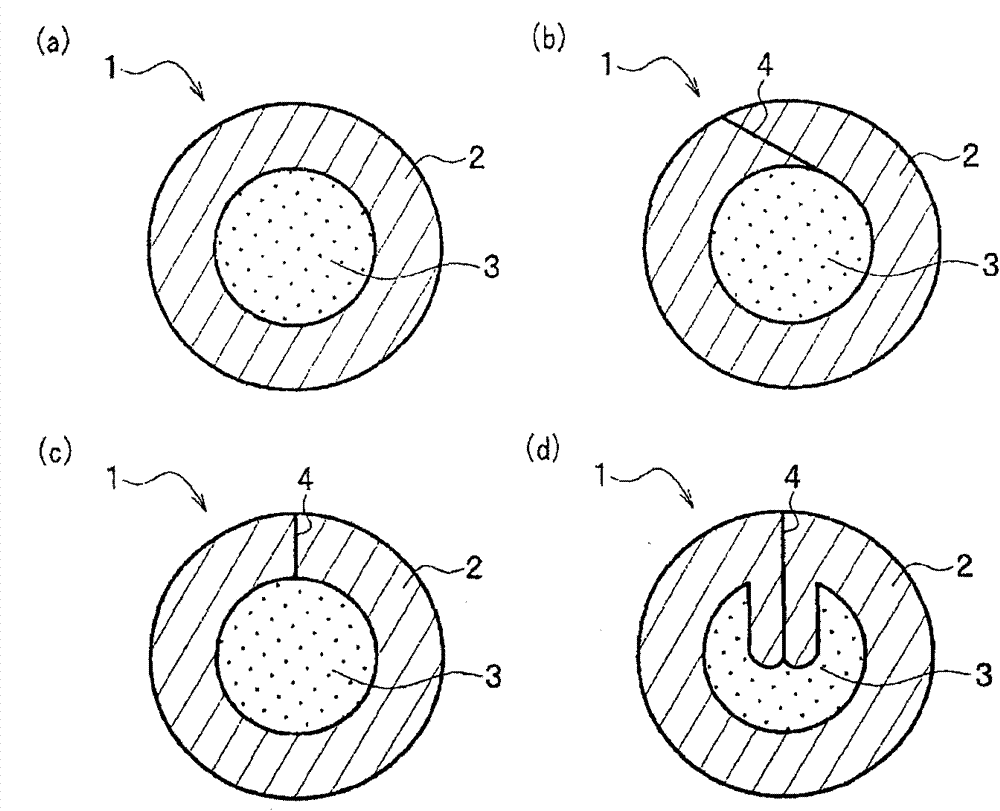

[0053] In steel sheath (steel used contains C: 0.03% by mass, Si: 0.02% by mass, Mn: 0.25% by mass, P: 0.10% by mass, S: 0.007% by mass, the balance is Fe and unavoidable impurities) Fill the inner side with flux, and make a wire diameter of 1.2mm composed of the wire components shown in Table 1 and 2. figure 1 Welding wire 1 shown in (b) (Example: No. 1-19, Comparative example: No. 20-40).

[0054] In addition, the welding wire component was measured and calculated by the following measuring method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com